What is a die-splitter machine used for? Why is it so useful?

Written by Ing. Alessio Caramaschi

The die-splitter machine, invented in 1993 by Armando Caramaschi, owner of the Universal 1972 company, is an equipment that simplifies the assembly and maintenance operations of the tools, reduces its time significantly and finally, last but not least, makes it safe 100% a maneuver that otherwise would have serious risks for the operator linked to heavy loads that are hung from chains and turned in the air.

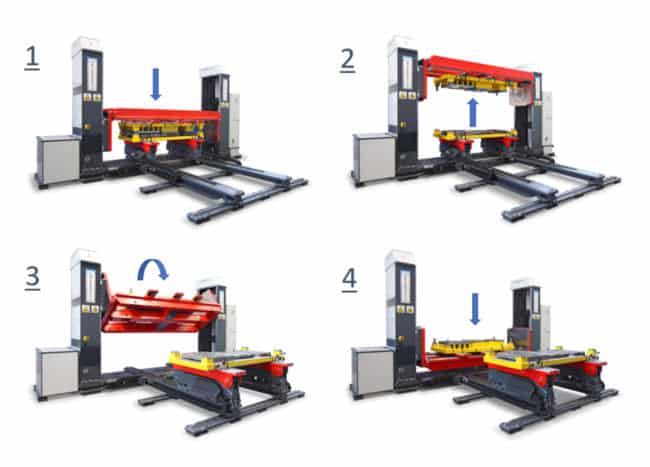

Let’s see the detailed operation of the die-splitter:

1: Receive the tool on the lower base

2: The lower motorized table takes the tool inside the machine

3: The tool, aligned in position, is fixed to an upper table (the fixing can be manual by T-clamping or through permanent magnets)

4: The upper table, moving on Rexroth ball bearing guides, runs up and divides the tool in two parts

5: The lower part can return to the external position

6: The top table rotates by 180 ° (or as much as you want)

At the end of this process, which can last only 2 or 3 minutes depending on the size of the machine and the type of clamping chosen, the tool is perfectly open with the two bases facing upwards and ready for assembly, maintenance or cleaning.

Before the invention of this machine, opening a tool was a very delicate operation that required the operator’s experience.

Today, we are faced with a changed working landscape, where young operators have to open and rotate tools of increasingly important dimensions.

Often, these are equipment that are the result of very expensive investments and that could be compromised by a careless maneuver, without even thinking about what would happen if a chain breaks and the tool ended up on the operator. This scenario that looks like a movie instead has sadly repeated itself, as often read in the newspapers.

Fortunately, safety has now become an imperative and more and more companies all over the world are dedicating a budget to secure their department, tools and above all to prevent any accidents at work.

Those managers who have chosen to invest in a die-splitter machine have understood that the company can be made safe by also creating a consequent economic saving so that the measures go hand in hand.

Wherever this happened, the manager was praised by his colleagues who made the tool handling job safer and easier and by the management that experienced the decrease in time that was lost.

In summary, the main advantages for using the UNIVERSAL1972 die-splitter machine:

1: Greater safety for the operator

2: Greater safety for the tool

3: Reduction of maintenance times

4: Devices such as presses, trucks and overhead cranes are free for other operations

5: Improved company efficiency

To calculate your savings, check out this link: https://universal1972.com/en/calculate-your-saving/

To learn more, check out our product page here: https://www.icfluid.com/products/press-products/hydraulic-press-products-die-splitter-turnover-device/

If you have any questions about the machine or want to learn more, contact IC-Fluid Power, Inc. today to speak with one of our application specialists!

Recent Blogs

See You at the...

Registration is now open for the 2022 Industry & Economic Outlook Conference (IEOC). The show will take place from August… Read More »See You at the 2022 Industry & Economic Outlook Conference!

read moreCongratulations, Victoria!

Our Marketing Intern, Victoria Lower, has just graduated from Bowling Green State University with a Bachelor of Science in Technology.… Read More »Congratulations, Victoria!

read moreHonoring and Remembering

Honoring and remembering those who have served on this Memorial Day and every day. From all of us here at… Read More »Honoring and Remembering

read more