Hydraulic control accuracy improved on tire test rig with Domin S6 Pro Servo Valve

INDUSTRY

Testing

CHALLENGE

A leading tire manufacturer needed more accurate and repeatable hydraulic control to validate tire performance under rigorous, real-world test conditions. Existing systems struggled to deliver the precision and reliability required for high-volume, high-fidelity testing.

RESULTS

By integrating Domin’s plug-and-play servo valves, the manufacturer improved testing accuracy and repeatability without disrupting existing operations. The solution enhanced machine performance, reduced setup complexity, and aligned with sustainability goals through lower energy consumption while boosting test reliability.

KEY PRODUCT

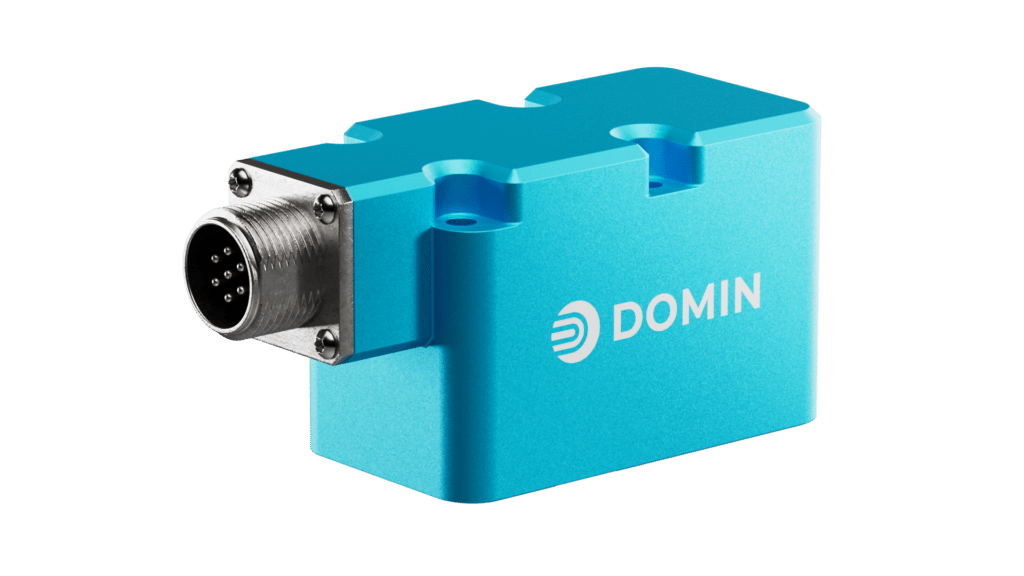

Domin S6 Pro Hydraulic Servo Valve

“Our testing machines require high accuracy hydraulic controls with repeatability and reliability and that’s exactly what we got with the Domin servo valves!”

Customer Feedback

Leading Tire Company

Overview

This case study was provided and written by our manufacturer, Domin, in collaboration with a leading tire manufacturer.

Tire testing is one of the most critical stages in the tire manufacturing process, ensuring that every product meets critical safety and performance standards. The rigorous testing combines both lab-based assessments and on-track vehicle tests to guarantee reliability under various conditions.

Precision and repeatability in tire testing

Hydraulic systems enable testing machines to move repeatedly under controlled conditions. This simulates real-world scenarios that tires will encounter once on vehicles and out on the road. The ability to precisely replicate these conditions allows engineers to gather reliable data on performance metrics such as wear, grip, and heat resistance. High performance hydraulic systems ensure the overall efficiency of testing processes.

In an industry where safety and performance are key considerations, precision and consistency are of primary importance. Testing machines used for tire (brake) testing, can run an average of 100,000 brake tests annually, proving the tire’s durability. This demonstrates the crucial role of hydraulic systems in maintaining the machine’s consistent and reliable operation.

MarQuipt approaches each case as a unique situation. “When people come to us with their boarding needs, the first questions we ask concern who’s getting on and off, how much help do they need, and if there are any pets involved,” mentioned Byrd.

Machines equipped with state-of-the-art technology can conduct more tests in less time without compromising quality. This not only accelerates product development but also ensures that manufacturers can bring safer and more reliable tires to market faster than ever before.

Market leading tire manufacturer demanded high accuracy hydraulic controls

In collaboration with a market leading tire manufacturer, Domin aimed to upgrade their existing test machine with a focus on increasing the accuracy and repeatability of their hydraulic controls, in order to ensure precise validation of tire performance under diverse conditions.

Domin’s plug-and-play solution could be installed in their current operations immediately once received. The S6 Pro ensures seamless operations and maximum productivity, thanks to its superior design and exceptional power density. It is designed to ensure that users can maximize performance whilst reducing energy consumption. This not only benefits the testing workflow but also aligns with sustainability efforts by reducing overall resource consumption.

Benefits of the S6 Pro Servo Valve

Customer feedback

“I am a new customer to Domin and I have to say that I regret not finding them sooner! We have fought with servo valves in the past to get them set up and operating correctly and accurately and with the Domin valves, they came ready-to-go…

“Our testing machines require high accuracy hydraulic controls with repeatability and reliability and that’s exactly what we got with the Domin servo valves!

“Their sales team was able to help me with finding a suitable replacement for the obsolete valves we have been having ongoing problems with and any questions I had about the installation and use of the valves was promptly answered by their team and they were great to work with throughout the whole ordering and delivery process! I will definitely be a repeat customer of Domin due to the quality of the valve and the attitude and professionalism of their team”

Revolutionizing the testing & simulation industry with breakthrough technology

Tire testing is not a one-size-for-all process; Each tire type brings its own unique set of characteristics and performance expectations, which in turn shapes the testing priorities and testing machines’ requirements.

Digitalization and automation in hydraulic systems enhances performance and precise control. This not only accelerates the testing process but also provides invaluable data insights that enable can help optimize the development cycle.

Domin Valves offer the opportunity to optimize performance and enhance capabilities, enabling more controlled and repeatable tests, addressing the evolving demands of modern testing and simulation applications. To discuss leveraging integrating Domin’s solutions in testing and simulation, contact us today at us@icfluid.com or +1.419.661.8811.

More details on Test and Simulation Performance are available here.