Volumetric Flow Dividers

In comparison to rotating flow divider types Jahn’s MZB and MLH lines are working only by volume dosage and the exchange between volume synchronizer and working cylinders.

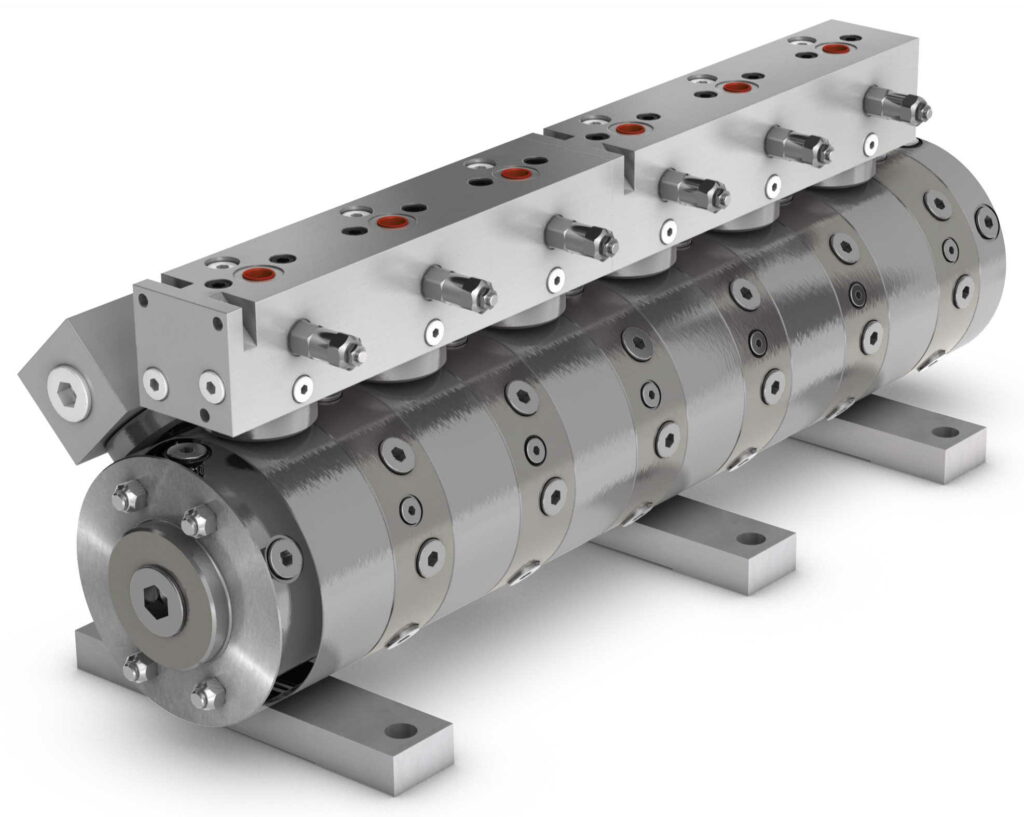

The dosage cylinders of MLH linear-stroke-volumetric-dividers are arranged around a master cylinder. Whereas a multiple in-line configuration of cylinders is characteristic for the multi-chamber volume synchronizer MZB.

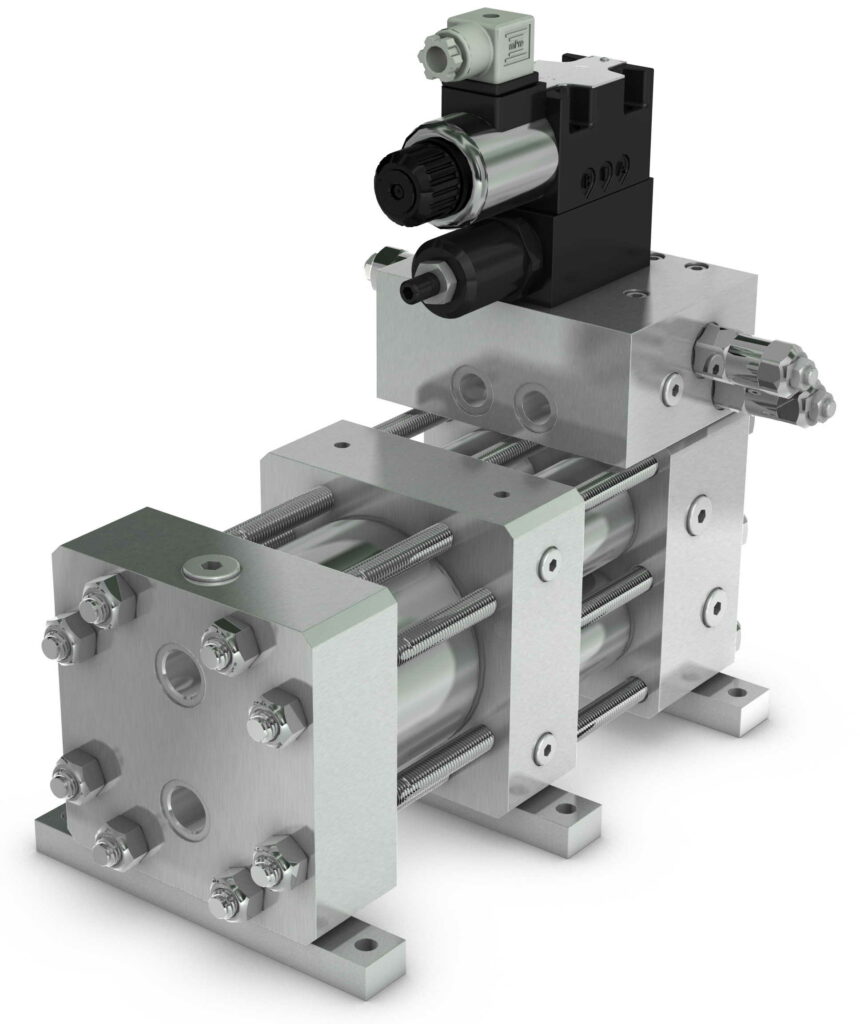

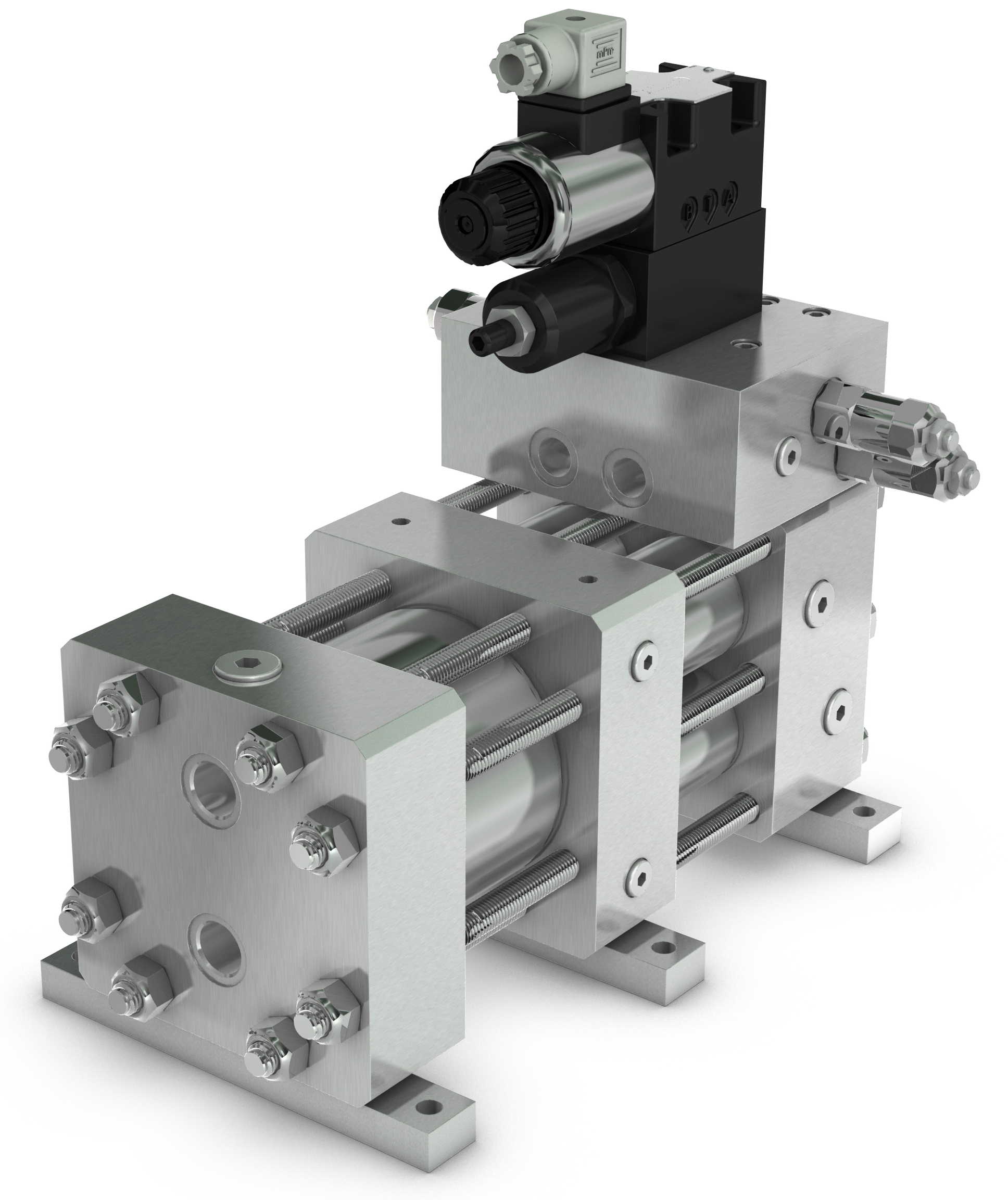

Flow Divider Linear Stroke MLH:

Designed for high-precision applications, this 3 to 8 section divider is available in 8 sizes. This style of divider achieves a superior level of synchronization, even compared to radial flow dividers, that is to say they are volumetric-dividers in the true sense of the word. Manifold blocks are available for all sizes to incorporate different functions. The operating pressure for all MLH devices is 3600 psi.

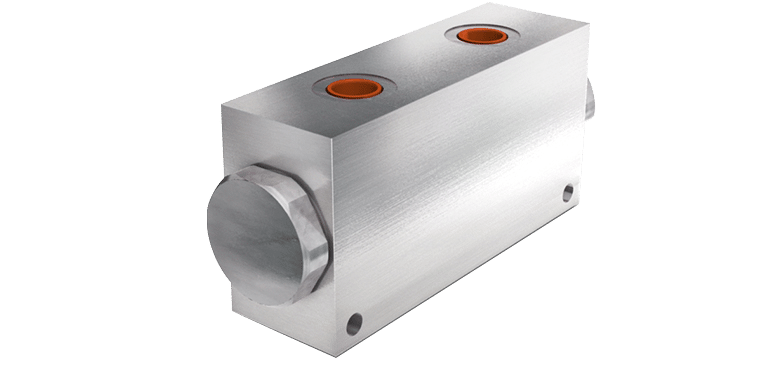

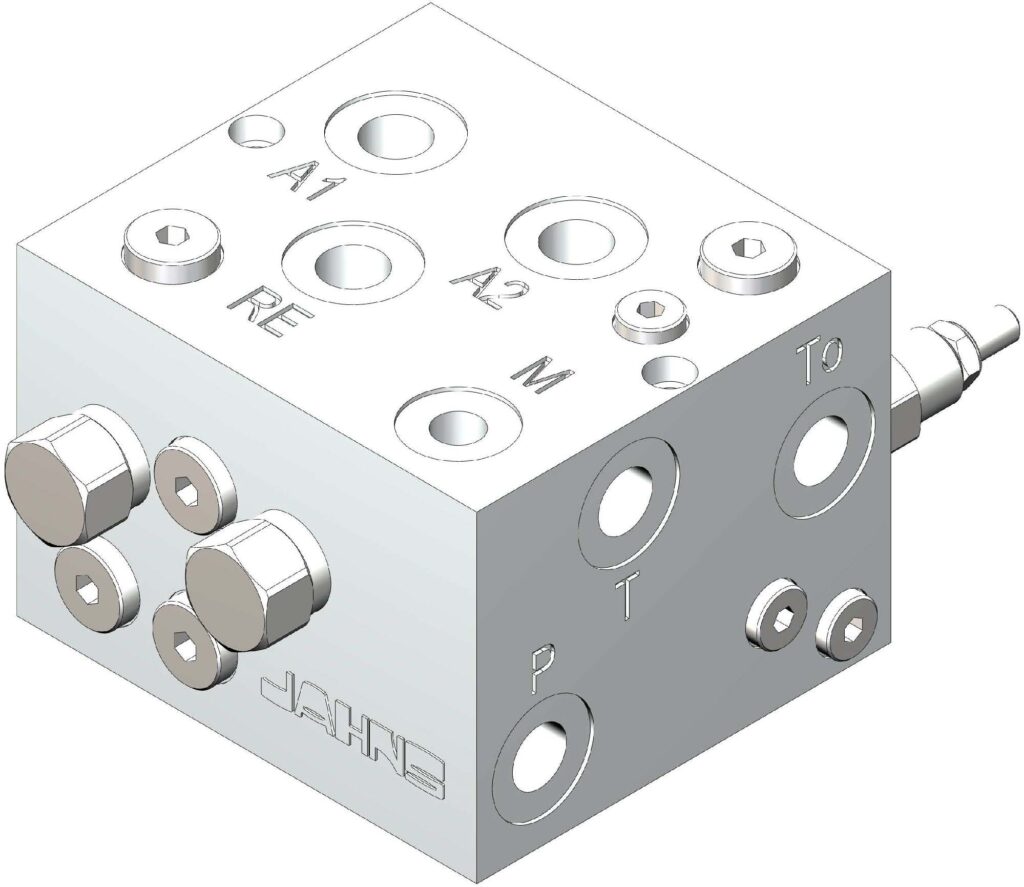

Flow Divider Multi Chamber MZB:

Designed for high-precision applications, this divider is primarily used in 2 to 4 chambers; however, these can be built with up to 12 chambers and is available in many sizes. The MZB also gives the advantage of a low pressure drop. The level of synchronization is equal to that achieved by the MLH series of linear stroke volumetric-dividers. The flow rate is 10 gal/min to 79 gal/min. The standard operating pressure is up to 3600 psi and can be increased on special builds to 6100 psi.

Technical Data + Ordering Codes

Jahns is a supplier and flow divider manufacturer for various applications including construction, mechanical, marine, and industrial.