Domin Servo Valves + Hänchen Cylinders in Testing

October 15, 2025

Test Cylinders + Servo Valves in Test and Simulation

Domin Lead Time Zero

Choosing a Hänchen Test Cylinder

Domin + Hänchen Testing Case Study

Rotary Vane Actuators in Testing

Exploring How Cylinders and Servo Valves Work Together in Test and Simulation

In automotive testing, collecting accurate data is the foundation for building quality cars. To understand how a vehicle truly performs, tests need to be carefully designed to simulate real driving conditions.

In these tests, hydraulic cylinders and actuators act like the “muscles” of the system. They create the push and pull forces needed to reproduce road vibrations and other driving stresses. Here, servo valves receive electronic signals and convert them to mechanical movement by controlling which direction the oil can flow, allowing the cylinders to quickly adjust its position, speed, and force.

Together, these components can form a testing setup that combines both strength and precision, delivering repeatable results and clear data for better vehicle design.

Testing Applications and Challenges

Hydraulic components face very different demands depending on whether the test is quasi-static or dynamic.

Each test setup must be designed to match these specific conditions.

Static Testing

Static tests or quasi-static tests, such as seat or steering tests, involve slow, controlled movements where precision is more critical than speed. Since system stress is relatively low, single-rod, non-hydrostatic hydraulic components are often sufficient.

Application characteristics:

Dynamic Testing

Dynamic testing involves rapid cycles and high frequencies. These conditions put much greater demands on actuators, valves, and the test frame itself.

Application characteristics:

How We Combat These Challenges

We overcome these challenges through careful engineering of cylinders and servo valves that work together to deliver accuracy, durability, and control. With a rigid, stiff cylinder, the servo valve then ultimately defines the performance.

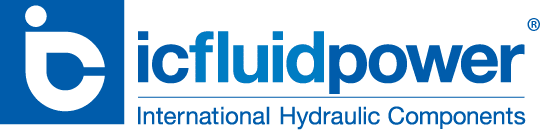

Cylinders

Sealing and guiding systems

The cylinder cover uses seals and guiding elements to limit friction, stick-slip, and leakage. One example is our floating gap seal, which is surrounded by oil to deliver extremely low friction at small amplitudes and low frequencies. For highly-dynamic applications, hydrostatic style cylinders are used, which offer nearly no friction.

Surface finishes

The cylinder’s sliding surfaces can be highly honed and polished with a crosshatch finish to support lubrication, smooth motion, and reduced wear on seals and components. This also supports reduced friction.

Solid steel construction

For highly dynamic applications where hydrostatic cylinders are used, the cylinder body can be machined from a single steel block to create precise bore tolerances and high rigidity. This also allows for exact sizing for optimum performance and right-sized HPU components.

Servo Valves

Motor technology

When the valve drive uses compact brushless motors, it can achieve a high amount of torque for the same given electrical input. This enables accurate, stable control under high frequencies and pressures, which is especially present in harsh dynamic applications.

Position sensors

Using magnetic hall-effect sensors can provide excellent control accuracy in a lightweight design, unlike traditional bulky linear transducers that offer only average resolution.

Advanced control algorithms

Optimized control algorithms allow valves to handle demanding step inputs, high speeds, and extreme frequencies for accurate, repeatable and clean data.

A Real World Test Example

Durability Testing of Vehicle Shakers

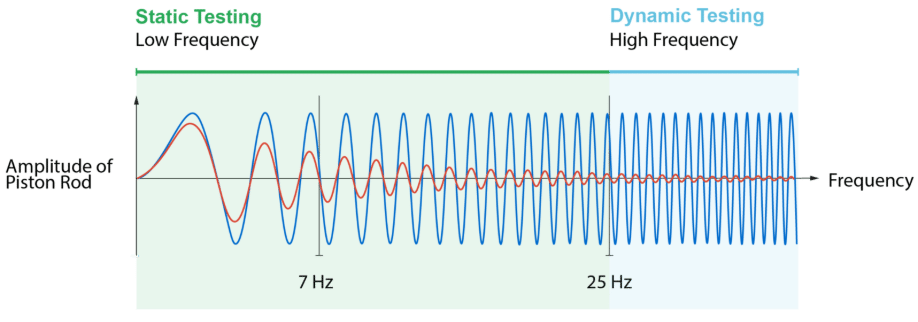

In a four‑post shaker rig, the vehicle sits on four pads, each driven by a hydraulic hydrostatic double-rod actuator beneath the wheel. These actuators apply controlled displacements and forces that replicate vibrations from potholes, rough pavement, and other road conditions up to 80 Hz.

The servo valve continuously meters oil flow to the cylinder in real time, ensuring the piston follows the test controller’s signal precisely.

This coordination gives engineers dependable data on suspension response, ride comfort, and vehicle durability.

Domin’ New Initiative: Lead Time Zero

Do More with Less Waiting

Lead Time Zero is Domin’s response to long-accepted industry lead times. Where traditional suppliers operate with lead times of 12-16 weeks, Domin’s core product range is in stock and can be shipped immediately from our Ohio warehouse.

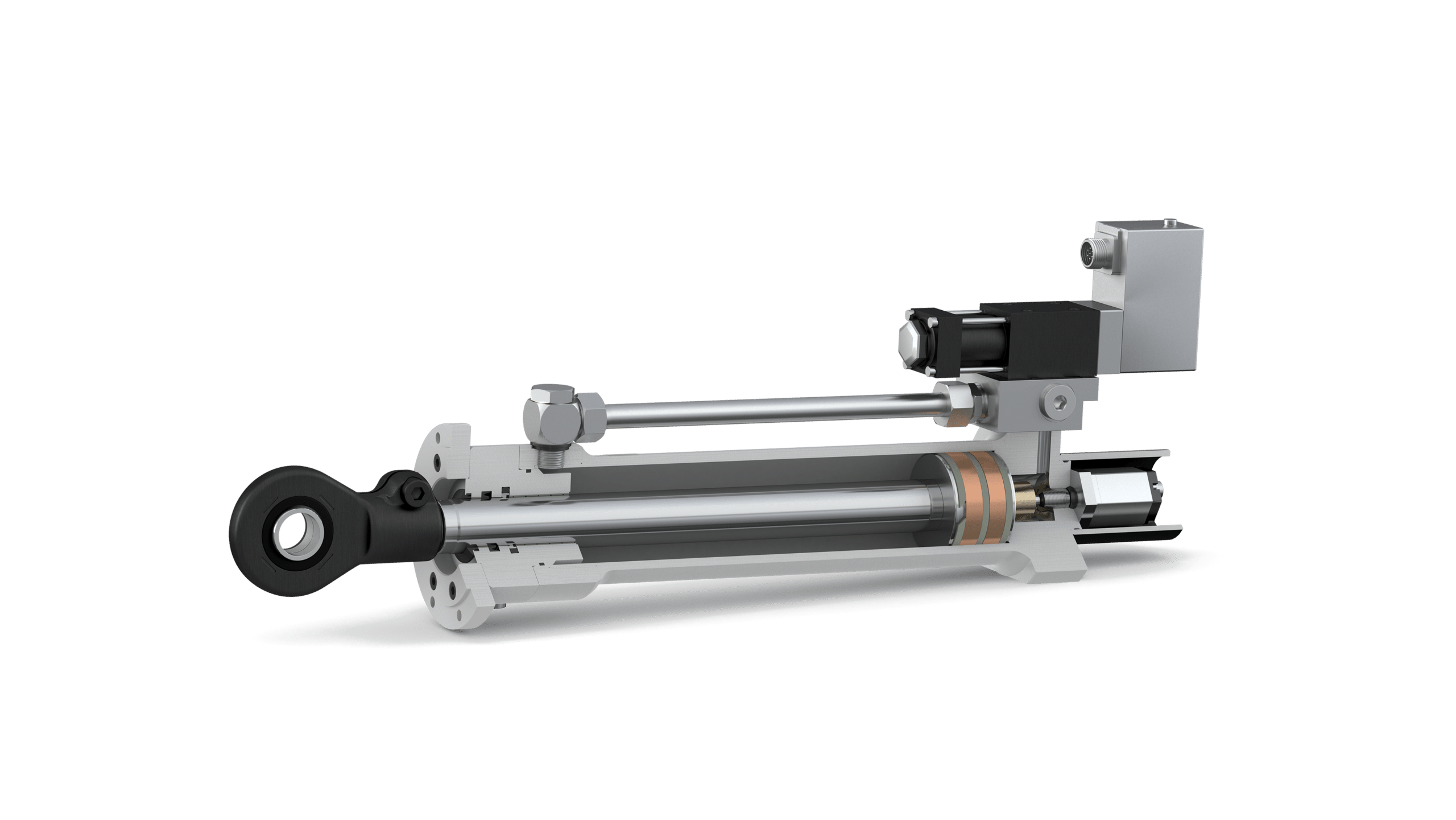

Choosing the Right Hänchen Test Cylinder

Hänchen hydraulic test cylinders are engineered for the precision and durability needed in the testing market. The range extends from lightweight servo actuators operating up to 25 Hz for static testing to high-frequency cylinders exceeding 100 Hz for dynamic applications (limited only by the capabilities of the servo valve).

Which series is right for you?

First, consider the demands of your testing application. There are 3 different series of Hänchen test actuators. Each series offers increasing capabilities.

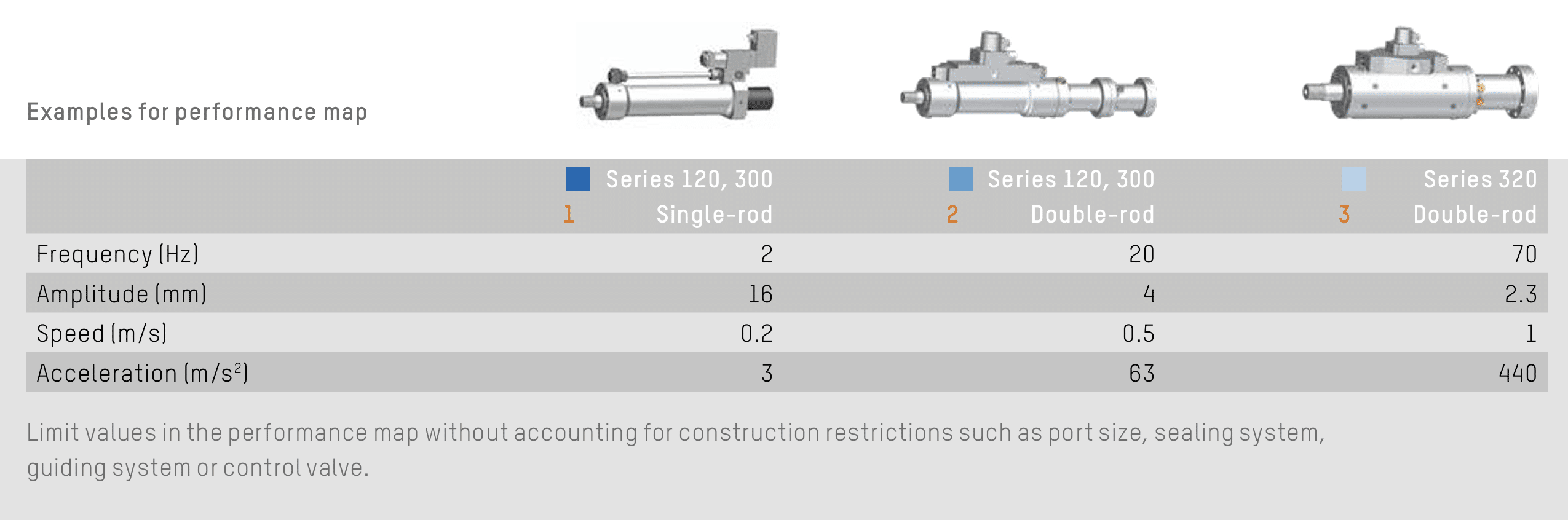

Series 120 and 300 – Light-Duty Test Actuators

If only simple testing tasks need to be accomplished, Series 120 and 300 servo cylinders offer the optimal price to performance ratio. These cylinders are especially suited for test tasks with long strokes.

Series 120 Specs

Series 300 Specs

Series 320 – Heavy-Duty Hydrostatic Test Actuators

The Series 320 hydraulic test cylinder is your best option for good, clean data in demanding applications at every frequency range. These cylinders are especially suited for high speeds and can reliably bear high lateral forces with excellent precision.

Series 320 Specs

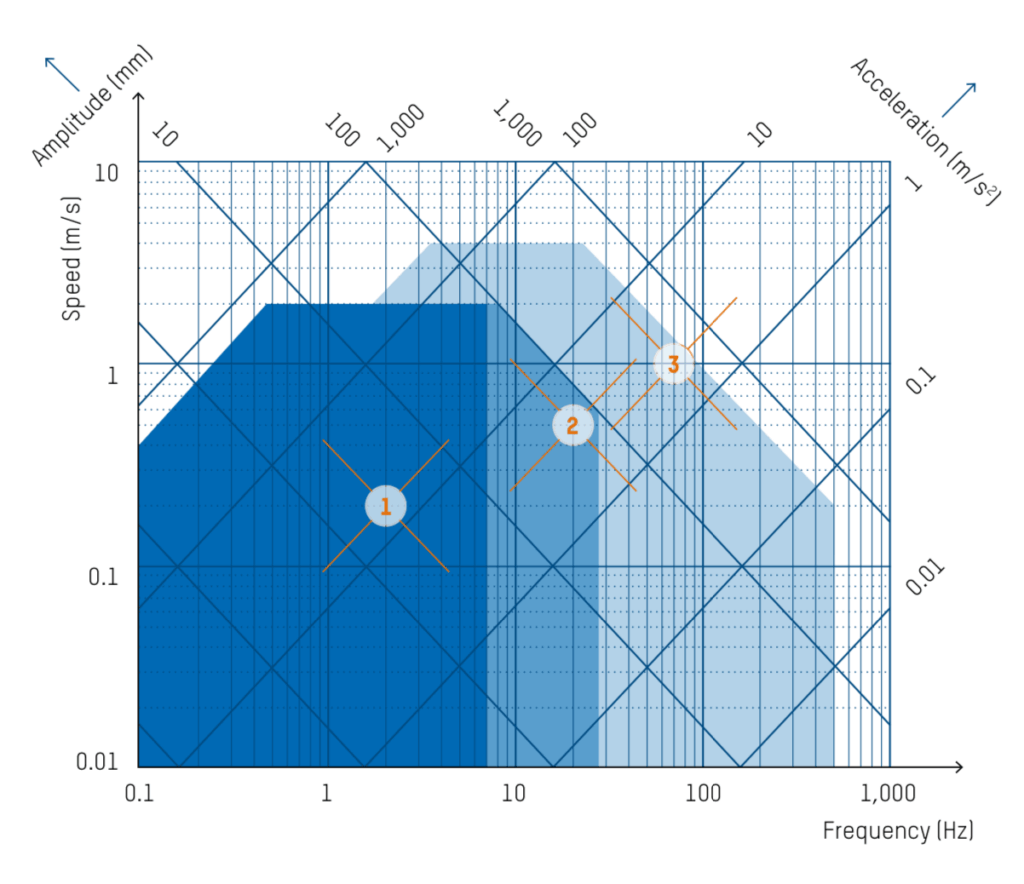

Example Performance Map

The map below serves for orientation purposes and shows the dynamic movement of a hydraulic drive during sinusoidal oscillation. The performance classes of the different cylinder designs define the possible applications.

DTSquare Uses Domin Servo Valves in Testing Drive Components

DTSquare is a company in Stuttgart, Germany that builds machines for testing how parts hold up under stress. Working with a university in Karlsruhe, they created a project to evaluate how drive components function when subjected to complex forces.

Domin hydraulic servo valves were incorporated as well as a custom hydraulic cylinder, co-designed with Hänchen. The cylinders provided axial and lateral movement via a flange extension. Axial motion was driven by a shaker through the motor shaft, while lateral forces were applied using hydraulic cylinders with Domin servo valves.

Testing Requirements and Metrics

The servo valves used in the testing application were Domin’s S6 Pro. Highlights of their performance in this setup included:

“We are very satisfied with Domin’s valves. They are very robust, and phase-match is excellent even at high frequencies.”

Frank Deuble

CEO & R&D Manager, DTSquare GmBh

Hense Actuators Used in Moment & Torsion Testing of Truck Axles

In moment testing of truck axles, servo-hydraulic rotary vane actuators apply controlled torque to the axle to test failure. The actuator does not drive the axle in continuous rotation but loads it incrementally to determine its breaking point.

By design, vane actuators deliver a very high torque output. Adding vanes reduces the rotation range but multiplies torque, making them well suited for dynamic component, fatigue, durability, and failure testing needing high forces in driveline components and other materials.