Heat Exchangers

BROWSE BY CATEGORY

Heat Exchangers

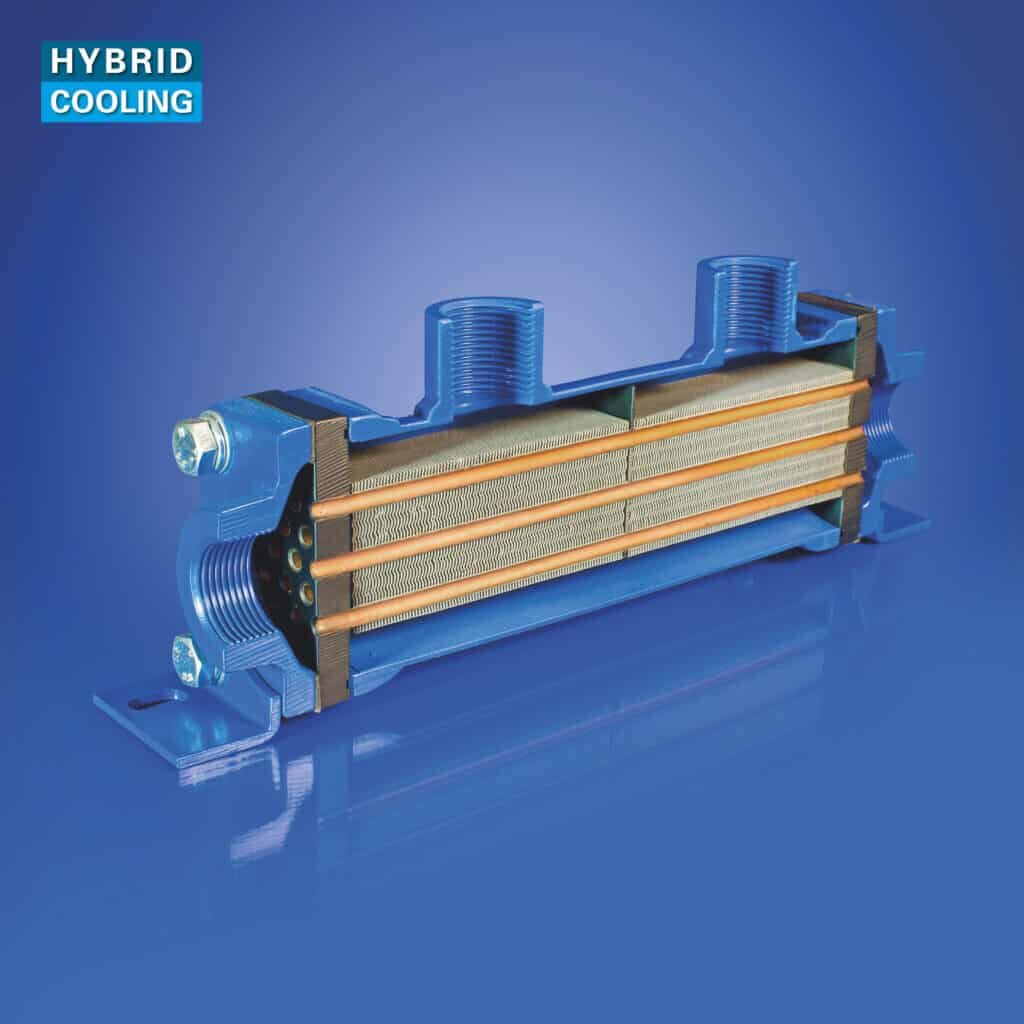

Heat Exchangers — Hybrid Coolers

Hybrid heat exchangers combine the advantages of shell & tube and plate heat exchangers. The larger surface area permits a physically smaller heat exchanger with better cooling capacity.

Heat Exchangers — Shell & Tube Cooler

Bare tube heat exchangers are an ideal choice for cooling high viscosity fluids and particle containing fluids that may clog a cooler with internal cooling fins.

Heat Exchangers — Fail-Safe Safety Cooler

Fail-safe coolers prevent the mixture of fluids should one of the cooling tubes fail. This is achieved by double wall tubes and safety switches that indicate a tube failure.

Heat Exchangers — Gear Box Cooler

Gear box coolers are standard cooler cartridges that are installed by means of screw threads in to a gear box or oil tank.

Heat Exchangers — Brazed Plate Cooler

Brazed plate heat exchangers are often used where a cost-efficient option is needed for smaller cooling loads.

Heat Exchangers — Screwed Plate Cooler

Screwed plate heat exchangers offer great flexibility by changing the number of plates and are easy to clean.