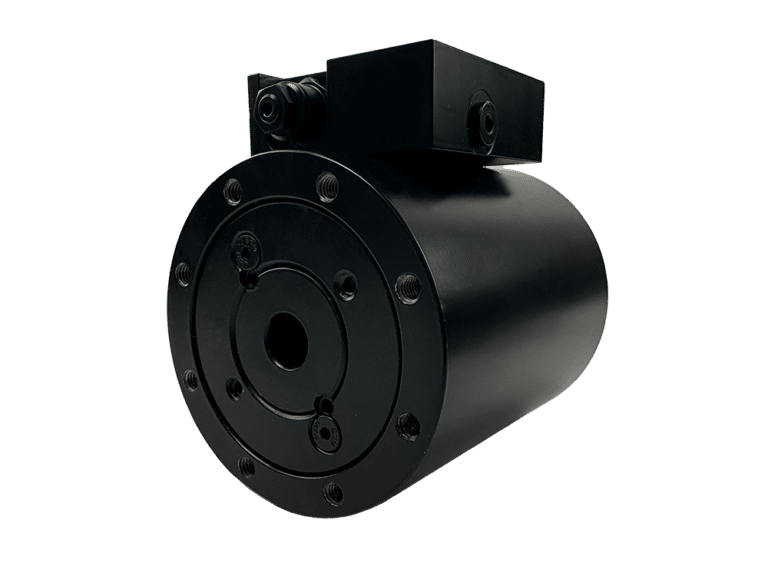

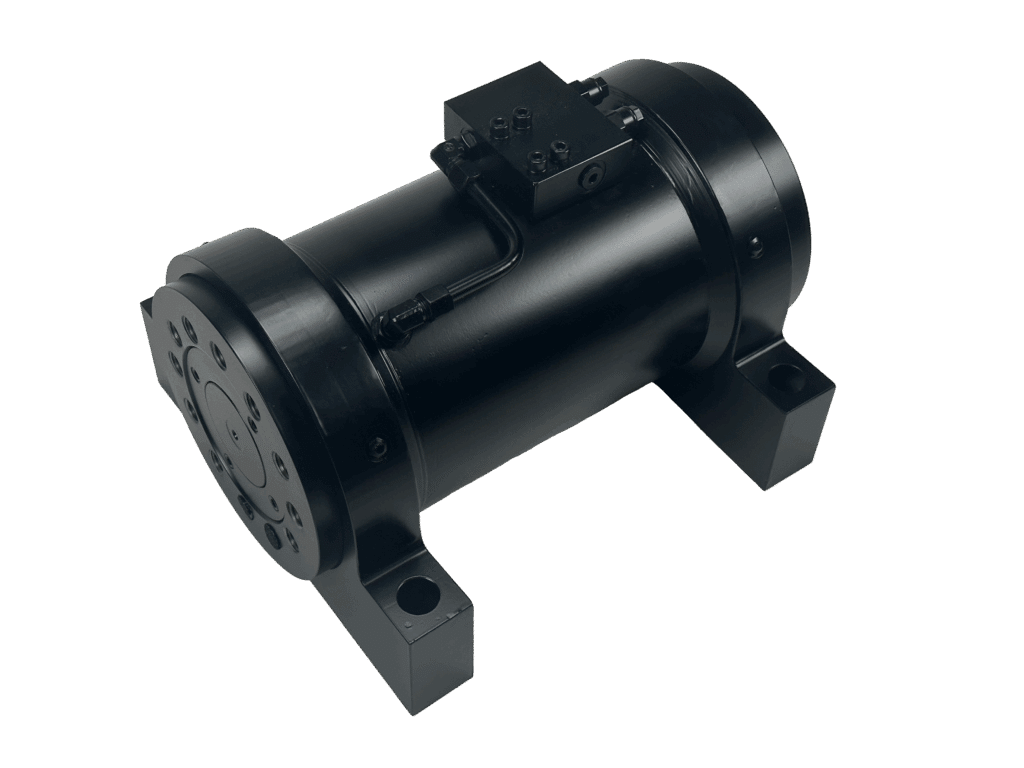

IC Series Rotary Actuators

Drop-in replacements for Helac rotary actuators. Lead times as fast as 20-26 weeks (or 10-14 weeks with optional expedited shipping).

Optional load holding valves for intermediate position holding and over center conditions.

Need Support? We Can Help.

How to Choose an IC Series Rotary Actuator?

There are 4 standard models in the IC Series. Use the chart below to find the best fit based on the desired torque, rotation, and mounting requirements.

| Specifications | IC10 Series | IC20 Series | IC30 Series | IC40 Series |

|---|---|---|---|---|

| Rotation | 180°, 360° | 180° | 180°, 360° | 200°, 220° |

| Max Drive Torque in-lbs at 3,045 psi (NM at 210 bar) | 1,590 – 23,890 (180 – 2,700) | 4,420 – 37,170 (500 – 4,200) | 16,180 – 212,410 (1,900 – 24,000) | 24,780 – 59,290 (2,800 – 6,700) |

| Max Holding Torque in-lbs (NM) | 5,570 – 83,190 (630 – 9,400) | 11,500 – 92,930 (1,300 – 10,500) | 43,360 – 522,190 (4,900 – 59,000) | 53,980 – 126,560 (6,100 – 14,300) |

| Mounting, Body | Flange | Foot | Foot, Flange | Foot |

| Mounting, Shaft | Cantilever | Cantilever, Straddle | Cantilever, Straddle | Straddle |

What Makes Us Different?

Helical Spline Design

Helical gear actuators are designed with space in mind for low maintenance and backlash in a compact package.

Drop-In Replacements

Replace your rotary actuator for leading brands, such as Helac, SJH, and HKS.

Fast Lead Times

Flexibility as a small business enables fast lead times as quick as 10 weeks depending on model and shipping method.

Application Examples and Solutions

Each of our IC Series models fit a wide variety of applications and provide a large number of solutions across different industries such as waste management, forestry, mining, construction, and more.

Tree Care Handling in Forestry (IC10)

Rotary actuators are typically used in forest and felling equipment to move components, such as grapplers or boom arms, in tree removal and timber harvesting applications.

Spreaders in Agriculture (IC20)

Helical gear actuators create rotational movement and control for just about any farm machinery, from folding attachments for on-road transportation to positioning the nozzle of a mobile sprayer in place.

Drill Rigs in Mining (IC30)

The actuator manipulates the drill arm and has a 360° rotation, enabling a full range of movement where the drill arm might need to create blast holes from the ground to the ceiling.

Bin Tippers in Waste Management (IC40)

In the refuse/waste and recycling tipper market, standard degrees of rotation for tippers include 135° or 180°. The IC40 Series, however, offers rotations of 200° and 220°, adding more extension to the tipper to dump the components of the waste receptacle entirely.

Are You Using Helac?

The IC Series is interchangeable for leading brands, such as Helac, SJH, and HKS. This series offers a cost-effective solution with fast lead times of 20-26 weeks or 10-14 weeks with optional expedited shipping if the model is not in stock. If you know your Helac part number, easily find the correct drop-in IC Series below by inputting your current Helac part number into equivalent part finder below.

Find My Part Number

Enter your Helac part number in the sections separated by dashes.

Need a Replacement Now? Ship by Airfreight

IC-Fluid Power has cultivated strong relationships in Asia and Europe, allowing us to streamline the shipping process. If your case is urgent, we will partner with our manufacturers to get the actuator delivered as fast as possible. The chart below shows the difference in shipment times between sea freight and air freight.

| Sea Freight (min 1,000 lbs) | Air Freight | |

| Manufacturing | 8-12 weeks | 8-12 weeks |

| Shipping Time | 12-14 weeks | 2 weeks |

| Total Delivery Time | 20-26 weeks | 10-14 weeks |