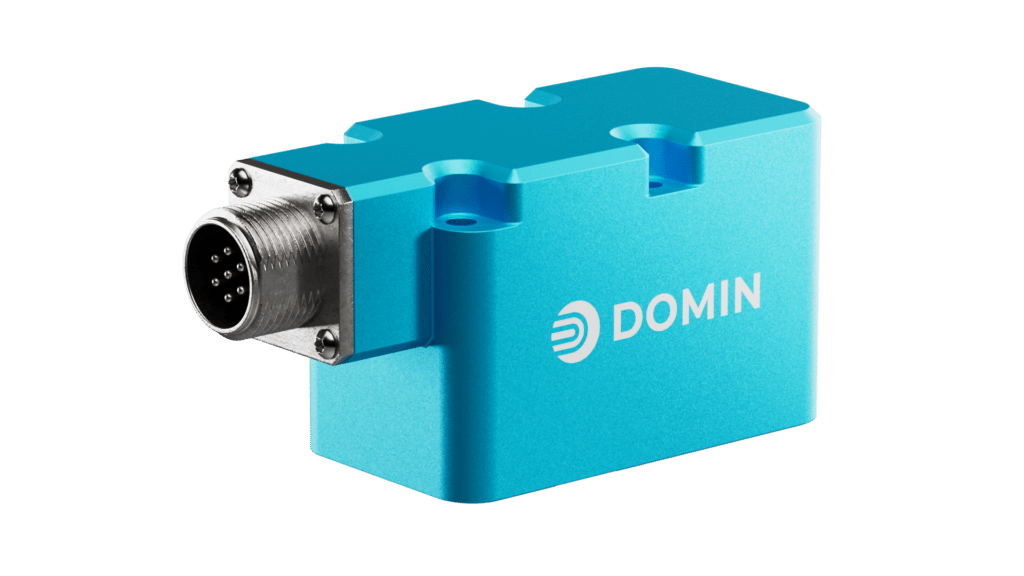

Hydraulic Servo Valves

Introducing a new generation of servo valves that deliver exceptional performance and precision, without compromise to cost, efficiency, and industrial reliability.

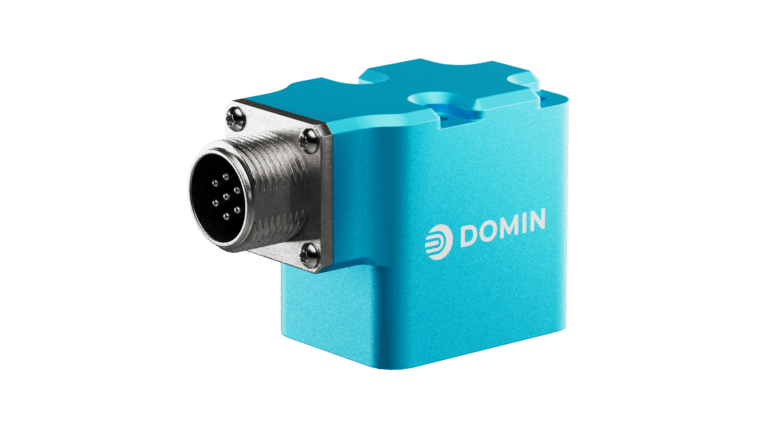

World’s smallest direct drive valve weighing less than 0.64 lbs (300 g), flow up to 5 gpm (18 lpm).

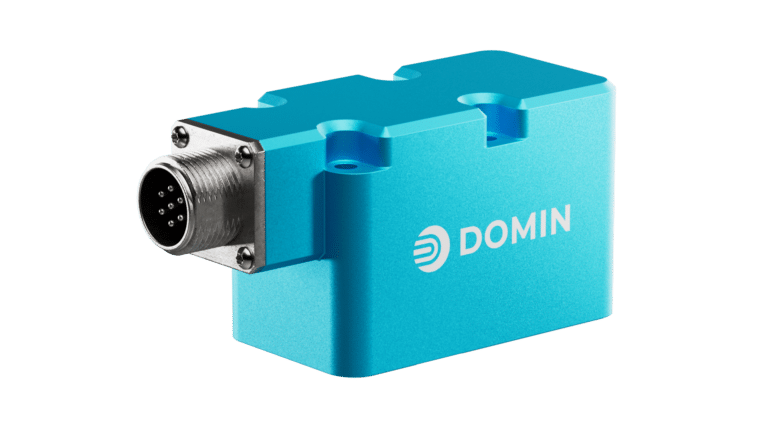

Ultimate power density weighing 1.21 lbs (550 g) with flow up to 16 gpm (60 lpm).

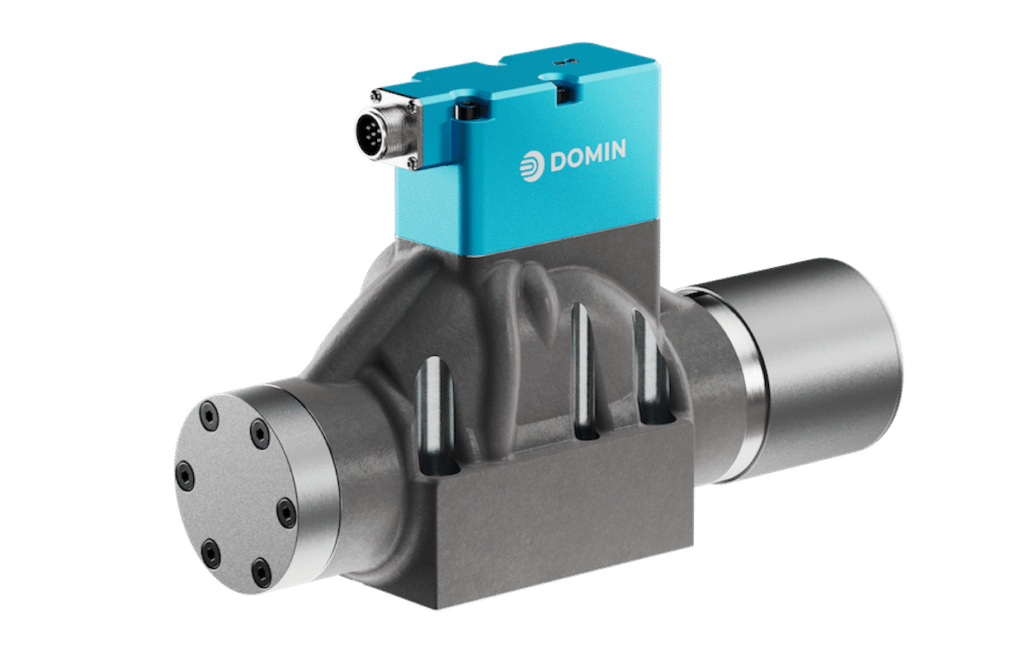

Most efficient direct drive valve for high flow applications from 13 to 66 gpm (50 to 250 lpm).

The next evolution in high-performance, high-flow valves from 66-174 gpm (250-660 lpm).

Need Support? We Can Help.

What Makes Us Different?

Setting new standards in performance

Patented additive manufacturing and compact electronics create new standards in power density, performance, and reliability.

Repeatable and reliable results

78% faster step response than traditional two stage valves with low hysteresis, null shift and threshold.

Major energy and emissions savings

$400 in annual energy savings per valve compared to a typical two stage valve.

What are Domin Valves?

Comparing Leading Valve Designs

Two-Stage Servo Valves

Two-stage servo valves, or mechanical feedback valves, are valued for their compact size and excellent dynamic performance, including fast response times and high-frequency capabilities. However, they come with limitations. The small orifices and high-pressure seals that help maintain performance can also make them more susceptible to contamination and blockages, especially if operated in harsh environments. Additionally, because they lack onboard electronics, they do not deliver the same level of repeatability and accuracy as modern direct drive valves.

Direct Drive Valves

Direct drive valves utilize an electrical feedback design. Contamination and hysteresis occur less frequently with direct drive valves making them more durable for demanding industrial applications. However, this comes with trade-offs in performance and size. Direct drive valves are generally heavier and bulkier in design, with slower step and frequency responses compared to two-step valves. This makes them less suitable for high-performance applications where dynamic response is critical.

Domin Valves

A Domin valve is a considered a servo proportional valve, a hybrid between two-stage servo valves and direct drive valves. Domin merges the benefits, such as the performance, efficiency, precision, and compact size from both without needing to compromise. Domin’s S6 Pro, for instance, offers an unmatched balance of performance and efficiency, boasting a 78% lighter design, a 67% faster response, 340% higher bandwidth, and 73% higher maximum flow compared to an equivalent direct drive valve.

How Domin’s Advanced Technologies Shape Performance

Modern Electronics

Slim, on-board electronics replace outdated bulky centralized systems. This improves control, data processing, and communication capabilities while reducing the overall size.

Modern Design and Simulation

Modern design and simulation technologies streamline development, enabling rapid iterations and faster decision-making and production processes.

Magnetic, Hall Effect Sensors

Hall effect sensors provide a more efficient and precise method of measuring position compared to traditional linear transducers. By utilizing magnetic fields, these sensors offer exceptional accuracy in both linear and rotary applications while significantly reducing size and weight.

Advanced Motors

Domin valves are equipped with brushless DC motors, offering superior precision and efficiency over traditional solenoids and limited-angle torque motors. These motors provide consistent performance without the wear issues associated with brushes, leading to longer life and reduced maintenance.

Metal 3D Printing

This patented manufacturing process surpasses the limitations of subtractive machining, allowing the creation of lightweight structures through optimized material distribution and the removal of excess material.

Product Benefits

Exceptional Precision and Accuracy

Cost Savings and Efficiency

Reliability and Durability

How to Select a Domin Valve

1. Select valve model for application

First, choose the appropriate valve for your application. Domin valves have been designed to accommodate a wide range of flow rates and pressure conditions. The options include:

2. Determine rated flow

Next choose rated flow. Flow range is between 0.2 to 66 gpm (0.5 to 250 lpm), all rated at a 1,015 psi (70 bar) pressure drop. For systems requiring high precision control, the rated flow can be tuned to the nearest decimal point within the range for near-exact performance.

3. Choose spool lap condition

The spool lap condition determines how the valve reacts to control inputs.

Standard spool lap conditions:

4. Select control method

Domin valves feature electrical feedback and onboard electronics to simplify integration into modern hydraulic systems. All that is needed is a 24V power supply and a standard input/output interface. The control method options allow for seamless integration with various control architectures, ensuring that the valve response precisely to electrical signals.

Control method options:

5. Choose electrical connector

Next, select the right connector. Industry-standard connectors are provided to ensure easy compatibility and simple integration with your existing infrastructure.

Common connector options:

6. Does your system require an enable mode?

For systems requiring an enable mode, typically a simple yes or no option, these can be easily configured into the Domin valve.

This feature allows operators to control when the valve is active, improving both safety and flexibility.

7. Select fluid type

Domin valves operate with standard red oil, as it is the most common fluid type found in hydraulic systems. Custom solutions are available for specialized fluid requirements.

8. Choose seal material

Selecting the right seal material ensures that the valve operates properly, even in harsh and challenging environments.

Seal options: