Pressure Intensifiers vs Gear Pumps, Rotary Actuator Main Benefits, and more…

November 13, 2025

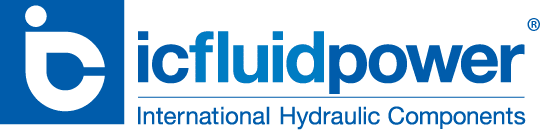

Pressure Intensifiers vs. Gear Pumps

Where Rotary Actuators Make a Difference

Choosing a Domin Servo Valve

When to use pressure intensifiers vs. upgrading to a larger pump

There are several ways to increase pressure in a hydraulic system. The most common is upgrading to a larger pump, but in some cases, a pressure intensifier is the better choice. Knowing when to use each method can make a big difference in time, cost, and efficiency.

Pressure intensifiers for targeted high pressure

Many hydraulic systems perform multiple functions, but not all require the same pressure. Imagine a machine with a dozen circuits but only one needs 5,000 psi. Instead of upgrading to a 5,000 psi-rated pump and replacing every component in your system to match that high pressure, you can simply add a pressure intensifier to the necessary circuit. With an intensifier, standard components can be used (typically 3,000 psi) while achieving high pressure only when and where it’s needed.

In car manufacturing, for example, pressure intensifiers are often used to help shape exhaust pipes. The main hydraulic pump provides about 80–90% of the pressure, while the intensifier delivers an extra boost, the “oomph” needed to bend the pipe into a fixed angle.

The main benefit here is that the HPU doesn’t need to be completely redesigned to achieve this outcome because pressure intensifiers are installed directly inline into your system, resulting in significant savings and time.

Pumps for high pressure in multiple components and simultaneous speed and force

A bigger, high-output pump is the preferred solution when your hydraulic system must deliver high pressure and high flow at the same time, continuously.

For example, agricultural applications such as cutting, clamping, or grabbing require high pressure and fast response. While a pressure intensifier can increase pressure, it does not supply the additional flow and may slow down the cycle time. In this case, upgrading the pump to meet your pressure and flow requirements would be the most efficient and cost-effective solution long-term.

The bottom line…

Where rotary actuators make a difference

Helical spline actuators are used across almost every industry. In mining, actuators position drill rig nozzles to create blast holes in walls and ceilings. In forestry, they rotate grapples to maneuver big pieces of lumber. In waste and recycling, actuators help empty and unload tippers.

Main benefits

Hydraulic rotary actuators are an excellent choice for a range of applications due to three main benefits:

Common uses

Here are just a few ways that actuators can be customized to your application:

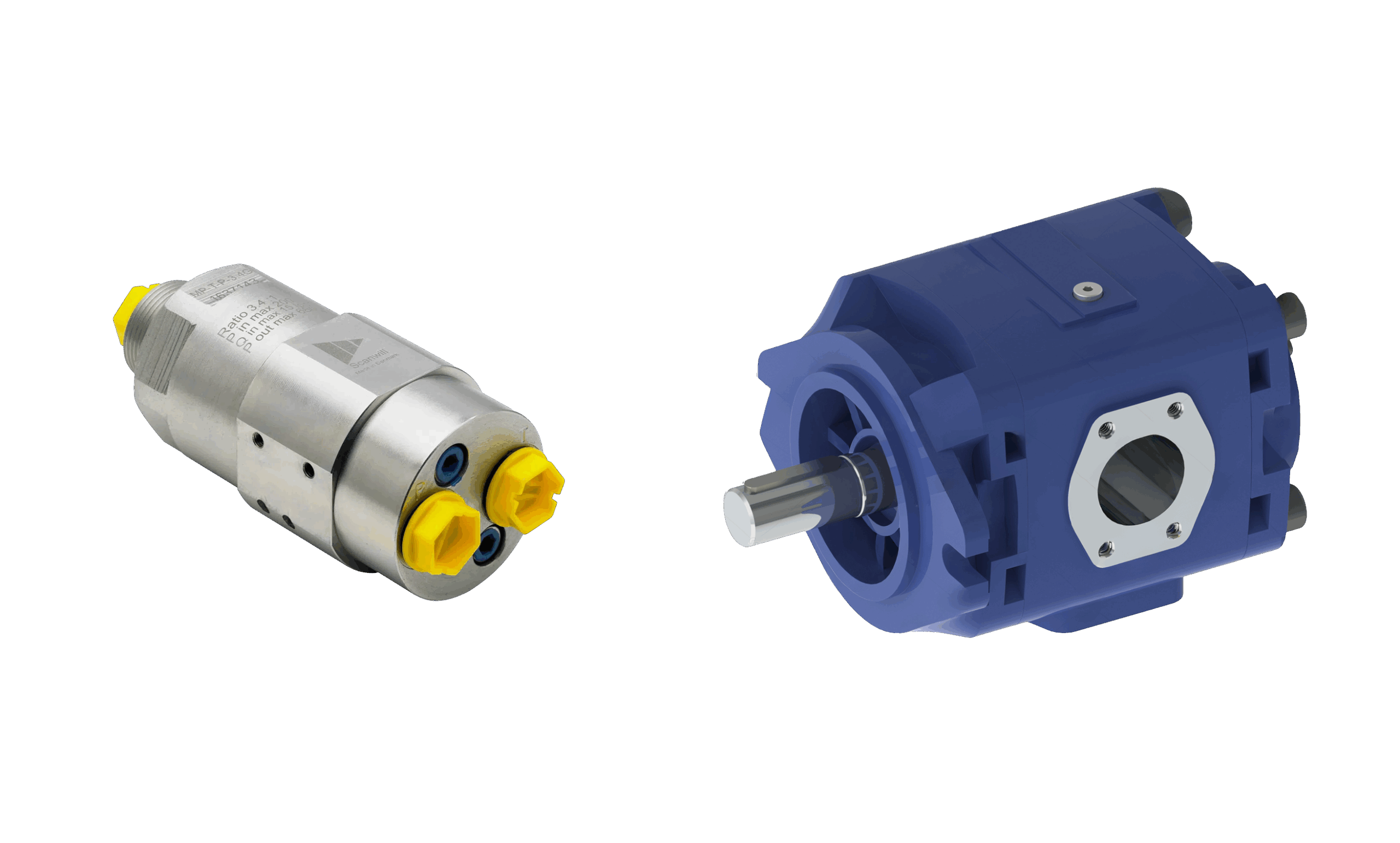

Choosing a Domin Servo Valve

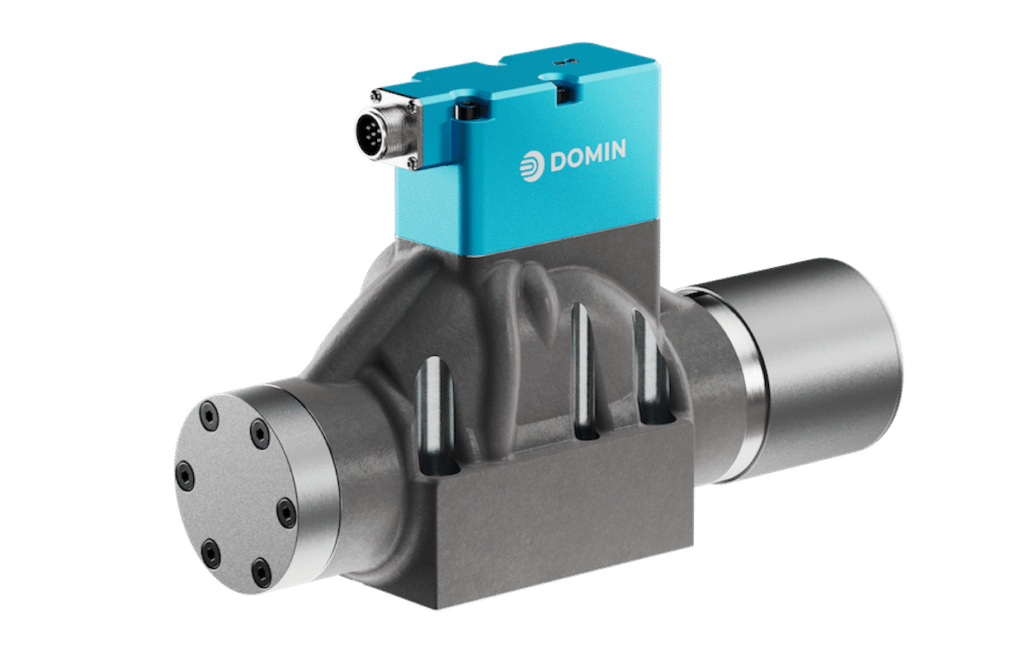

Domin offers a new class of hydraulic servo valves, combining the precision of two-stage designs with the robustness, efficiency, and safety of direct drive valves. Their product range includes four models depending on your application:

S4 Pro: World’s smallest direct drive valve

The S4 Pro is the smallest direct drive valve.

S6 Pro: Power density and reliability for most applications (most popular)

The S6 Pro delivers high power density, low leakage, and proven reliability in a compact package with an excellent power-to-size ratio.

S10 Pro: Efficiency for high flow rates

The S10 Pro is an efficient high-flow valve that offers fast response, low power usage, and is best for applications between 26 to 66 gpm.

S12 Pro: Expanding into higher power (Coming Soon)

The S12 Pro extends Domin’s capabilities into larger applications, building on the S10’s strengths but for even higher flow rates.

Get Domin Valves in days, not months

With lead time zero, we’ll ship your Domin valves out from our Ohio Warehouse same day or next business day.*

*As part of lead time zero, we aim to have the popular models in stock. We’re building up inventory levels and receive new stock regularly.