Davits redesigned around Eckart Actuators to reduce costs and save space

INDUSTRY

Marine

CHALLENGE

Manually rotating davits can be dangerous. The user is forced to physically push and pull the tender boat, creating a safety hazard. However, providing powered rotation for smaller davits was not always feasible due to cost and design constraints.

RESULTS

Integrating Eckart E3 rotary actuators into MarQuipt davits resulted in more compact designs due to the actuators fitting into the existing housing of non-powered models. This allowed MarQuipt to offer powered rotation as an upgrade without needing to significantly change the davit’s design or increase its size. As a result, MarQuipt was able to offer smaller davits with powered rotation and reduce the overall cost to the customer.

KEY PRODUCT

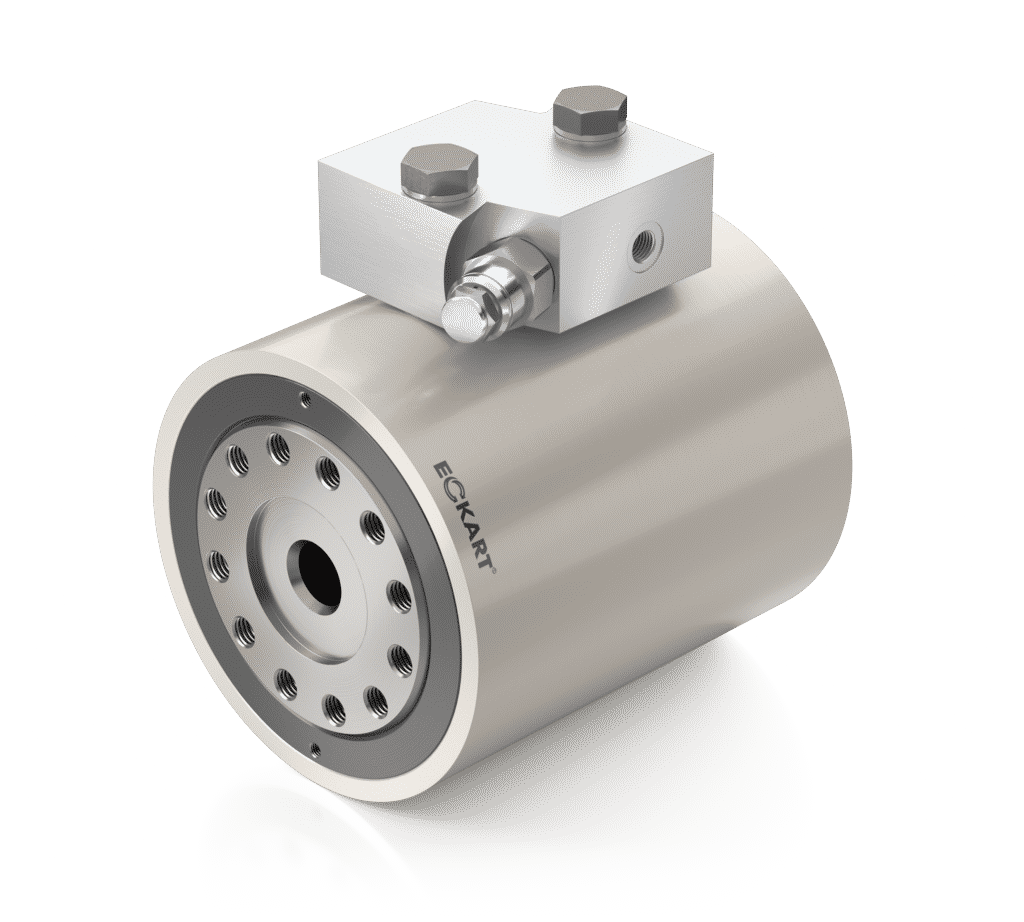

Eckart E3 Hydraulic Rotary Actuator

“Because we could fit the rotary actuator inside our existing housing, we could reduce some costs and make that option to power rotary things more attractive.”

Lee Byrd

Vice President of Marquipt

Marquipt

MarQuipt is a marine and yachting equipment manufacturer that prioritizes safety and convenience in their designs, catering to a diverse customer base with a range of needs. The company specializes in creating equipment like stairs, ladders, gangways, davits, and cranes, all aimed at facilitating easy and safe boarding for people and the handling of tenders.

Boarding equipment

Finding an optimal boarding solution for each boat and the persons using it requires addressing various details as well as determining the needs of the people involved. Safe and secure boarding is MarQuipt’s specialty. Some boats, for example, are not universally accessible or designed for easily getting people on and off the boat. MarQuipt’s products are designed to make this process easier.

“Some boats don’t really provide a good way to get on or off,” Byrd explained. Some individuals can easily step across the gap between the boat and dock, while others require more assistance and security to help get them across. Other times, there is a large height difference to accommodate as well as the gap.

MarQuipt approaches each case as a unique situation. “When people come to us with their boarding needs, the first questions we ask concern who’s getting on and off, how much help do they need, and if there are any pets involved,” mentioned Byrd.

Some cases may involve the installation of an articulating staircase where handrails and no gaps between the dock and boat are imperative details. In other situations, a vertical ladder that can be easily stowed away or some alternate arrangement may be a better solution.

“We encounter many different boarding situations in accommodating people who require various degrees of assistance,” said Byrd.

Lifting equipment

In addition to boarding equipment, MarQuipt also manufactures a range of davits and cranes which are essential for safely lifting and maneuvering tender boats onto yachts and other vessels. Similar to the challenge of providing appropriate boarding equipment, lifting equipment must also be carefully specified to meet the needs of each vessel.

Hydraulic rotary actuators safely power rotate davits and cranes

In some smaller davits, tenders are lifted with a boom and manually rotated with a tagline, while higher capacity davits and cranes are fully powered hydraulically. This involves a hydraulic boom and a hydraulic rotary actuator installed in the base of the machine. The boom and cable lift the tender, while the actuator rotates the boom and tender 180° or 360° to easily move the tender and bring it aboard.

While full hydraulic rotation has traditionally been a feature reserved for higher capacity davits and cranes, MarQuipt has found it beneficial to also offer powered rotation in smaller davits to provide improved safety and convenience. For example, some tenders are stowed in locations where safe handling becomes more challenging. A davit mounted on an upper aft deck can be dangerous to manually rotate, as the user must manually push and pull the tender to rotate it into position. It becomes more challenging if the upper deck is not provided with safety railings.

For these and other reasons, offering powered rotation provides for a safer alternative to manually rotating the davit and tender, even when the tender is relatively small and lightweight. “It is much more secure to be able to push a button and have the davit rotate under power even if the tender only weighs 800 lbs or 1000 lbs,” Byrd explained.

Eckart’s compact design offer several benefits

Adding Eckart’s hydraulic rotary actuators into a system can be simply done due to its compact, helical spline design.

“They’re compact and self-contained, so we can more easily fit them inside of our equipment,” Byrd explained.

Eckart’s rotary actuators contain their own rotation stops, which means the device did not have to be specially engineered to fit MarQuipt’s equipment. Another advantage of Eckart’s rotary actuators is that they can be easily replaced if needed.

“They’re easy to swap out if we’ve got a problem. We’ve designed our davits to make removal for repair or replacement easier than with some other actuators,” said Byrd.

Eckart E3 Hydraulic Rotary Actuator

Davits redesigned around Eckart Actuators to reduce costs and save space

Marquipt designed some of its davit models, such as the MarQ series and TenderLift 2, around the small size of the Eckart E3 Hydraulic Rotary Actuator.

Over time, some customers have seen the advantage of upgrading their davits to fully powered operation. Previously, this required MarQuipt to provide various models that differed substantially both visually and in design and construction.

MarQuipt saw an opportunity to optimize their designs and eliminate unnecessary components by integrating the Eckart E3 Hydraulic Rotary Actuators into their davits. Thanks to its space-efficient design, the actuators fit into the same enclosure housing components in non-powered rotation versions of the same davit. As a result, MarQuipt was able to simplify the provision of powered rotation to smaller davits and lower the overall cost for the customer.

“Because we could fit the rotary actuator inside our existing housing, we could reduce some costs and make that option to power rotary things more attractive,” Byrd elaborated.

To learn more about MarQuipt’s full line of davits and cranes and other equipment, visit marquipt.com.

Behind Eckart’s E3 Hydraulic Rotary Actuator

The Eckart E3 is a hydraulic rotary actuator specially constructed for mobile applications and can provide rotations of 180° or 360°. Despite its compact size, it can deliver impressive torque, reaching up to 3,600 Nm (31,862 lbf-in) at an operating pressure up to 210 bar (3,045 psi).

Another key feature is its 4-point bearing, which is designed to handle side loads and multi-directional forces. This is particularly useful in applications subjected to high forces and continuous movement.

“Oftentimes, applications seem simple, but when you think about the application such as ones experience by davits and cranes in their natural environment, where saltwater environments are coupled with the motion of the boat, the forces acting on components can change suddenly. Eckart actuators excel in demanding environments due to their integrated 4-point bearings and internal corrosion protection, amongst other things,” commented Ben Hunger, President of IC-Fluid Power.

Like all Eckart actuators, the E3 utilizes the helical spline and gear principle. This design not only contributes to its compact size but assures a steady and low-wiggle working platform. The combination of carefully engineered threads and ball bearings with the absence of bi-directional seals leaves a stable platform with low backlash.

If you are interested in learning more about the Eckart E3 rotary actuator, visit them here.