HYDRAULIC CYLINDERS — SPECIALTY / TEST CYLINDERS

Hydraulic Cylinders — Specialty / Test Cylinders

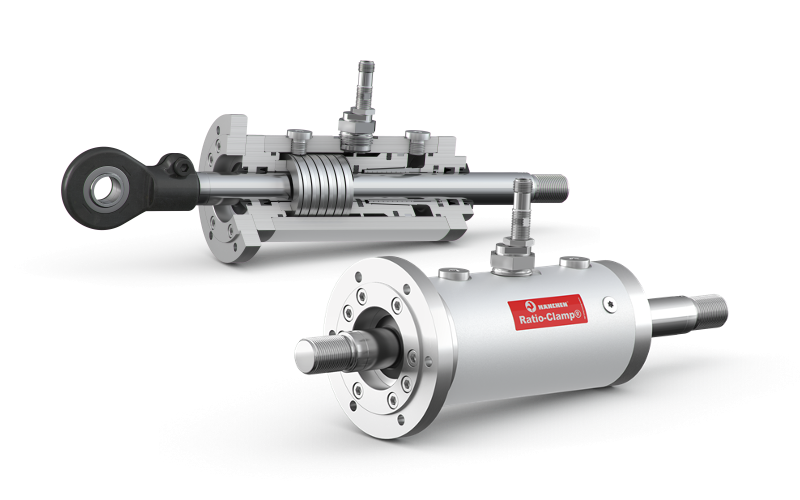

Specialty cylinders are offered by Hänchen. Hänchen has renown for top quality hydraulic cylinders for many years with one of the largest testing range in the market, offering lightweight servo actuators for static applications or high frequency cylinders for dynamic testing:

Advantages at a Glance:

Which series is right for my application?

Servo cylinders of the Series 120 and 300 are light-duty test actuators for simple testing tasks. For more challenging tasks, the Series 320 is a hydrostatic design offering excellent precision and high performance, allowing for high lateral forces and speeds.

General Specifications:

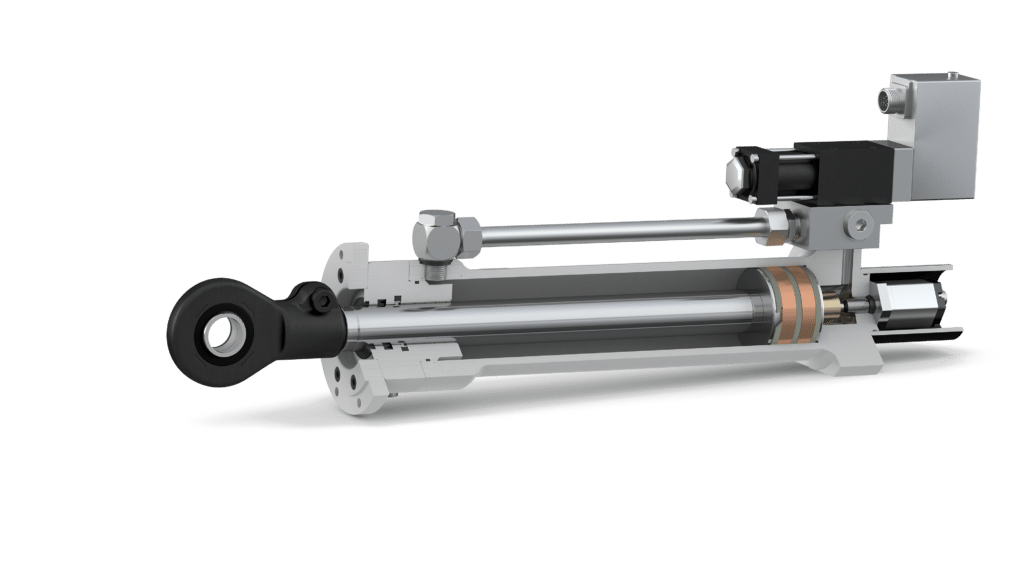

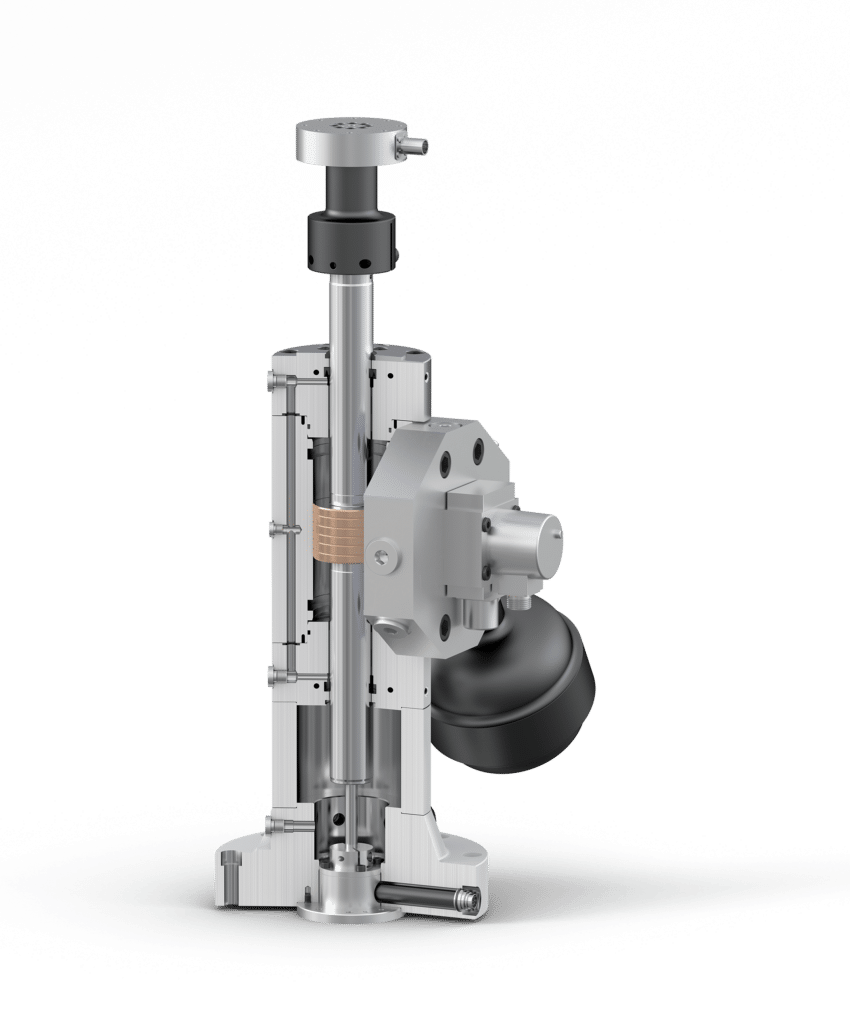

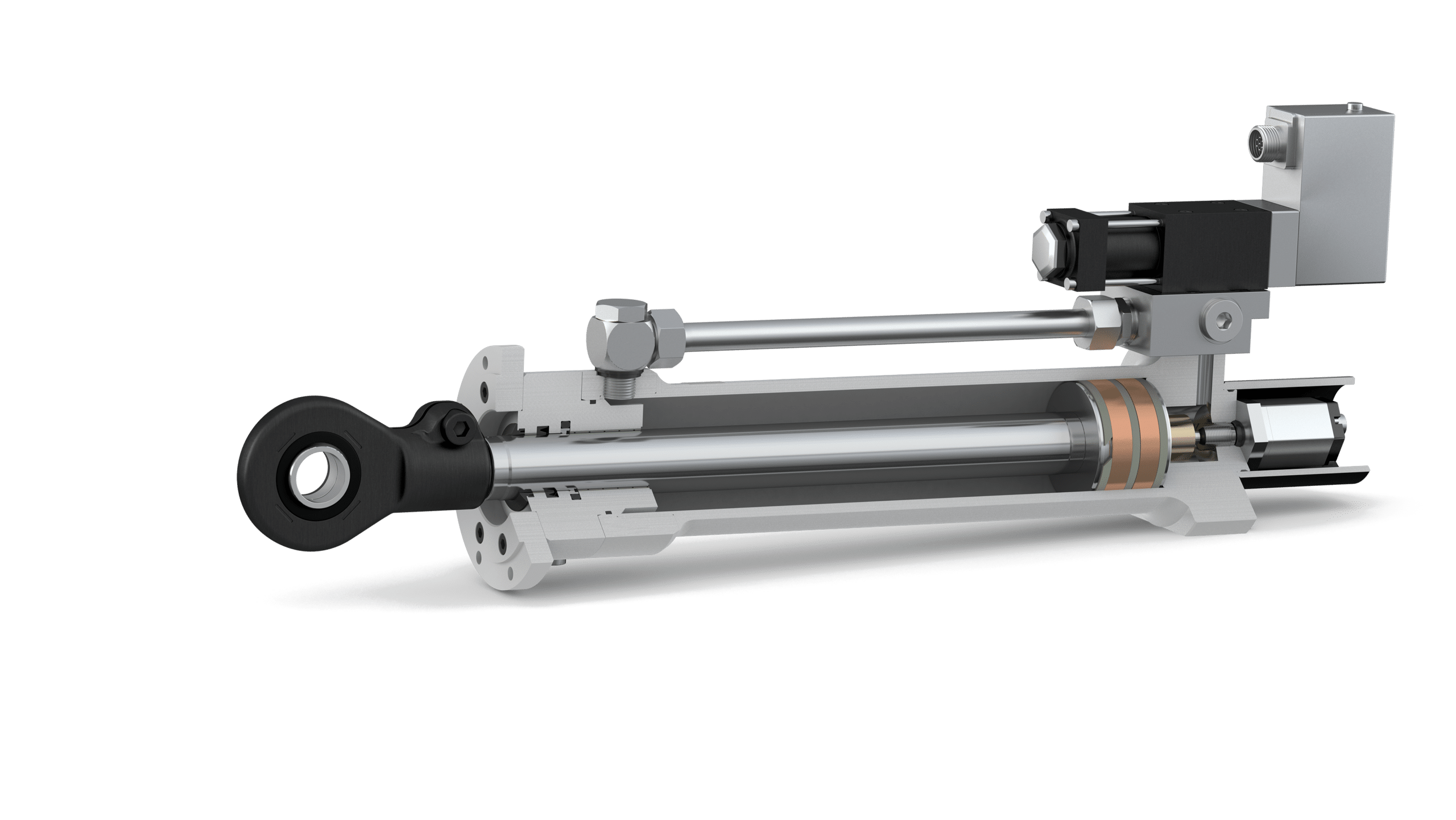

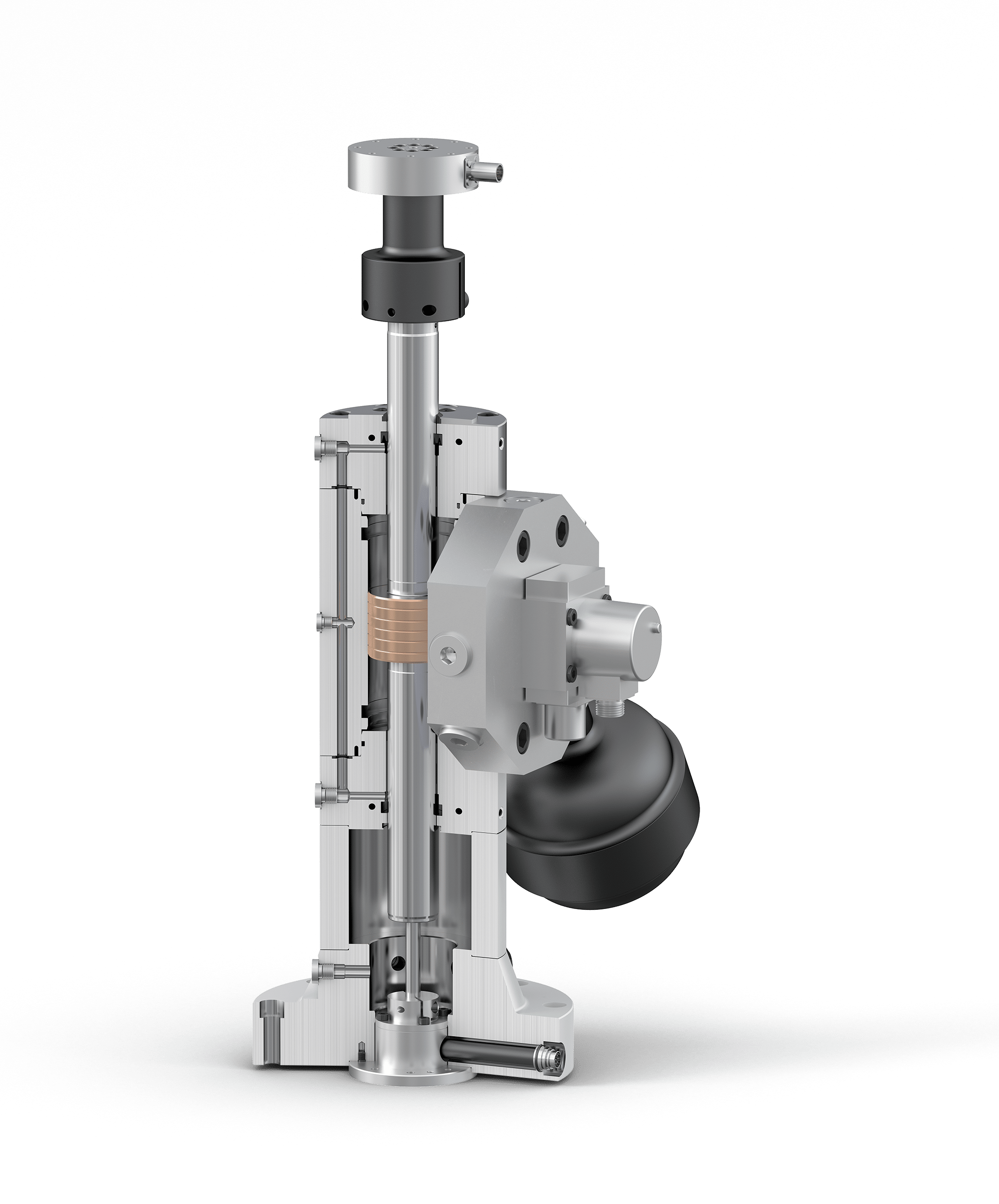

The 320 Series: Constructed for highly dynamic tests

Perfect for industrial applications, structure tests, and load simulations: the Series 320 test cylinder is the best choice for challenging tasks. It performs well, for example, in checking the functional safety of systems, component parts, or products; for structural testing of airplanes, refrigeration compressors, automobile exhaust system; or for simulating loads and movement, such as operational profiles and flight profiles.

The Series 320 is built from a solid block of steel. This means that any part of the cylinder can be customized to your requirements unlike standard models with limited sizing options. Rigid construction of the cylinder means means no leakage, a long service life, and good data.

4 Stand Out Features of the 320 Series:

Hänchen is a supplier and hydraulic cylinder manufacturer for various applications including construction, mechanical, technological, and industrial.

Stick-Slip in Hydraulic Cylinders

Our Hydrostatic Design

How are Test Cylinders Used?

Automotive

Servo hydraulic lifecycle tests are the current industry standard for automobile components that are used far beyond safety-related structural elements. Users can depend on hydraulic test actuators for high positioning accuracy and reliability in applications for test systems and real time control. A test cylinder with a dynamic lift of up to 35 mm (1.3 in.), speed of 1.3 m/s (51.2 in/s), and acceleration of up to 50 m/s (1968.5 in/s) could be used for a test load requiring up to 28 kN (6,294 lbf) and a frequency up to 20 Hz.

Aerospace

System tests that simulate loads and environmental conditions in different flight phases are particularly demanding. To test the landing flaps and slats, servo hydraulic cylinders could be used here to replicate the airflow that involves rapidly changing forces with irregular parameters. For example, a servo cylinder with a bore between 40 to 160 mm (1.5 to 6.2 in.) could be used for a test stand with a holding force between 140 – 300 kN (31.4 to 67.4 lbf) and a stroke requirement of 300 to 1,670 mm (11.8 to 65.7 in.).

Fluid Power

To determine the characteristic values of a seal, seal test benches are suitable for simulating a wide range of operating conditions. Double rod cylinders could be used here for fatigue tests focused on examining the frictional force of the seals, tightness on rods and shafts.

Choosing a Testing Cylinder

Dynamic Movement

First, determine if the cylinder will be used in highly dynamic applications, such as torque/torsion testing of axial loads and other drive line components. If so, seal protection is important to have, along with a servo valve that can be mounted to the actuator to offer more control to the device. It is important to know the application including the speed, pressure, loads, and any forces acting on the cylinder.

Frequency

What frequency will your cylinder require? Industrial applications and dynamic testing typically have higher frequency ranges, with some frequencies greater than 100 Hz.

Seals

It’s important to pay attention to the conditions your cylinder will be in. Conducting tests in conditions like salt spray fog, in climate chambers, or in a lab require individualized protection. Seal factors to pay attention to include temperature ranges, types of movement (simple, sensitive, controlled), outdoor stress, stick resistance, and type of medium, etc.

Load Holding

If loads need to be held in position for extended times, a rod lock can be included which allows a load to be held in a precise position and without power/pressure being applied.