Flow Dividers

Flow dividers are available through Jahns. The addition of this product range to their catalog gives them a greater manufacturing depth and guarantees a higher-level of product quality. The company utilizes CNC machining centers to manufacture products in small batches. All products are checked in their test facilities before they leave the plant.

BROWSE BY CATEGORY

Flow Dividers

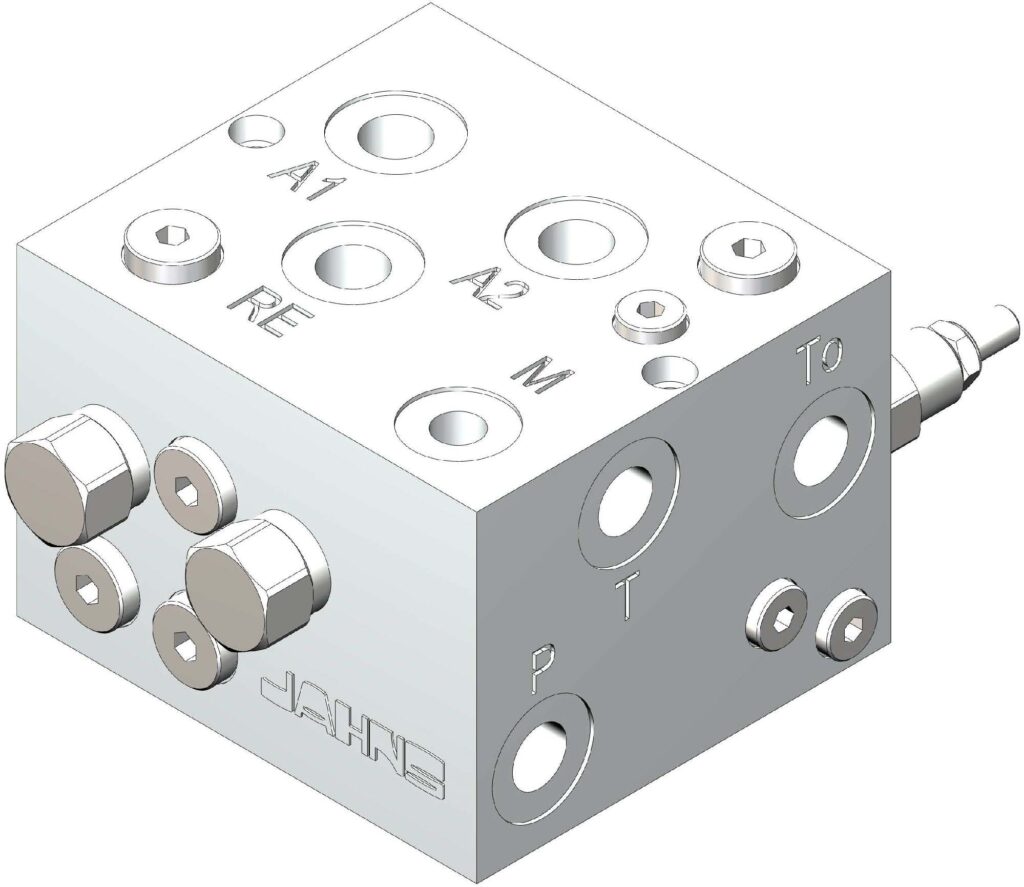

Valve Block Flow Divider

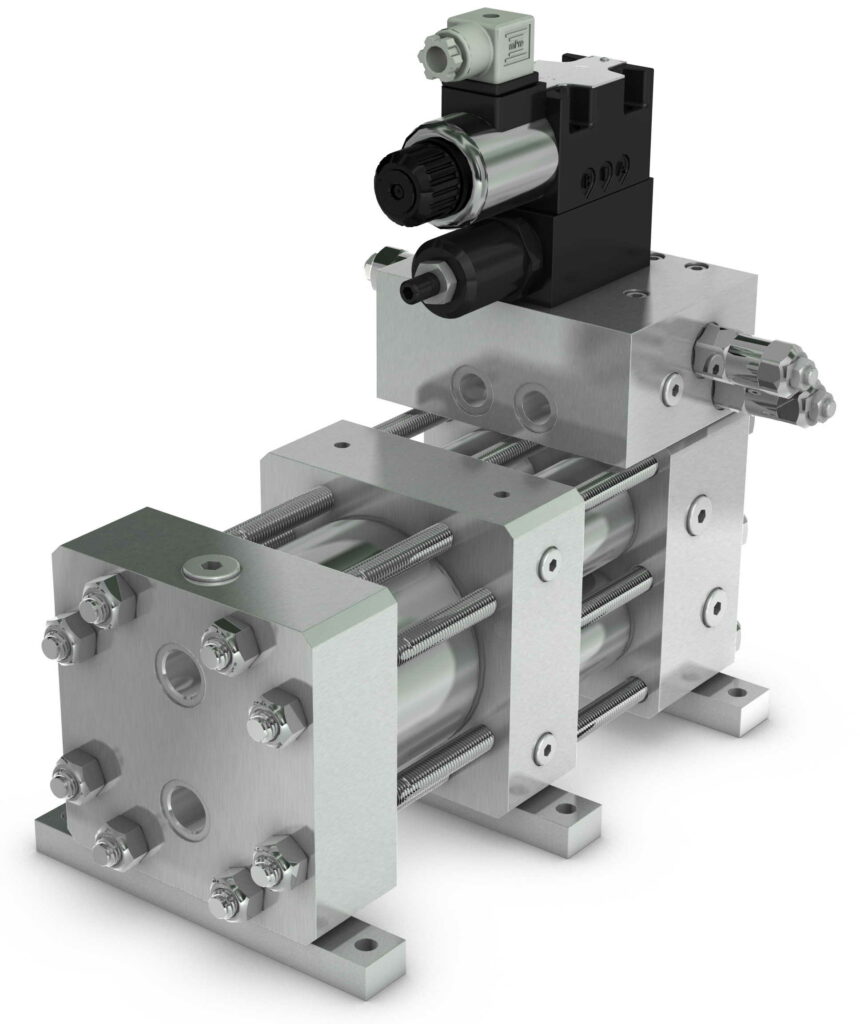

Volumetric Flow Divider

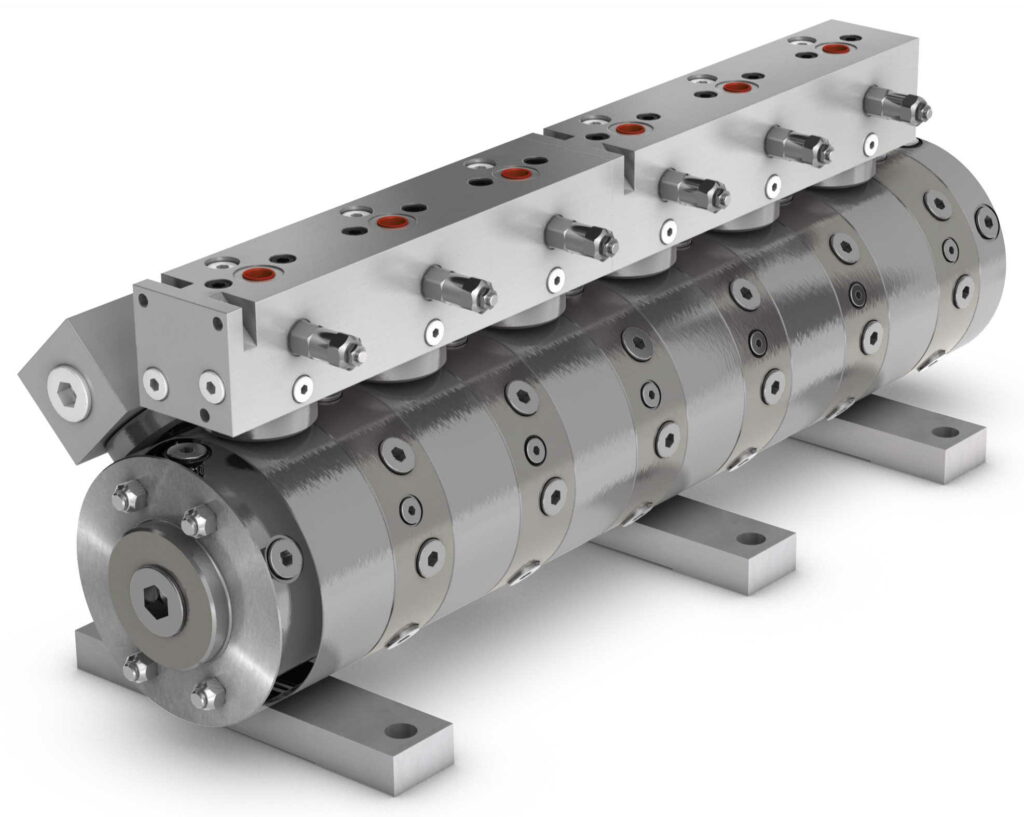

Radial Piston Flow Divider

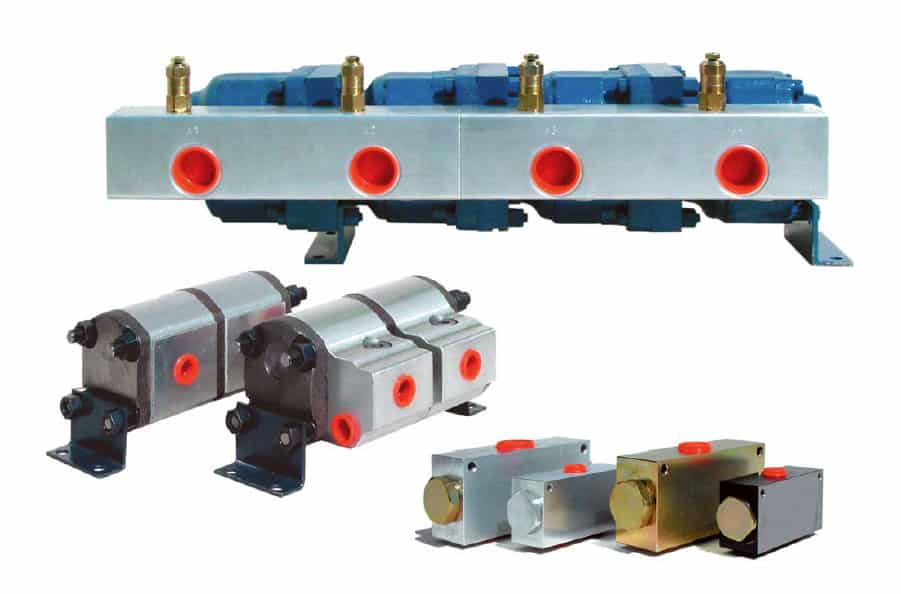

Hydraulic Gear Flow Dividers

What are Flow Dividers?

When you have multiple motors or cylinders connected to one pump, they cannot operate simultaneously because power is not evenly distributed to each component. Flow dividers simplify this problem by splitting the flow from one source into two or more output parts, which can be equal or unequal.

Common Flow Divider Designs

The most common flow dividers include the gear-type and spool design. For applications requiring extremely high accuracy (greater than 99%), radial piston and volumetric flow dividers work best.

Gear flow dividers (2 to 12 sections): Gear flow dividers are a cost-effective way to divide flow without losing a large amount of energy or heat. Comparatively to spool dividers, these devices are more tolerant of contamination.

Spool flow dividers (2 sections): Spool flow dividers rely on pressure compensation to divide flow. This design is limited to just two sections that can be split evenly, 50:50, or unequally. Spool flow dividers are well-suited for applications where synchronization is flexible and complete accuracy is not a requirement.

Radial piston flow dividers (2 to 12 sections): Radial piston flow dividers are designed with high accuracy in mind, but have higher pressure drops than gear flow dividers.

Volumetric flow dividers (3 to 8 sections, 2 to 12 chambers): The volumetric design functions by volume dosage and the exchange between a volume synchronizer and working cylinders. The volumetric design is for high accuracy applications and has lower pressure drops compared to radial piston dividers.

Flow Divider Applications

Synchronize components for pallet changers and lifting platforms: In the case where multiple cylinders need to move something in sync, flow dividers offer a great solution. This is useful, for example, in lifting platforms, where the platform must remain level to prevent binding in the guiding mechanisms as well as for the objects on top of the platform.

Use a flow divider as a pressure multiplier: Flow dividers can be utilized as a pressure multiplier. This type of hydraulic circuit can be used where a low-pressure circuit is already in use and where there is only need of high-pressure flow.

Using flow dividers as a hydraulic driver: This is achieved by adding an extra section of equal or greater displacement to the flow divider. The return line of this section is connected directly to tank so that it in effect works as a motor for the other sections in the flow divider thereby increasing their outlet pressures.

df