Hydraulic Cylinders — Carbon Hybrid

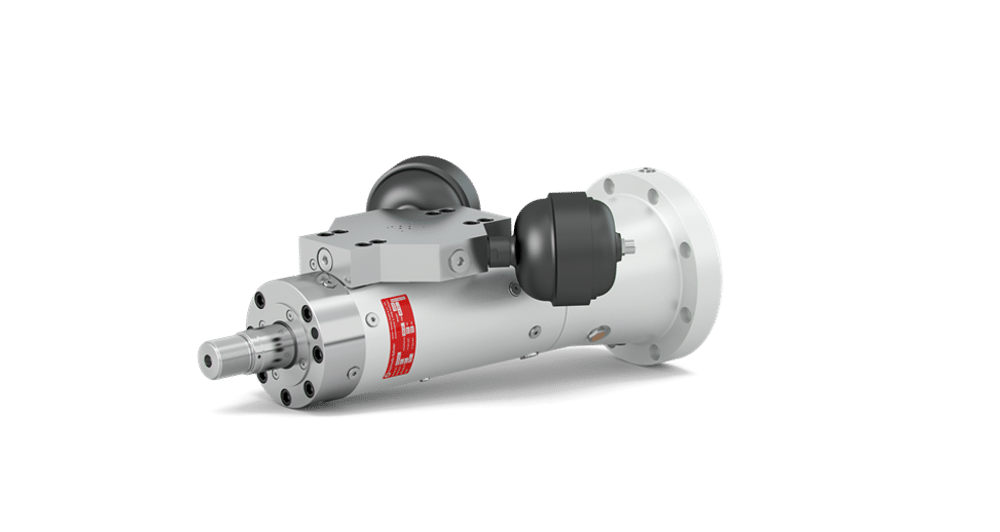

MARK carbon hybrid cylinders are the best of both worlds. Classic, high-strength metal (such as aluminum or steel) combined with lightweight, high-performance carbon fiber (CFRP).

Advantages at a Glance:

What does carbon hybrid mean?

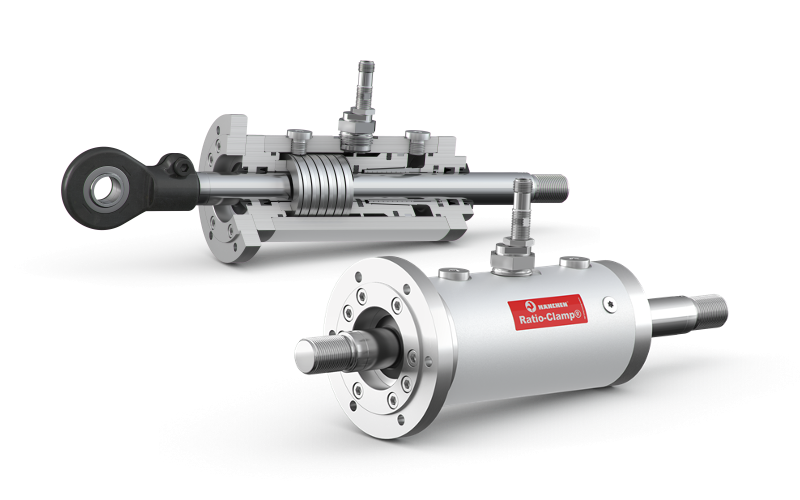

Precision-manufactured components such as pistons, rod guides, and cylinder bases are made of aluminum or steel for maximum resilience and durability. The inner tube, or the liner, is made of extremely thin steel (for example, on a micro-cylinder, the liner is only 0.4 mm thick), ensuring optimum tightness and precise sealing clearance.

The carbon hybrid comes from the fact that all cylinder parts are fully wrapped in carbon fiber. This carbon wrap is the only thing that connects the end pieces, such as the rod guide and cylinder base, and thus means optimal functioning of the cylinder. The carbon fiber is the structural connector, as opposed to welding, gluing or threading.

Why carbon?

Where Carbon Hybrid Cylinders make a difference

Because our carbon fiber cylinders are up to 70% lighter than traditional steel cylinders, using these components reduces energy consumption leading to measurable cost savings over time.

Below are some areas where our light-weight construction can really make a difference:

|

Application |

Where carbon fiber makes a difference |

How it makes a difference |

|

Lifting platforms |

Load moment |

Reducing weight allows the platform to lift more or lift more safely, because the structure needs to support less self-weight |

|

Transportation |

Deadweight |

Reducing deadweight increases potential payload capacity, reduces fuel usage, and improves efficiency |

|

Agricultural technology |

Load moment, corrosion |

Lighter components improve load moments on AG machinery, and because carbon fiber does not corrode, these cylinders are strong in this environment where moisture, dirt, and chemicals are prevalent |

|

Maritime |

Weight, corrosion |

Lightweight components improve stability and efficiency, while corrosion resistance is critical due to saltwater environments |

|

Exoskeletons, tools |

Micro-cylinders |

Our small, lightweight micro-cylinders are optimal in wearable exoskeletons or handheld tools, where low weight is essential for ergonomics and mobility |

|

E-mobility |

Weight reduction |

In electric vehicles, every kilogram saved increases range and efficiency, making lightweight components highly valuable |

|

Rescue cylinders |

Weight |

Lightweight, powerful cylinders make rescue tools easier to handle for emergency responders, improving speed and safety during operations |

MARK LIGHT is a supplier and hydraulic cylinder manufacturer for various applications including maritime, agricultural, mobility, and transport.