Rotary Actuators — IC20 Series

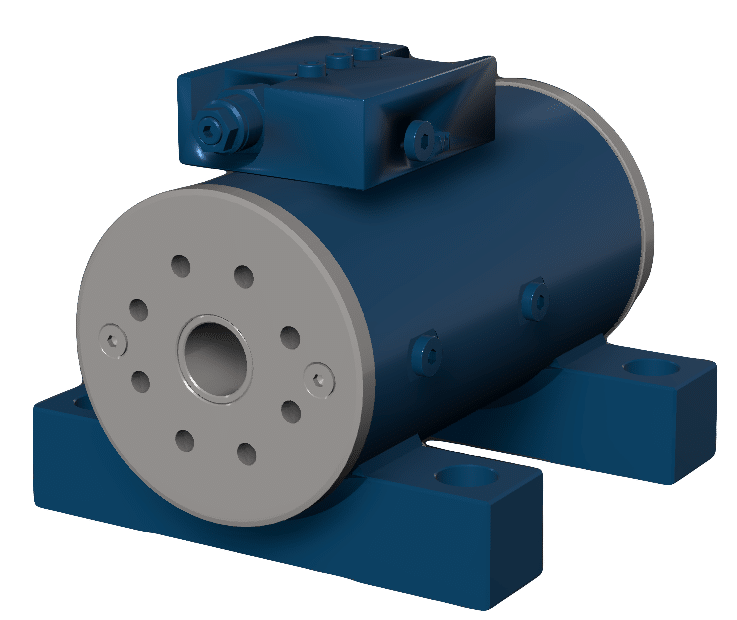

Foot mount to single or double flange, cantilever or straddle mount

Rotary Actuators – IC20 Series

The IC20 series has a max drive torque of 4,420 – 37,170 in-lbs at 3,045 psi (500 – 4,200 Nm at 210 bar). Given its high bearings and precision accuracy, it is a solution for many applications that involve positioning, rotating devices, steering, and more. Additionally, the IC Series was designed with high shock absorption to preserve the product’s life. It is also suitable for rotating applications where a standard rotation of 180° is needed. Foot mount to single or double flange, cantilever or straddle mount.

Hydraulic Rotary-Linear Actuator Standard Features:

| Model | 5 | 9 | 16 | 27 | 42 |

|---|---|---|---|---|---|

| Drive Torque in-lbs (Nm) | 4,420 (500) | 7,960 (900) | 14,160 (1,600) | 23,710 (2,680) | 37,170 (4,200) |

| Holding Torque in-lbs (Nm) | 11,500 (1,300) | 21,240 (2,400) | 38,940 (4,400) | 62,840 (7,100) | 92,930 (10,500) |

| Max Straddle Moment * in-lbs (Nm) | 22,120 (2,500) | 39,820 (4,500) | 90,270 (10,200) | 145,150 (16,400) | 279,680 (31,600) |

| Max Cantilever Moment * in-lbs (Nm) | 12,030 (1,360) | 21,940 (2,480) | 47,970 (5,420) | 100,010 (11,300) | 139,840 (15,800) |

| Radial Capacity lbs (kg) | 3,040 (1,380) | 4,690 (2,130) | 9,230 (4,190) | 12,300 (5,580) | 21,010 (9,530) |

| Axial Capacity lbs (kg) | 1,100 (500) | 1,490 (680) | 2,200 (1,000) | 3,080 (1,400) | 3,900 (1,770) |

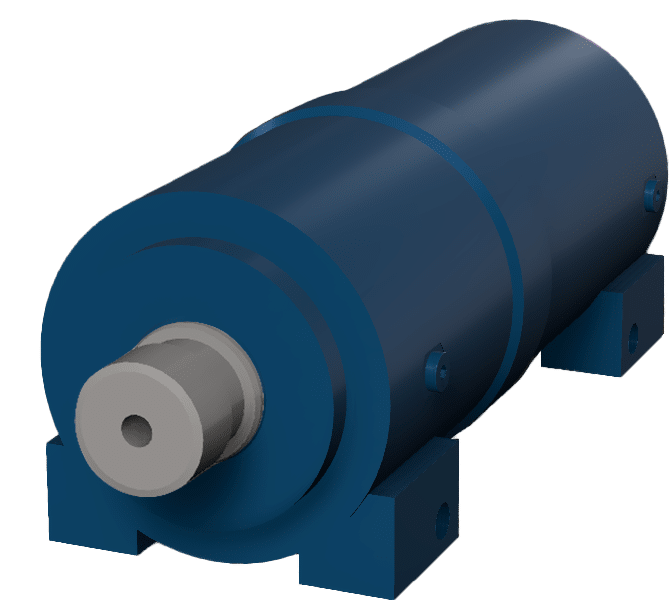

Cantilever Mounting

The load is securely bolted to the shaft flange. Cantilever mounting is ideal for loads needing support at only one end of the shaft, and is not advised for aerial work platforms or other critical safety-related applications.

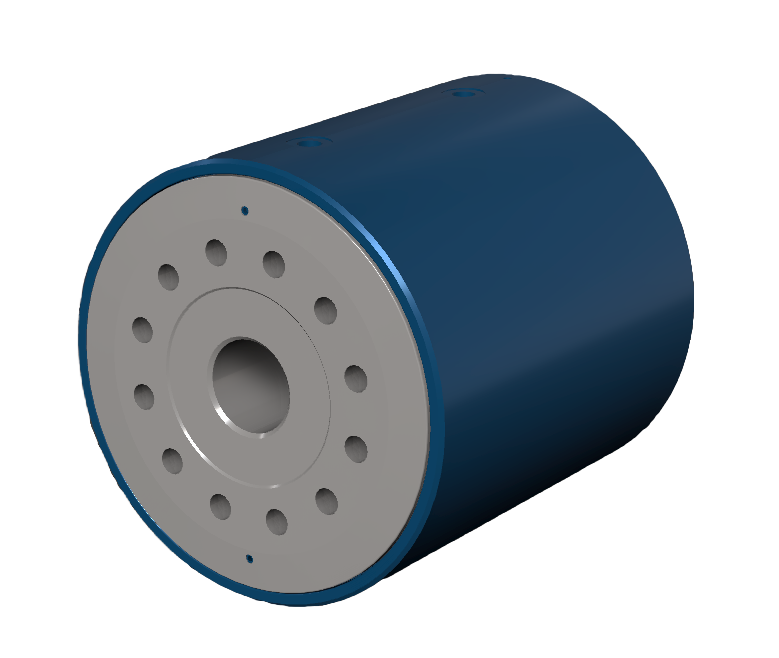

Straddle Mounting

Straddle mounting is ideal for loads needing support at both ends of the shaft. Similar to cantilever mounting, the top of the load is bolted to the shaft flange. The bottom can be secured by a tie rod passed through the shaft bore (IC20 Series only) or bolted to the end cap flange.

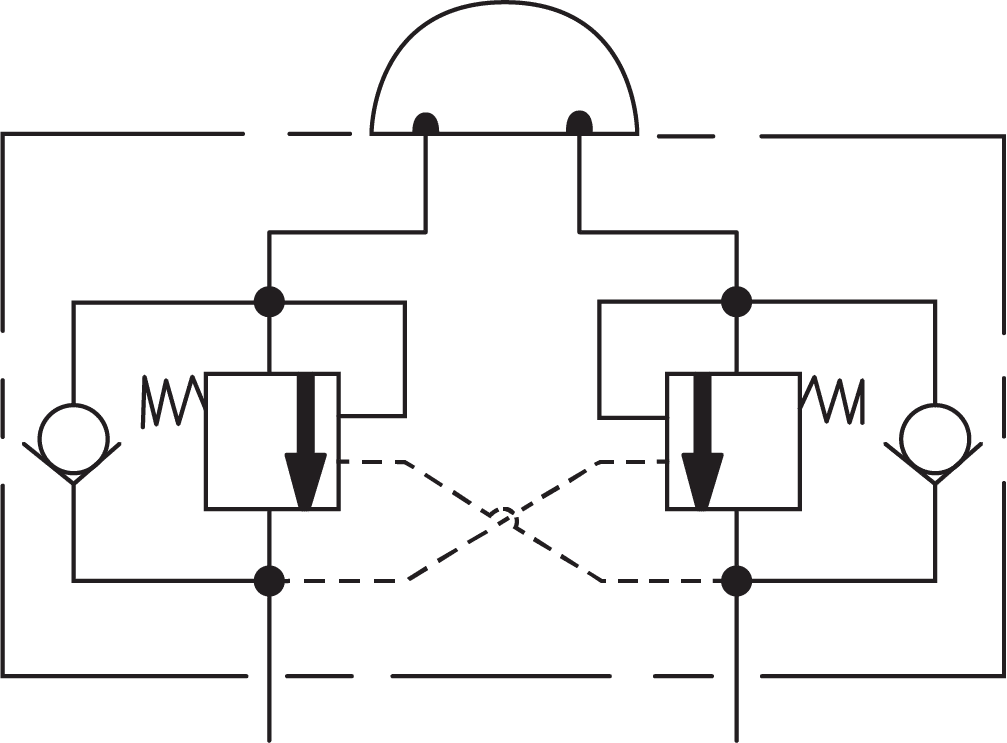

Counterbalance Valve

Actuators can be configured with a counterbalance, or load holding valve, to provide load stability and prevent the actuator from reaching excessive torque outputs. Producing back pressure in a hydraulic line gives control over the suspended load to stop unintended motion of the actuator. Valve blocks are available in steel and aluminum, and may be purchased separately if required at a later time.

Helical Spline Hydraulic Rotary Actuators

Our rotary actuators are the helical spline design. This means, a piston and a helix, or sliding spline, work together to convert the linear motion of the piston into rotational motion. Composed of two moving parts and some form of housing, the sliding helical splined gear concept within the actuator is used in many applications where a rotary movement is required. Helical Spline Actuators function when the piston is axially displaced using hydraulic pressure causing simultaneous rotation of the piston. Standard amounts of rotation is 180°. The primary benefit to this type product compared to alternative designs such as linkages using hydraulic cylinders (linear actuators) is its compact design.

Code Guide:

| 1 | Series | IC20 Series |

|---|---|---|

| 2 | Torque (output Torque/100) in Nm | 5, 9, 16, 27, 72 |

| 3 | Angle (other angles available) | 180° |

| 4 | Output | Q front flange S double flange |

| 5 | Mount | D foot flange M straddle |

| 6 | Counterbalance Valve | Y with valve W without valve |

| 7 | Thread Pattern | BLANK metric E imperial |

IC-Fluid Power, Inc. supports many applications including energy, marine & offshore, mining, packaging, plastic & injection molding, and more.