Hydraulic Pressure Intensifiers

Compact yet powerful, pressure intensifiers deliver a nearly instant pressure boost precisely when and where it’s required.

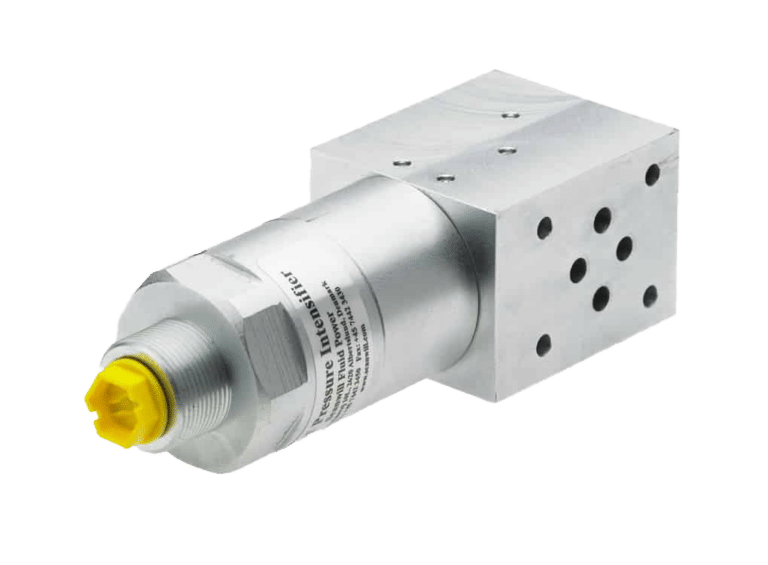

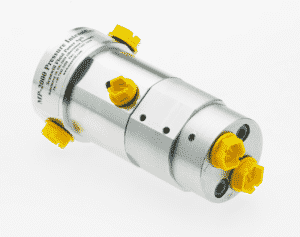

Hydraulic pressure intensifiers provide standard intensification ratios of up to 16 and yield maximum outlet pressures of 58,000 psi / 4,000 bar.

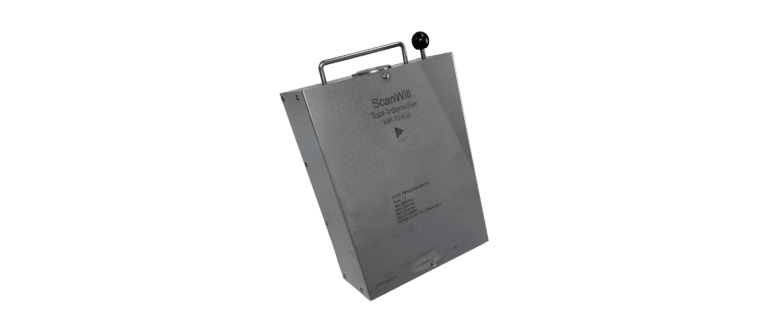

A tool intensifier is a safety device that intensifies the available pressure from your truck to power your 10,000 psi hydraulic tools.

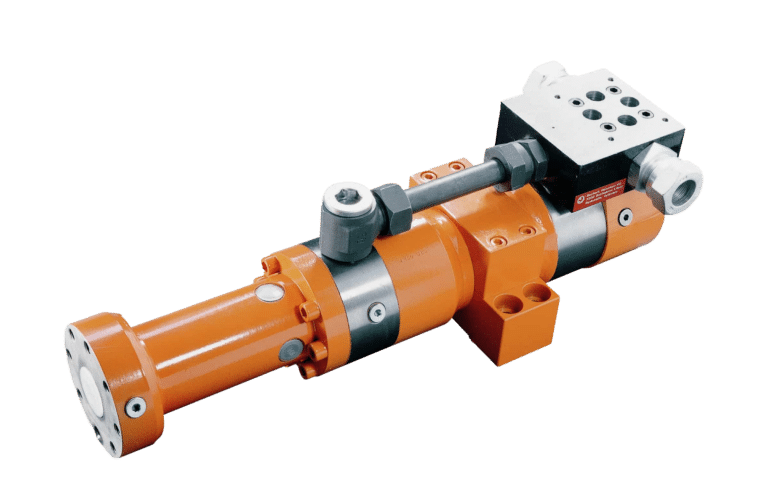

Single-Stroke Cylinder Type pressure intensifiers allow the input fluid to be the same as, or different than, the output fluid.

Need Support? We Can Help.

What Makes Us Different?

Easily add pressure to existing systems

Increase output pressure from a low-pressure supply without major investments or upgrades.

Increase energy savings for the entire system

Add pressure only where and when needed. Using low-pressure components with an intensifier cuts down on operating costs.

Fast lead times of 1 to 2 weeks

1-2 week lead times, so that you can work faster. For cases with higher urgency, faster delivery may be possible.

Pressure Intensifiers 101

What are Pressure Intensifiers?

Reciprocating or single-stroke cylinder intensifiers are used to increase the pressure output of an existing low-pressure system, giving a boost of pressure when and where it’s needed, yielding greater pressure.

How are Pressure Intensifiers Used?

Pressure intensifiers are powered by a pump, which is operating at a set pressure. The hydraulic intensifier consistently delivers flow until the output pressure has been reached. The flow from the pump enters the intensifier, where two pistons of different sizes (respective to the intensification ratio) pump the fluid, thereby intensifying it. In the process, waste flow is returned to the tank.

Pressure Intensifier Benefits

Application Examples and Solutions

A hydraulic pressure intensifier can be used for many applications. These include rupture tests on hoses, pipes, and containers; hydroforming; bolt tensioning; presses; and proportioning precisely defined volumes. It is also useful for demolition tools, such as stone crushing tools and hydraulic construction tools. Additionally, it can be employed in hydraulic power packs and workholding cylinders.

Mobile Applications

In mobile applications, such as cranes, pressure intensifiers increase the pressure in the cylinders during retraction and ensure sufficient pressure within the stabilizer. The outlet pressures for this application include 3625 psi/250bar – 4350 psi/300 bar.

Pressure Testing

Pressure intensifiers can be used to provide test pressures for hydraulic components at 7250 psi/500 bar – 11,600 psi/800 bar, and for tubes and hoses for diesel engines (2,000+ bar). Pressure can be boosted from existing HPUs to negate having to buy an additional test pump.

Hydraulic Tools

Power hydraulic tools with a pressure intensifier connected to an existing power source. Intensifiers can boost pump pressure from as low as 1,450 psi/100 bar to an operational range of 4,350 psi/300 bar – 11,600 psi/800 bar.