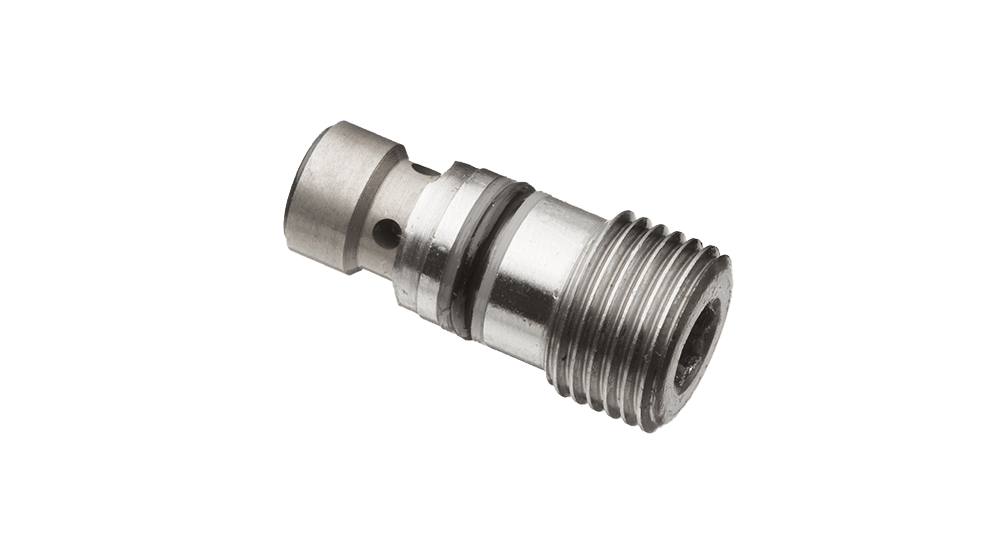

Hydraulic Check Valves

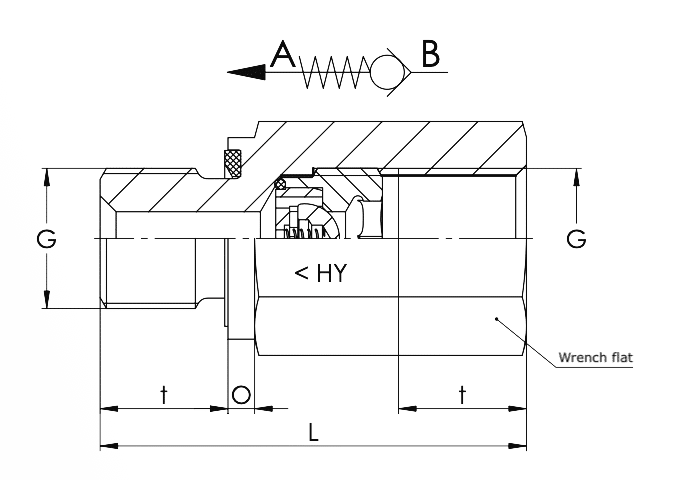

Check valves protect system integrity, prevent backflow, and save space. Hytorc’s half-ball seat design delivers a compact, economical solution rated for 10,000 psi (700 bar).

Need Support? We Can Help.

What Makes Us Different?

Compact installation height

The unique, half-sphere design maximizes space, especially in mobile hydraulics where every millimeter matters.

Power up to 10,000 psi

While most competitors are limited 3,000 psi, our valves are engineered to meet the demands of high-pressure applications.

On-demand experts

Our team stays responsive to your specifications while ensuring fast lead times of 6-8 weeks.

Check Valve 101

What are check valves?

Check valves are a type of shutoff valve that block oil flow in one direction and allow it to flow freely in the other.

How are check valves used?

Check valves are essential for protecting pumps, actuators, and other components by ensuring pressurized fluid flows only in the intended direction. Ball check valves use a sphere that moves in response to fluid pressure. When fluid moves forward, the ball is pushed away from the valve seat, allowing flow. If flow reverses, the ball returns to the seat, sealing the valve and preventing backflow. This mechanism helps maintain system pressure, prevent contamination, and ensure efficient operation in almost every application.

Check Valve Benefits

How to Choose a Check Valve

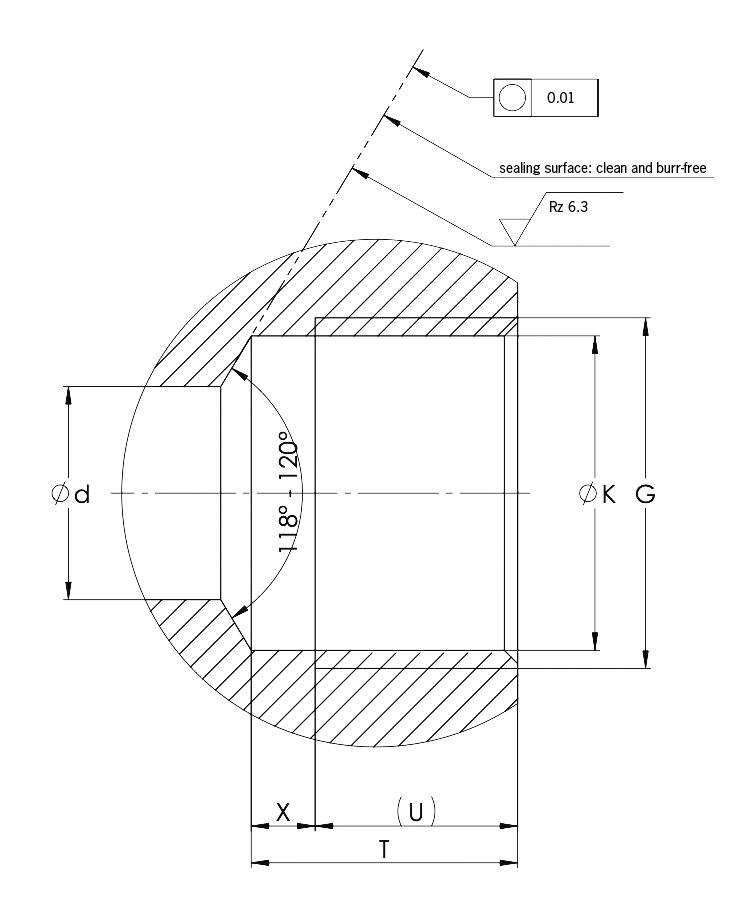

Verify that the selected valve is rated for your system’s pressure. Hytorc can accommodate up to 10,000 psi (700 bar).

1. Determine required flow rate

The flow capacity determines the nominal size of a valve. Selecting the right size ensures optimal performance and avoids issues like inefficiency or equipment damage.

For example: If your application requires a flow rate of 5 GPM, your selected valve would utilize a G ¼ or M14 x 1.5 thread.

|

Max Flow Rate (GPM) |

Max Flow Rate (LPM) |

Thread (BSP) |

Thread (Metric) |

Model Options |

|

0.5–0.8 |

2–3 |

N/A |

M6 |

RVA2, RVB2 |

|

1.1–1.6 |

4–6 |

N/A |

M8X1 |

RVA3, RVB3 |

|

2.1–2.6 |

8–10 |

G1/8 |

M10X1 |

RVA4, RVB4, RVE4, RVF4, RVG4 |

|

4.7–6.6 |

18–25 |

G1/4 |

M14X1.5 |

RVA6, RVB6, RVE6, RVF6, RVG6 |

|

9.2–11.9 |

30–45 |

G3/8 |

M18X1.5 |

RVA8, RVB8, RVE8, RVF8, RVG8 |

|

15.9–18.5 |

60–70 |

G1/2 |

M22X1.5 |

RVA10, RVB10, RVE10, RVF10, RVG10 |

|

23.8–26.4 |

90–100 |

G3/4 |

M27X2 |

RVA16, RVB16, RVE16, RVF16, RVG16 |

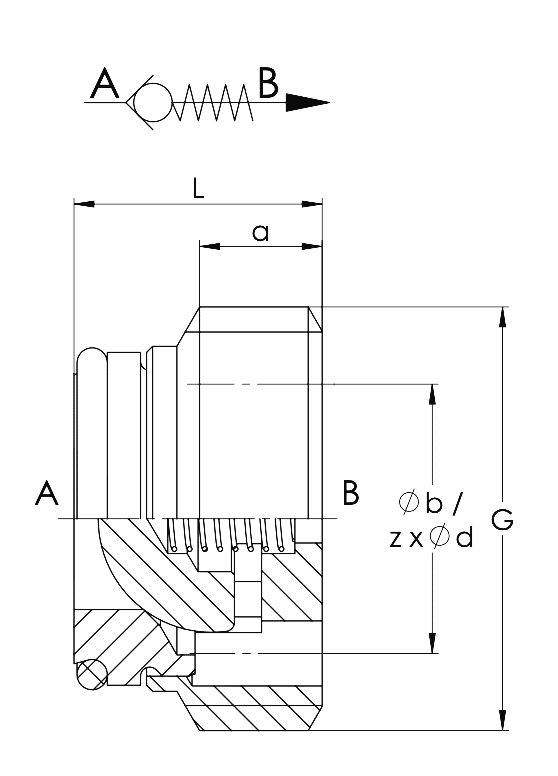

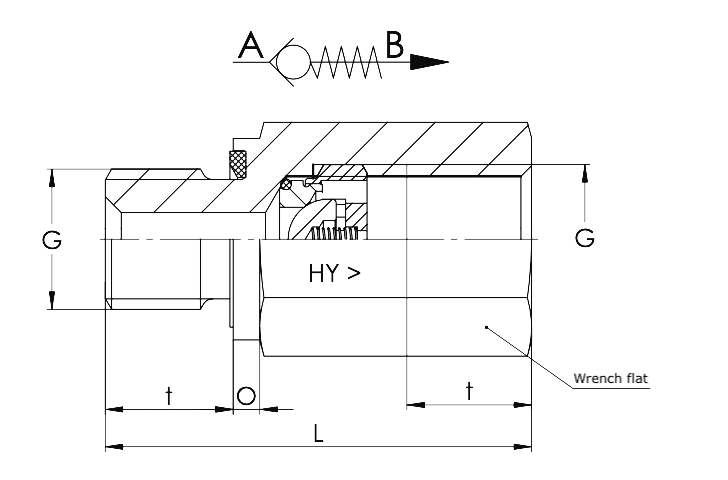

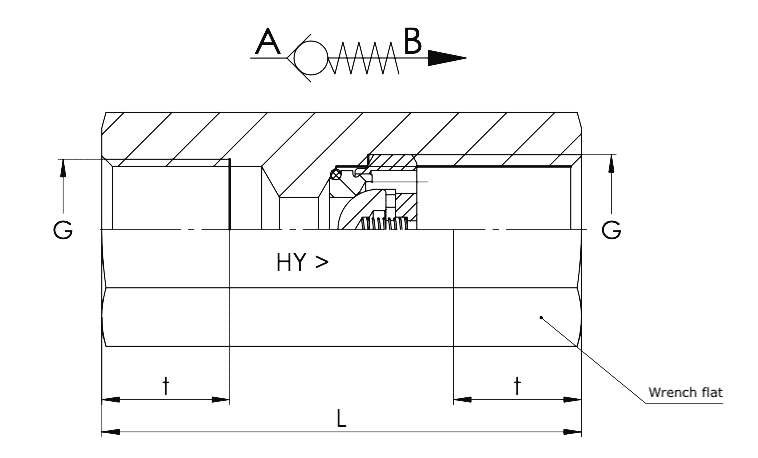

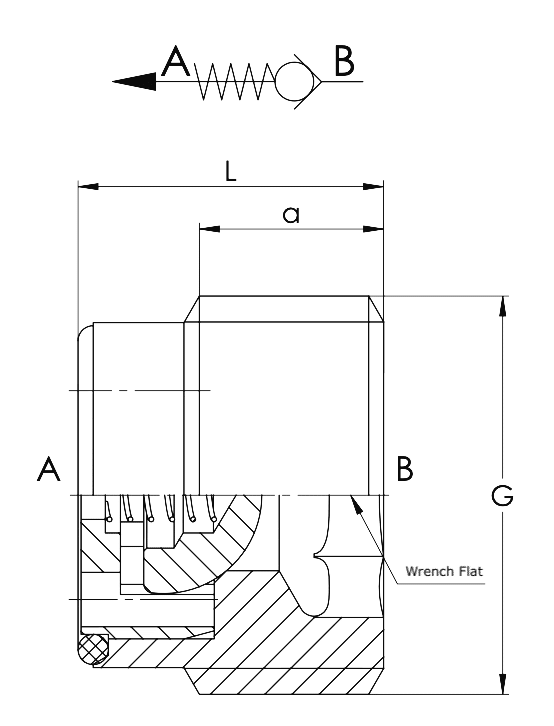

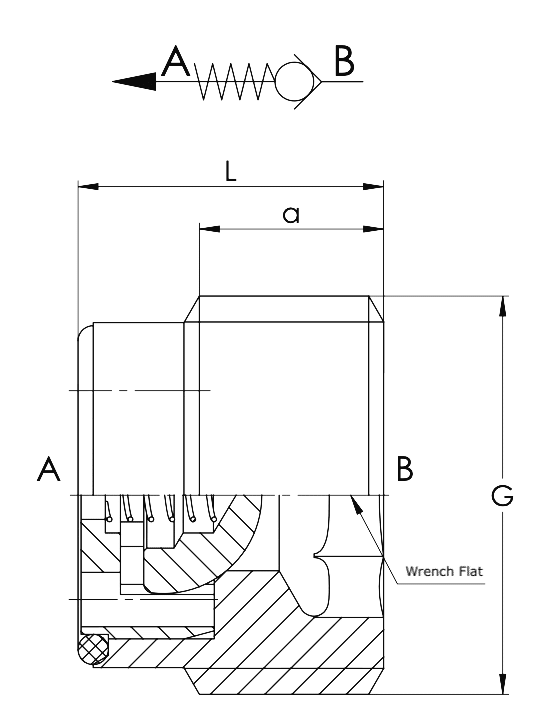

2. Select valve type

Hytorc valves are available in two primary configurations: screw-in and in-line (cage) designs. Both of the following flow direction options are available for each type:

Use the widget tool below to find the right check valve type for your application.

|

Screw-in Mounting |

Drill Mounting |

In-line Mounting | |

|

Port A to B (Model) |

RVA |

RVA |

RVE, RVG* |

|

Port A to B (Graph) |

|

|

*Internal threads on both ends |

|

Port B to A (Model) |

RVB |

RVB |

RVF |

|

Port B to A (Graph) |

|

|

|

3. Consider material

Consider the fluid being used and the operating environment to determine the material. Check valves are available in steel or stainless steel, with stainless steel being the preferred choice for applications exposed to moisture, high pressure, high temperatures, and aggressive fluids.

Additional factors

After selecting the size, type, and material, a model can be selected. For proper installation, please follow the manufacturer’s recommended specifications for cracking pressure and apply the correct tightening torque. These installation details are available on the specification’s page.

Applications and Solutions

Check valves are used across a wide range of industries to ensure unidirectional flow and prevent back flow in hydraulic systems. From heavy machinery and agriculture to aerospace, marine, and energy sectors, these valves support critical functions like lifting, steering, braking, and pressure control in demanding environments.

Mobile Equipment (Tractors, Excavators, Cranes)

Check valves control flow and prevent backflow in nearly every industry. In applications like tractors, cranes and excavators; hydraulic components must integrate seamlessly into tight spaces. Compared to traditional valves, Hytorc has created a unique, half-sphere design, reducing the overall height to minimize space, and an optimized seat for superior sealing.

High-Force Applications (Spreaders and Cutters)

The power-to-size ratio is key when designing hydraulic tools for demanding environments. While most components typically handle up to 3,000 psi, Hytorc check valves enable spreaders and cutters to achieve 10,000 psi without sacrificing in compactness. The capability to generate more force while maintaining a small profile allows for greater mobility and ease of use, especially in rescue operations where lightweight, maneuverable tools are essential.