HYDRAULIC ROTARY UNIONS – ROTARY JOINTS FOR MACHINE TOOLS

Hydraulic Rotary Unions — Rotary Joints for Machine Tools

Rotary Joints are required in almost all industries to transfer fluids from stationary to rotating machine parts. Some applications are simple to solve with standard rotary joint solutions. However, in more complex applications, such as machine tools, the performance of the machine depends to a large degree on the correct selection of the rotary joint. Maieroffers a complete range of rotary joints and sealing systems to suit individual customer specifications.

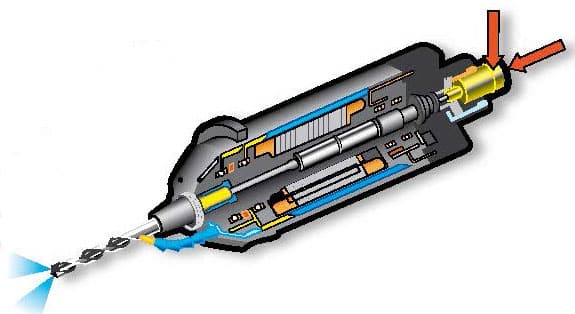

Cooling through the electro-spindle:

Traditionally, tool tips have been cooled by supplying coolant from an external source. However, in processes such as milling, this method of cooling does not provide optimum performance and decreases the service life of the tools, particularly in the case of high speeds of rotation. State-of-the-art machine tools use systems that supply cooling fluid through the electro-spindle.

Advantages:

Selection of the rotary joint for coolant:

TESS Technology:

The TESS technology (Thermal Expansion Sealing Systems) is an internationally patented Maier development. The system works like a classical closed seal when used with liquid coolant. In case of pressurized dry air, dry operation or minimal lubrication, the system detects an increase in temperature and reduces the specific closing pressure applied to the seal faces without separating the sealing surfaces.

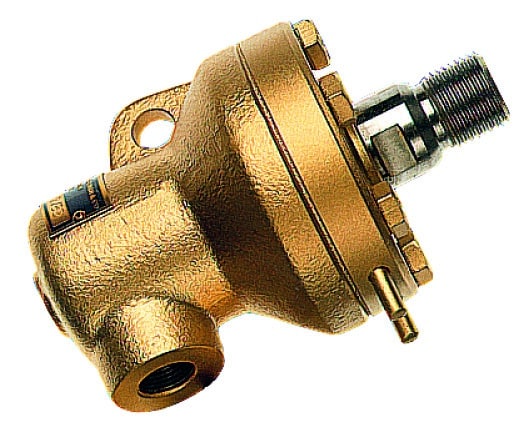

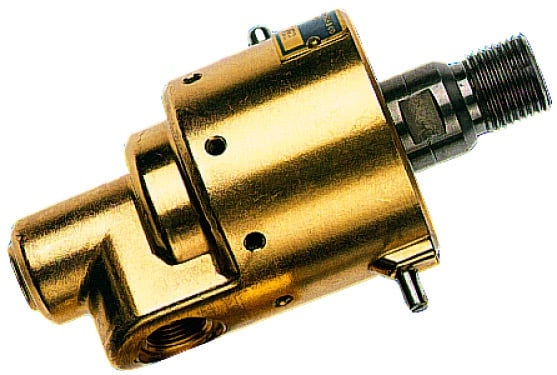

K Series:

Series K consists of three basic versions: K 21, KT 21 and KT 41. Rotary joint type K 21 is only suitable for coolant. Rotary joint type KT 21 with TESS technology is resistant to pressure peaks. Suitable for coolant, dry operation without limitation, minimal quantity lubrication (MQL) and dry air under pressure and speed. Rotary joint type KT 41 with TESS is designed for high pressure and speed.

They share common characteristics such as:

K 21 C, KT 21 C and KT 41 C with axial inlet.

K 21 B, KT 21 B and KT 41 B with radial inlet.

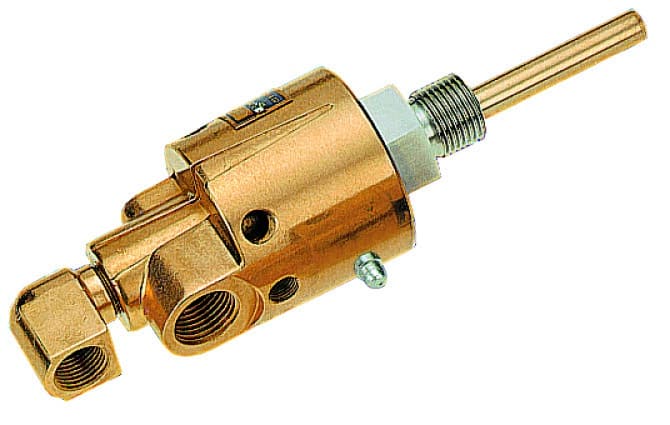

KL Series:

Series KL rotary joints are designed for liquid coolants. Passage in one direction, closed seals. The housing is made of stainless steel and anodized aluminum. A labyrinth seal protects the bearings against fluid. Adapted rotating mechanical seals made of silicon carbide and carbon graphite. Ball bearings. Drain holes in the housing. KLT is the alternative with TESS technology with thermal relief of the seal. KLT is suitable for coolant, dry operation and MQL (minimal quantity lubrication). Outside dimensions identical to series KL.

KL 11 C and KLT 11 C with axial inlet.

KL 11 B and KLT 11 B with radial inlet.

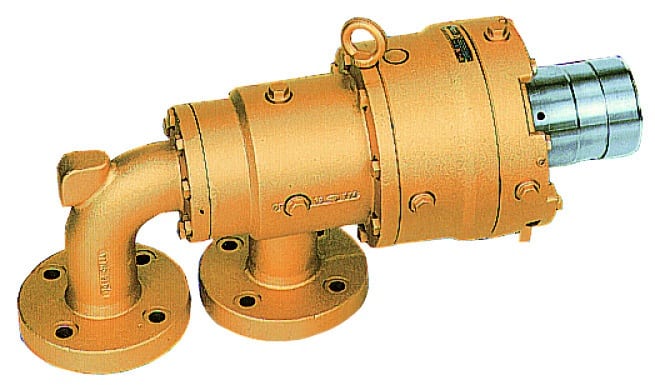

Combijoint:

With Combijoint, different types of rotary joints such as MP, MPV, K, DP and electric slip rings can be combined. Hydraulic oil, compressed air, gas, water, grease, coolant, current and electric signals can be transferred. Combijont versions are the most versatile and flexible way of transferring fluids. Frequently, only a single type of seal is selected for multi-passage rotary joints, usually a radial seal, to seal the passage of different media under different working conditions. This considerably reduces the service life of the rotary joint. Combijoint allows you to combine different seal technologies that best suit a specific fluid. Mounting several rotary joints in series also lets you select different materials, depending on the specific requirements. This results in a costeffective and reliable solution. In case of leaks, it is sufficient to repair the failed rotary joint without having to open the other rotary joints since only one housing is affected. The connecting flange can be sized to customer requirements for this solution.

Maier is a supplier and rotary union manufacturer for various applications including construction, mechanical, marine, and industrial.