Butterfly Valves

Hytorc butterfly valves save time for the technician working on the hydraulic system by not having to drain the reservoir. Designed for low pressure pump suction lines up to 230 psi (15 bar).

Need Support? We Can Help.

What Makes Us Different?

Save valuable space

Lightweight, compact, and easy to install—butterfly valves outperform ball valves in mobile systems.

No draining of reservoir

With the tank isolated, routine maintenance can be streamlined by not having to drain the reservoir beforehand.

28% more oil volume

Compared to ball valves, butterfly valves optimize flow efficiency without increasing component size.

Butterfly Valve 101

What is a butterfly valve?

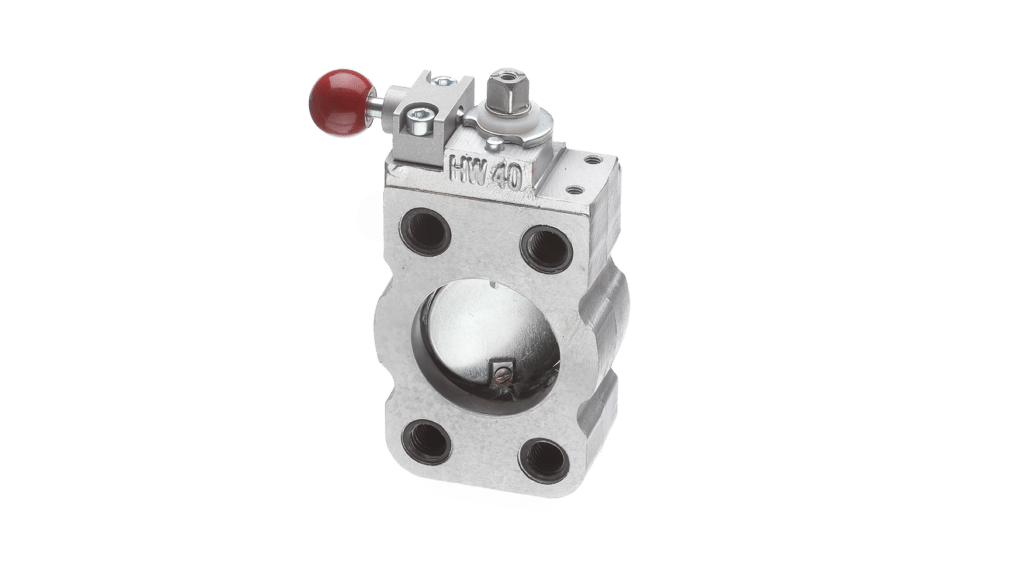

Butterfly valves, also known as shut off valves, are 90°, quarter-turn valves used for regulating flow. When installed at a tank outlet, flow can be shut off without draining the reservoir.

Butterfly valves vs ball valves

In mobile applications where ball valves struggle to fit within design constraints, butterfly valves serve as an effective solution. Shut off valves offer a shorter and lighter profile. As the pipe size and nominal diameter increase, the space and weight advantages of butterfly valves become even more pronounced.

For a 1.25” pipe, butterfly valves are 63% shorter and 50% lighter than a ball valve.

|

Butterly Valve |

Ball Valve | |

|

Length |

1.4 in (35 mm) |

3.7 in (95 mm) |

|

Weight |

1.1 lbs (0.5 kg) |

2.2 lbs (1 kg) |

On a 4″ pipe, those benefits scale dramatically, with butterfly valves measuring nearly 77% shorter and 71% lighter.

|

Butterly Valve |

Ball Valve | |

|

Length |

1.7 in (42 mm) |

7.4 in (190 mm) |

|

Weight |

3.4 lbs (1.57 kg) |

12.3 lbs (5.56 kg) |

How does a butterfly work?

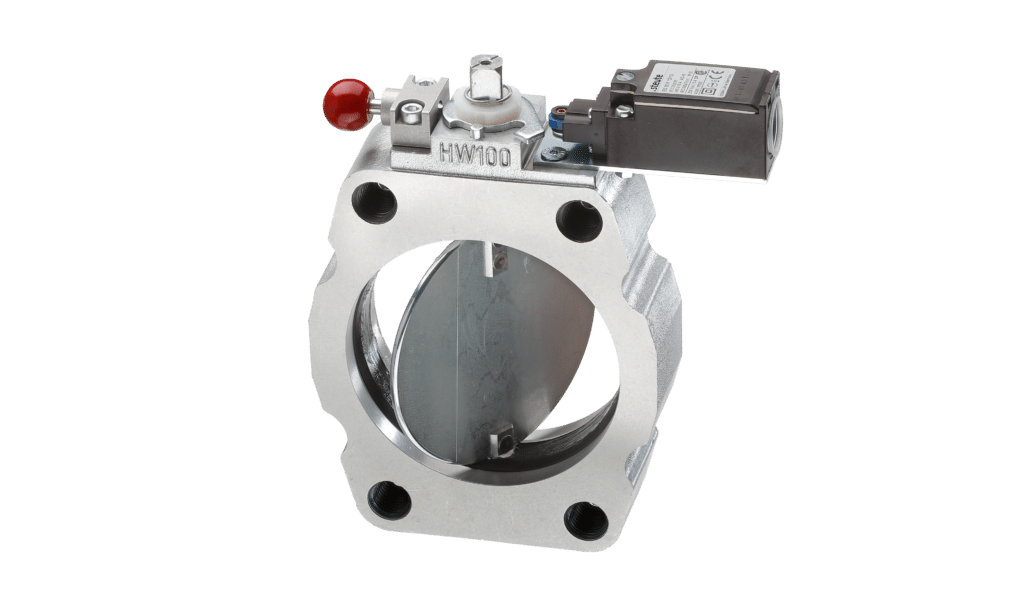

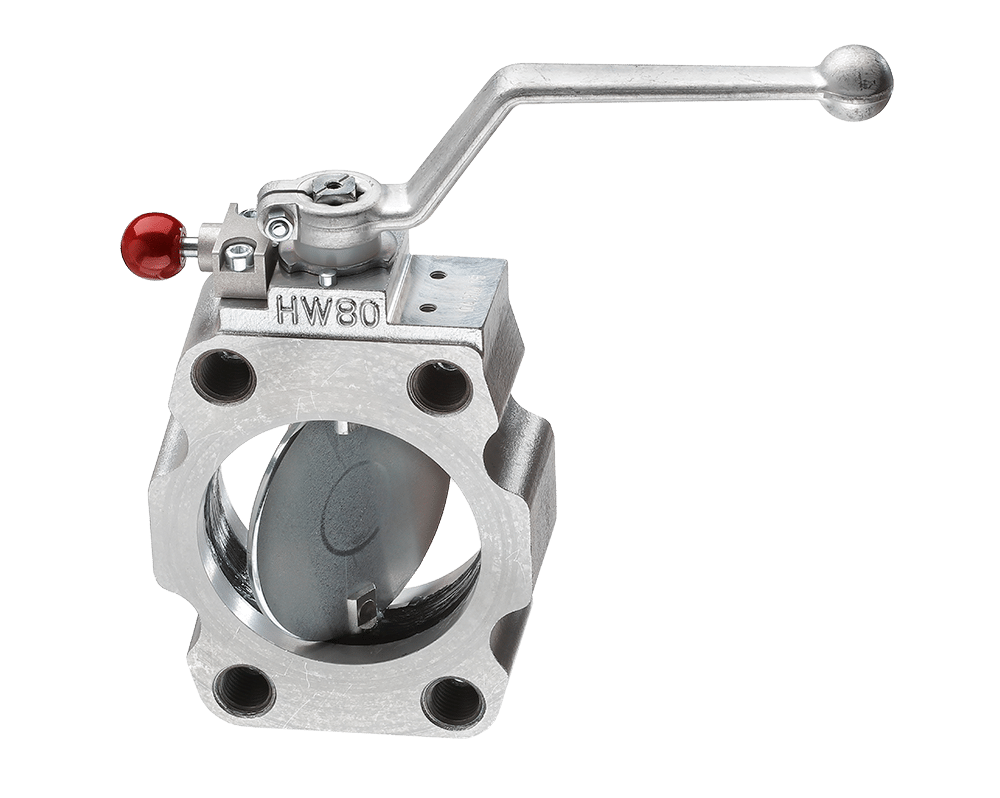

Hydraulic shut off valves are composed of a disk, stem, and body for precise flow control. The disk is the flow control element that pivots on the stem housed within the valve body. In the open position, it aligns with the flow direction to minimize resistance. When closed, it seals against the valve seat to prevent flow. A locking mechanism ensures the valve remains in the desired position during operation. Optional limit switches enable remote position monitoring for automating system diagnostics and control.

Butterfly Valve Benefits

How to Choose a Butterfly Valve

Butterfly valves are designed for low-pressure suction lines, that handle up to 230 psi (15 bar). Choosing the right model depends on critical factors such as the valve size, mounting style, and position control.

1. Select the correct size/nominal width

Start by measuring the pipe’s internal diameter to select the appropriate valve size. Hytorc shut off valves range from 1.25 to 5 inches (32 to 125 mm), ensuring compatibility with various systems.

2. Determine mounting style

Butterfly valves can be mounted directly onto the hydraulic reservoir with a welded flange, conforming to the typical SAE J518 standard.

While not required, it is recommended to install butterfly valves with a compensator for added protection and alignment. This is achieved by incorporating bushings into the valve assembly. The bushings let you mount the shut-off valve to an SAE connection. They screw into the SAE flange, adapting its thread size to match the fixing screws.

Alternatively, if the reservoir flange is already tapped correctly, bushings aren’t required.

3. Consider a limit switch

A limit switch prevents the hydraulic pump from activating when the valve is closed. If connected to PLC controls, this feature protects equipment by preventing the pump from running dry.

All Hytorc valves are preinstalled with a cam, allowing a limit switch to be equipped at any time with just two screws.

Applications and Solutions

Hydraulic butterfly valves are commonly used on low-pressure suction lines across many industries, including naval, automotive, forestry, construction, wind energy, and aerospace.

Forestry and Recycling (Horizontal grinders)

Horizontal grinders play a critical role in forestry and environmental recycling, handling everything from land clearing and mulch production to biomass processing and construction debris. In these applications, hydraulic systems must be equipped with fail-safe mechanisms to prevent fluid loss. As one functional benefit, butterfly valves serve as emergency shutoff devices, minimizing the risk of oil spills when hoses or other hydraulic components fail.

By automatically sealing off flow, these valves help protect both equipment and the surrounding environment due to reduced oil volumes being leaked. This is especially vital given the diverse operating environments of horizontal grinders, which often include sensitive ecosystems and waterways. Just one gallon of oil can contaminate a million gallons of water—consider that against a 70-gallon hydraulic tank, and the stakes become clear.