Shock Dampers for Snap Through

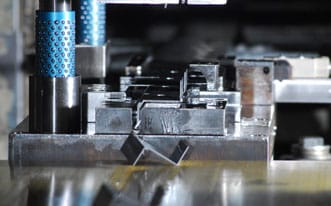

Shock dampers are one of the best kept secrets of the metal stamping industry. Many people have heard of them but most do not realize the positive effect they can have on a die or press.

At the instant of breakthrough during blanking operation, the presses and dies are subjected to severe loads, commonly referred to as snap-through force. This eventually results in damage to the bearings, seals, gibways and increased die wear. With the Hylatechnik Blanking Stroke Dampers, the life of the press and dies is extended. In addition, noise and vibration are significantly reduced.

How Do Shock Dampers Work?

Essentially the dampers are a set of oil-filled cylinders set beneath the ram. The cylinders are set to contact the ram or slide just prior to punch with the material. The oil in the cylinders is forced through an orifice designed to limit ram speed to normal velocity while providing little additional force on the press drive. The rapid and damaging acceleration/deceleration that can occur at the instant of punch break through is dampened by the orifice controlled speed of the cylinder.

Below is data from an actual demonstration of the Hylatechnik Damper at a customer’s facility:

400 Ton Press @ 32 s.p.m. Without Hylatechnik Shock Dampers

1st Stroke:

Working tonnage – 362 tons

Reverse tonnage – 125 tons, 31%

2nd Stroke:

Working tonnage – 362 tons

Reverse tonnage – 129 tons, 32%

With Hylatechnik Shock Dampers

1st Stroke:

Working tonnage – 379 tons

Reverse tonnage – 3 tons, 0.75%

2nd Stroke:

Working tonnage – 379 tons

Reverse tonnage – 3 tons, 0.75%

Shock dampers may make a surprising positive difference on your press. Call 877-423-5843 to schedule a Hylatechnik Shock Damper demonstration on a heavy snap-through application.

Recent Blogs

Case Study: SKD Automotive...

Founded in 1937 and based in Troy, Michigan, SKD Automotive Group manufactures and supplies metal stampings, components, and weldments to… Read More »Case Study: SKD Automotive Group | Hylatechnik Shock Dampers

read moreReverse Tonnage Reduction with...

Hydraulic shock dampers can be beneficial to reduce the effects that come from reverse tonnage. This device can reduce wear… Read More »Reverse Tonnage Reduction with the Use of Shock Dampers

read more