Eckart Rotary Actuators

More than 70% of Eckart actuators are custom-designed to meet specific customer needs. Tell us about your project and we will present you with an optimum solution.

With decades of experience, Eckart can design and build a quality rotary actuator to your specifications.

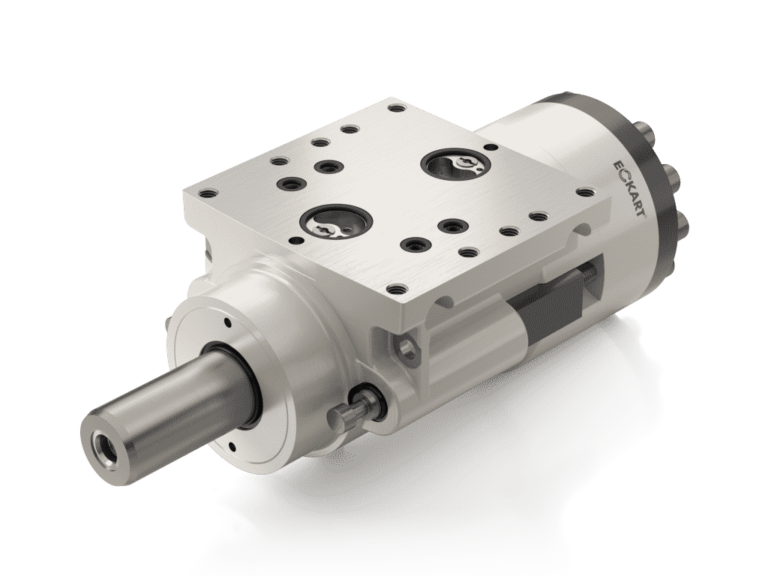

The SM4 rotary actuator with an operating pressure of up to 250 bar offers rotary movement with a compact footprint.

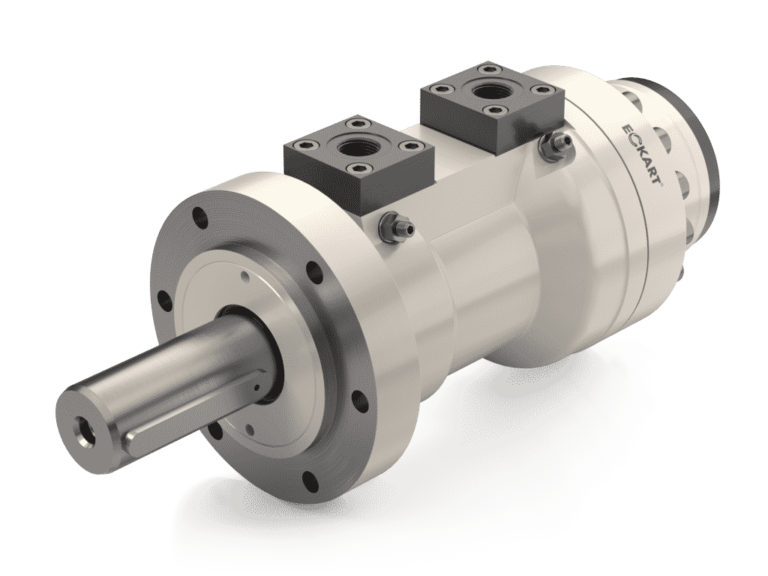

The E3 with a maximum operating pressure of 210 bar, is designed for, but not limited to, mobile applications where a flange shaft is desirable.

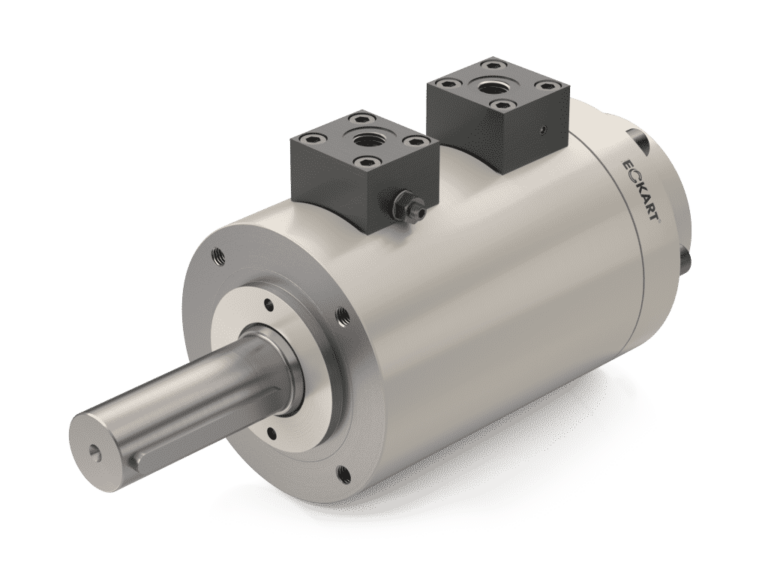

The E1 rotary actuator with an operating pressure of up to 100 bar offers rotary movement with a compact footprint.

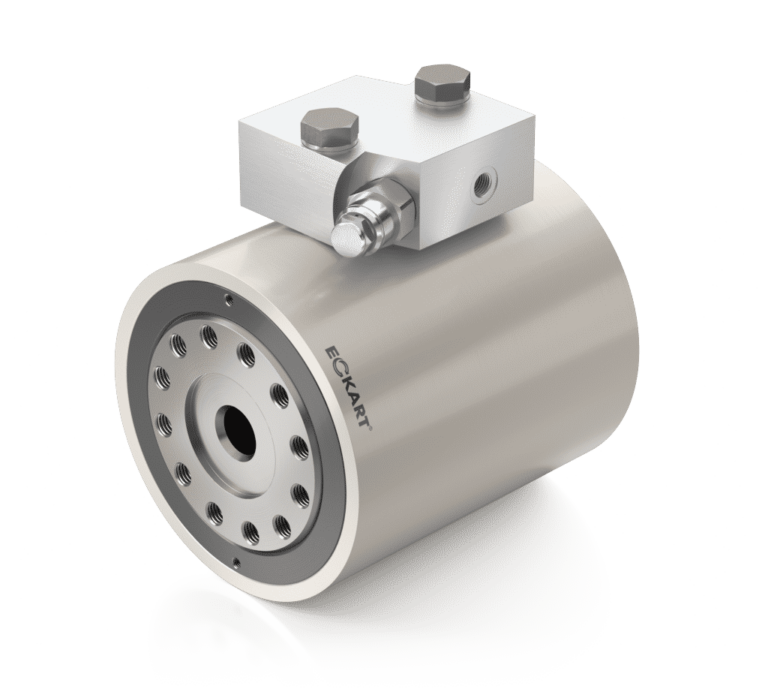

The HyRAV® valve actuator is tailored perfectly to your needs. HyRAV by Eckart, comprises a full series of double-acting or spring return actuators.

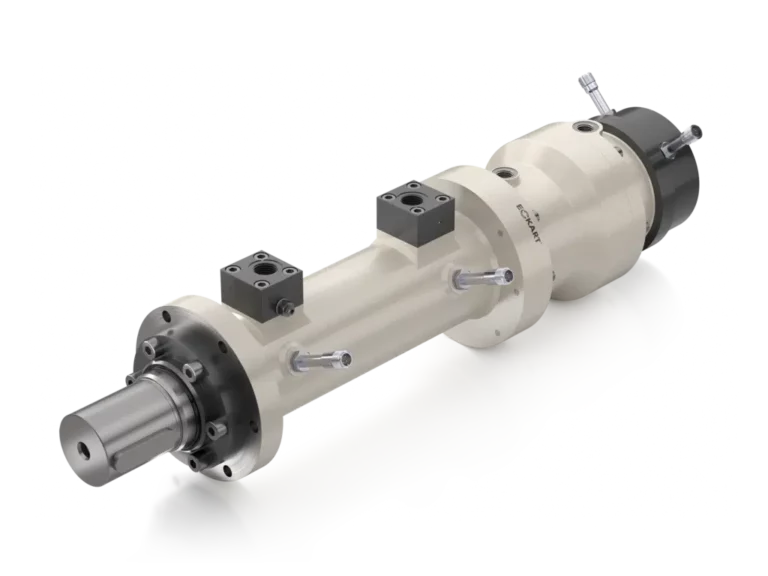

The HSE4 rotary-linear actuator combines an independently controllable dual acting cylinder with a rotary actuator.

The PSM2 pneumatic rotary actuator is most suited to applications in small installation spaces with low weight specs.

The Eckart PHSE pneumatic rotary-linear actuator is a combination of a rotary actuator and a dual-action linear cylinder.

Need Support? We Can Help.

What Makes Us Different?

Customized Solutions

Specific applications call for specific actuators. Customize the amount of rotation, choose the material, opt for special protective coating, add sensors, and more.

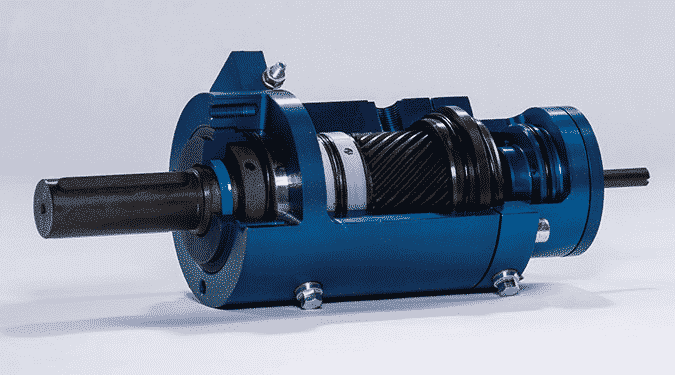

Helical Spline Design

Helical gear rotary actuators are designed with space in mind and are suitable for many applications needing a compact solution.

High Torque & Precision

Dependable and durable actuators with high torque and precision, often custom-designed to meet specific needs.

How to Choose an Eckart Rotary Actuator

1. Main Specifications

It is important to know your basic requirements for torque, rotation, and pressure.

Depending on your specifications, multiple actuator models may fit your needs. Refer to the chart below to explore potential options. We will discuss additional options to help determine the best fit for your application.

| Model | Torque | Rotation | Pressure |

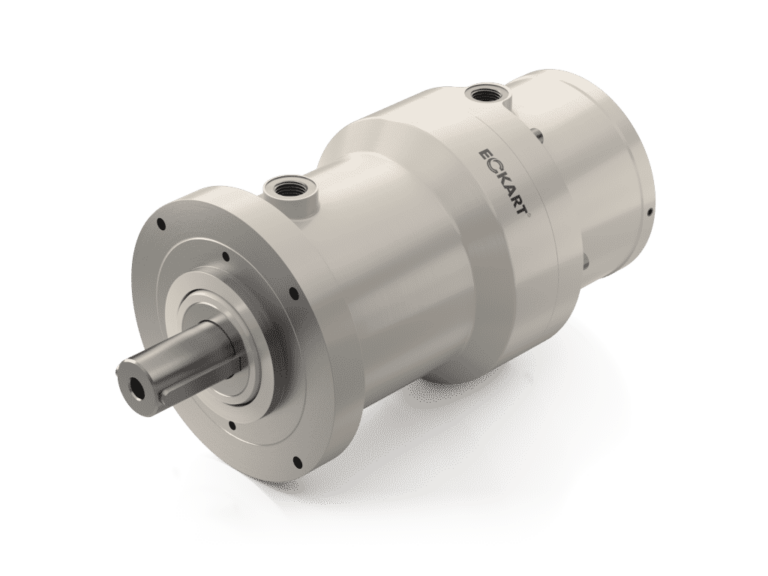

| E3 | 50 to 3600 Nm (440 – 31,860 in-lb) | 180, 360° | Up to 210 bar (3,045 psi) |

| E1 | 74 to 2450 Nm (650 – 21,680 in-lb) | 90°, 180°, 270°, 360°, custom | Up to 100 bar (1,450 psi) |

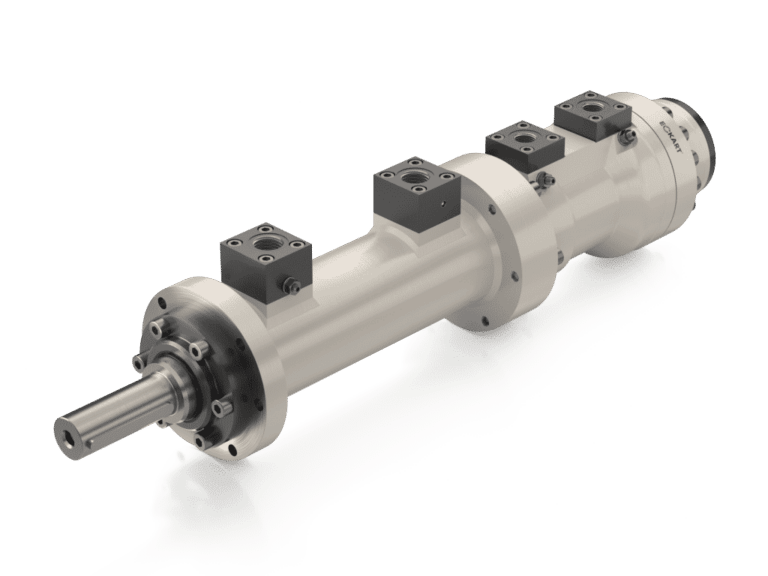

| SM4 | 180 to 250,000 Nm (1,590 – 2,212,686 in-lb) | 90°, 180°, 270°, 360°, custom | Up to 250 bar (3,625 psi) |

2. What is the application for?

Next, a few factors can help decide which model is right for your application:

If neither of the questions apply, then the SM4 model is recommended as a starting model.

Refer to the chart below to help guide your selection:

| Best for | |

| SM4 Most Popular | Full customization, heavy-duty, high force applications. See custom options here. |

| E1 | Full customization, low pressure, lightweight applications. Higher torque at the same pressure ratings than the SM4. |

| E3 | Most compact, direct attachment to load (flange shaft) |

Eckart Rotary Actuator Models

After determining the important factors above, we can help you find an actuator design to best fit your application from our Eckart line. Eckart is the leading technological innovator in developing custom-made rotary actuators and valve actuators based on helical gear technology.

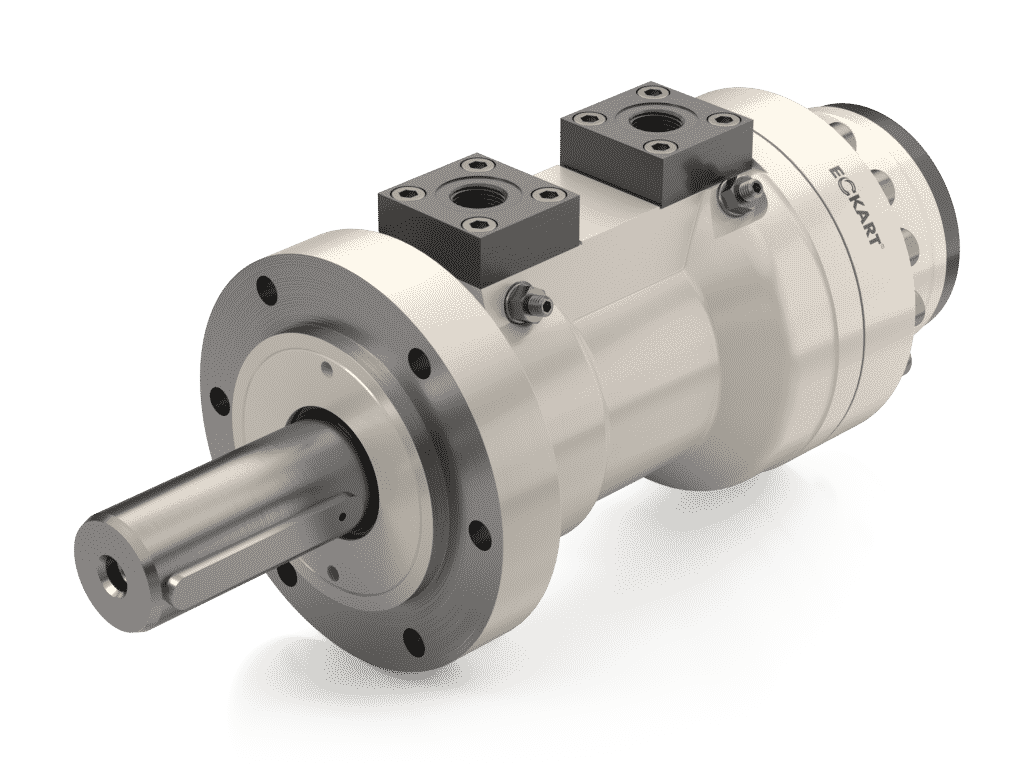

SM4

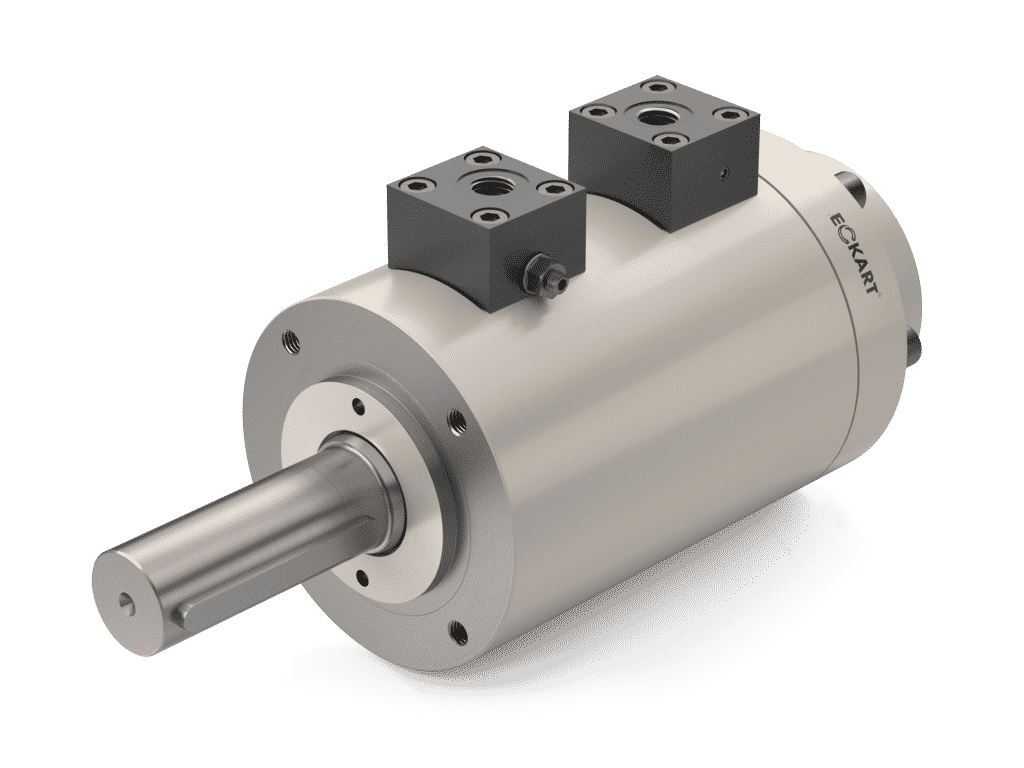

E3

E1

SM4 Rotary Actuator

Our SM4 rotary actuator is a heavy-duty and highly-customizable rotary actuator designed for the toughest and most-demanding applications with an operating pressure rating at 3,625 psi (250 bar) and maximum toques up to 2,200,000 Ibs-in (250,000 Nm).

E3 Rotary Actuator

For mobile applications where a flange shaft, cantilever mounting style is desirable, our E3 rotary actuator is an appropriate choice. It has a maximum operating pressure of 3,046 psi (210 bar) and is available with torques up to 31,800 Ibs-in (3,600 Nm).

HSE4 Rotary-Linear-Actuator

Our HSE4 rotary-linear-actuator is a combination of a rotary actuator and a dual-action linear cylinder and is commonly used for applications that require lifting and turning. It has an operating pressure of 1,450 psi (100 bar).

E1 Rotary Actuator

The E1 rotary actuator is the latest rotary actuator in our product line and was designed for low-pressure hydraulic systems with typical operating pressure ratings of up to 1,450 psi (100 bar) and is available in torques up to 22,000 Ibs-in (2,500 Nm).

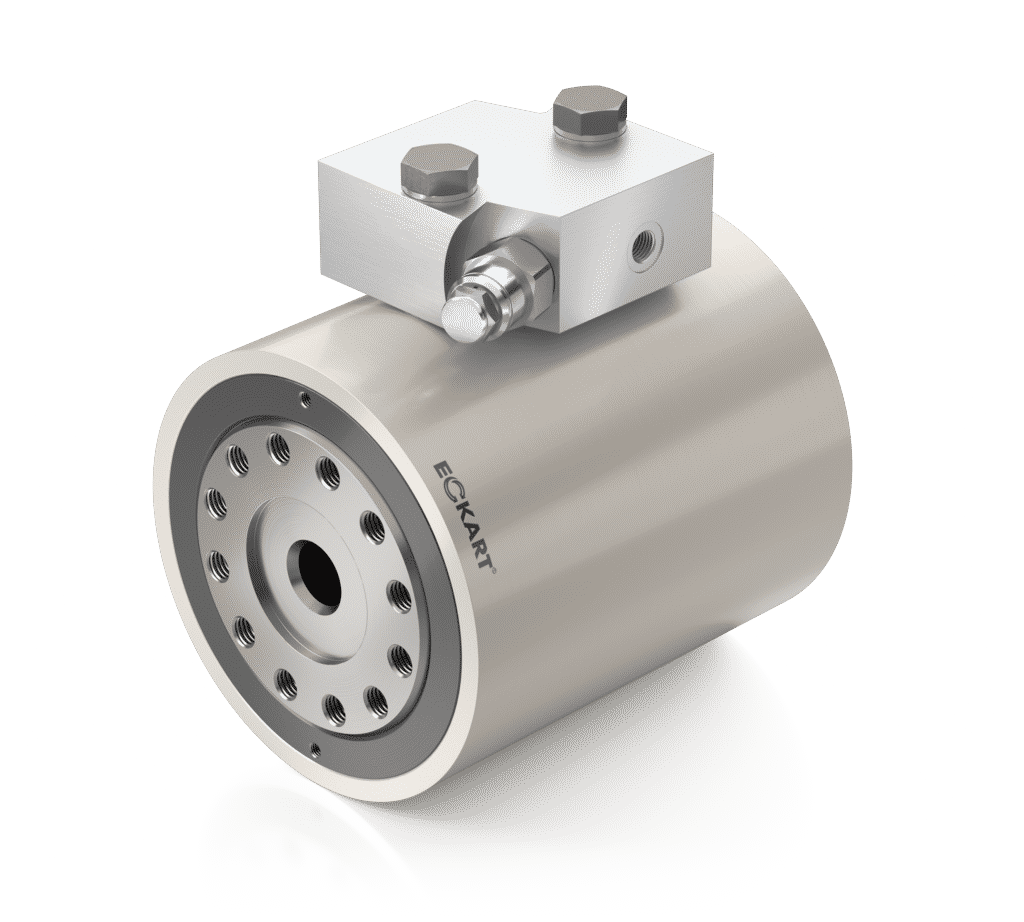

HyRav Rotary Valve Actuator

The HyRAV quarter-turn valve actuators have 12 drive sizes with torques up to 2,200,000 Ibs-in (250,000 Nm) and an operating pressure up to 3,046 psi (210 bar).

Custom Rotary Actuators

More than 70% of our actuator line was custom-designed to meet specific customer needs. Contact a specialist and get your customized, optimum solution.

Eckart Rotary Actuator Benefits

Adjustable drive shaft datum

The adjustable drive shaft datum allows you to easily reset the starting position if there’s a machining error or alignment is lost during maintenance. By loosening the gear ring between the housing and actuator rear, the drive shaft can be rotated to the desired position and securely locked in place. This is especially useful after servicing tasks like seal replacements or internal inspections, where disassembly may cause gear alignment to shift. (Not available on E3).

Externally adjustable end stop

The externally adjustable end stop makes installation more forgiving by letting you correct for small mounting errors, ensuring the actuator achieves the precise angle needed.

If you drill or tap the mounting holes with a slight deviation, the actuator might not rotate its full range. For example, a 90° actuator may only achieve 85°. This is solved with the adjustable end stop, which corrects ±5° of misalignment in either direction. (Not available on E3), (Standard SM4, optional E1).

Wear-resistant protection and moving parts

All surfaces are specially treated with a gas nitro carburized and oxidized process at temperatures between 400-600°C, resulting in a compound layer that provides significant resistance to wear and corrosion. The actuator has excellent sliding characteristics due to the precise machining of the helical teeth. These two technologies work together to ensure a long service life.

Highly perfected end cushioning

Optional end cushioning ensures reliable slowing to stop for nearly any application. Proportional or servo controls could be omitted, depending on the application, through reliable mechanical cushioning. The cushioning curve is highly customizable and can be finely tuned by utilizing up to 10 individual orifices plus throttling valves. (Not available on E3).