Universal Hydraulik

Superior Quality. Custom Design. USA and European Manufacturing.

Since 1993, Universal Hydraulik has been designing hydraulic systems, cooling systems, and heat exchangers that are used in many different applications all over the world. Own-make heat exchangers started production in 2002.

Known for customized heat exchanger solutions, Universal Hydraulik has been continuously certified to DIN ISO 9001 since 1997 and holds certificates for BV, DNV, Germanischer Lloyd and others.

What does Universal Hydraulik stand for internationally?

Why Universal Hydraulik?

There are four main reasons to utilize Universal Hydraulik heat exchangers:

No Flushing Required

Universal Hydraulik’s proprietary manufacturing process creates little to no contamination from welding and other materials that get transferred to the final unitThus, no flushing is required, saving time and money.

In addition, Universal Hydraulik uses robots for welding, ensuring consistent and high-quality welds.

Tubular heat exchangers made in Universal Hydraulik’s production facilities in Germany and the Czech Republic are subject to an in-process testing sequence comprising five different steps, starting with the tube inspection (measurement of wall thickness) to the final leak test on the entire cooling system. These tests ensure only high-quality and reliable products get shipped.

More Efficient by Design

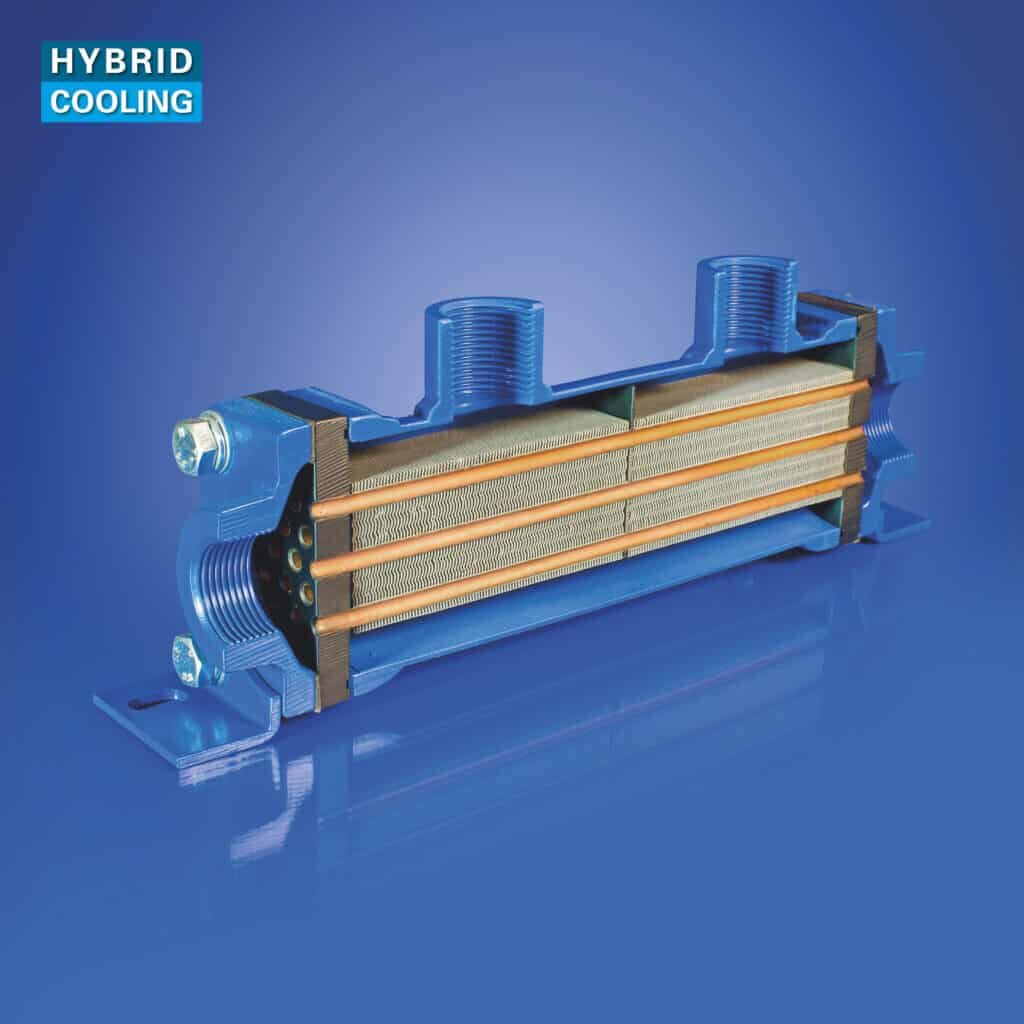

Universal Hydraulik’s “hybrid cooler” line offers high performance due to the utilization of plates or “fins” on the oil side to allow for more efficient heat transfer in a more compact space. This unique line combines the advantages of plate heat exchangers with the benefits of shell & tube (S&T) heat exchangers. Universal Hydraulik’s “hybrid cooler” line features:

Industry-Leading Fail Safe Coolers

Fail-safe coolers are often used in marine, offshore oil, power and steel plants, and other applications where natural water is used as the cooling medium and, for reasons of environmental or mechanical protection, mixing of mediums needs to be avoided. Simply put, Universal Hydraulik’s fail-safe coolers are two heat exchangers in one, ensuring 100% safety if the outer or inner tube gets destroyed. Built-in sensors detect if there is a pressure loss of the control fluid and provide electronic warning signals so that no or very minimal amount of oil is released into the environment. The materials of the safety heat exchanger and the combination of tubes and seals can be customized accordingly the application.

Largest Size Offerings in the Industry

Two Universal Hydraulik heat exchanger series can be manufactured in sizes up to 395 gpm (1,500 l/min) volume or 1,300 hp (1,000 kW) cooling capacity; the SCM series and the EKM series.

SCM Series

The SCM series (larger diameter internal tubes) is particularly effective due to the additional cooling area, produced by aluminum fins pushed over the bank of tubes with metal-to-metal contact. The SCM range of heat exchangers has a cooling surface of from 6 m2 to 29 m2. The SCM series is primarily sold to applications where there is poor water quality such as in Asia and South America.

EKM Series

The EKM series (standard size internal tubes) is a logical further development of a tube-bank heat exchanger for a wide range of industrial applications. This range is particularly effective due to the additional cooling area and offers a heat exchange performance of 230 kW.

Applications Include:

Custom Designs

Universal Hydraulik offers a convenient customization program which allows customers to have oil coolers engineered for their specific application—without the hassle or purchase minimums. This can include special porting, sizing or materials.

Approximately 50% of Universal Hydraulik coolers are custom. Custom projects include 3D drawings and exact cooling calculations at no additional cost. Universal Hydraulik works with OEM’s to deliver custom solutions.

Universal Hydraulik oil coolers are available in many different material combinations for any environment:

For a complete list and description of Universal Hydraulik heat exchangers, visit https://www.icfluid.com/products/heat-exchangers/ or call 1-877-423.5843.