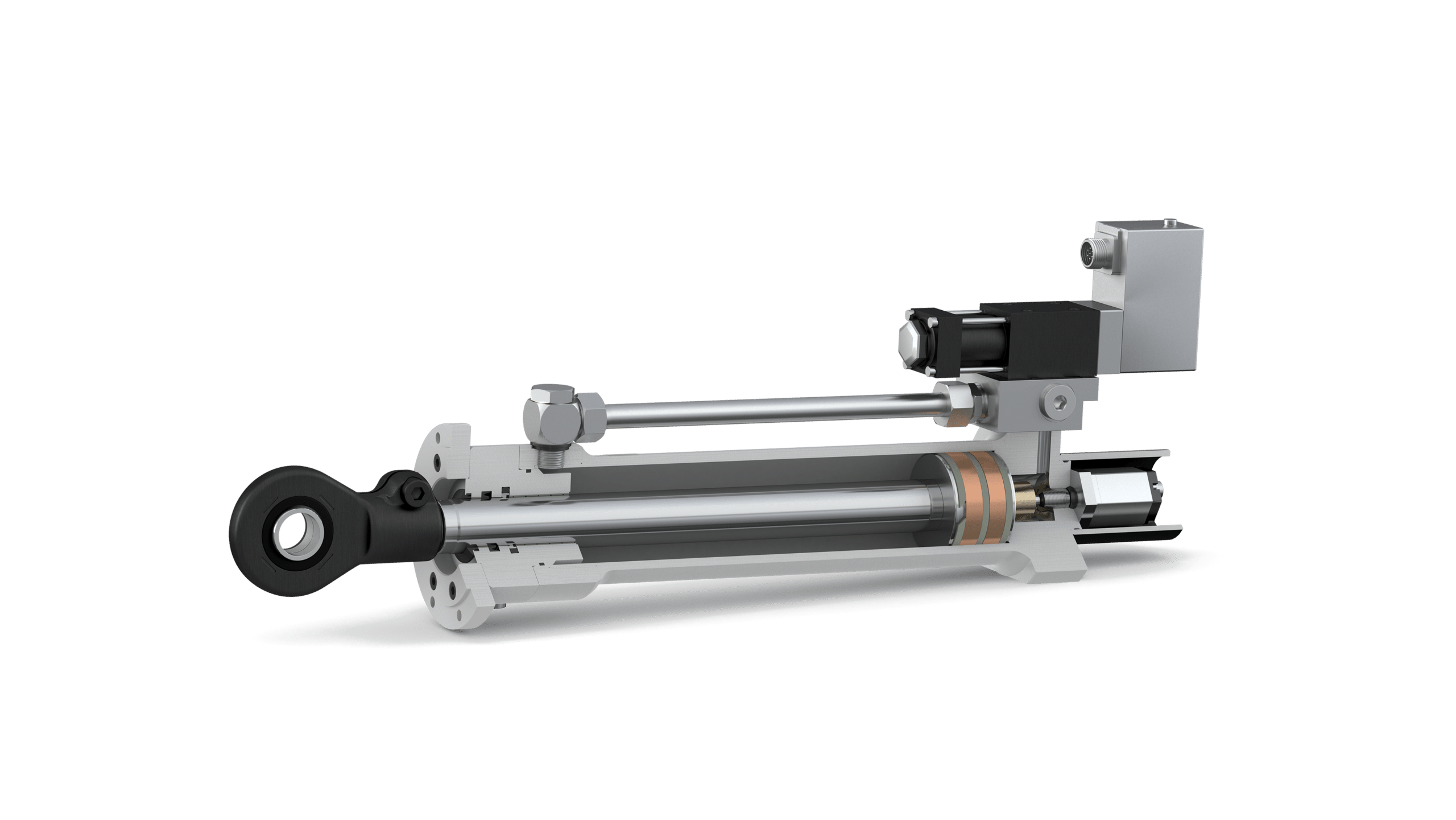

Hydraulic Cylinder Customizations

Any hydraulic cylinder design is possible with our extensive network of cylinder manufacturers. Every part of the cylinder can be customized including the material, type, medium, size, sealing, rod coating, mounting, ports, sensors, paint, cushioning, and load-holding options.

Generations of European Craftsmanship and Manufacturing

Anyone can sell you a part. As a distributor, we offer more than just cylinders.

Our roots run deep in hydraulic manufacturing. Our President, Ben Hunger, comes from the family business behind some of the world’s largest hydraulic cylinders. The founder of IC-Fluid Power, Armin Hunger, established the company to bring German precision and quality to the U.S. market. He built strong, lasting partnerships with European manufacturers, many of whom we still work with today. Through these connections, we provide access to European partners with over 100 years of expertise in premium cylinder manufacturing.

The right material determines the cylinder’s strength and lifespan. Choose from standard steels for general use, stainless steels for corrosion resistance, or lightweight alternatives like aluminum and carbon hybrids for mobile or specialized applications.

This is just a sampling of the common materials we use, but any specialty material is possible.

|

Material |

Types |

Common Examples |

|

Standard Steels |

Alloy steel |

AISI 1026, AISI 1045 |

|

Stainless Steels |

Austenitic steel |

AISI 304, AISI 306 |

|

Specialty Steels |

High strength, low-alloy steels; |

ASTM 4140, ASTM 1045, ASTM 4135 |

|

Non-ferrous |

Aluminum, Carbon fiber hybrid* |

– |

*The main body is made of carbon fiber with the remaining components made from steel, such as the listed steels above.

Choose a single-rod style for standard linear motion, a double-rod style for equal force in both directions, or a telescopic version when space is limited but stroke length is long. Tie-rod and welded cylinders differ in how they’re built. (Tie rods use long threaded rods to essentially sandwich the cylinders body together, while on welded cylinders the body components are welded together.)

|

Cylinder Type |

Best Used For… |

Application Example |

|

Single rod |

Standard linear motion, force in one direction |

General equipment |

|

Double rod |

Balanced force in both directions |

Test rigs, medium to highly dynamic applications |

|

Telescopic |

Long strokes |

Dump trucks, mobile lifting |

|

Tie rod |

Modular builds, low cost |

Factory automation, light to medium duty applications |

|

Welded |

High pressure, durability, rigidity |

Industrial, heavy-duty applications; and mobile |

Single or Double-Acting Cylinders

Hydraulic cylinders are available as single or double-acting:

- Single-acting cylinders use hydraulic fluid for movement in one direction that returns by gravity via dead weight or a spring.

- Useful when automation return is needed for safety if pressure is lost

- Standard applications

- Double-acting cylinders use hydraulic fluid in both directions.

- Useful when you need both forces to be equal

- High speeds and high frequency applications

- Useful for when a load needs to be attached to both cylinder ends (rare)

We offer a wide range of media for applications, selected based on the required viscosity, thermal stability, oxidation resistance, lubricity, and water tolerance.

This is just a sampling of the common medium we use, but any medium can be requested.

|

Mediums |

Medium Description |

Common Types or Examples |

|

Pneumatic |

Compressible gases common in fast, lightweight actuation applications |

Air, nitrogen, carbon dioxide |

|

Mineral oils |

Standard fluids with additives for anti-wear, oxidation, shock resistance, etc. |

H, HL, HLP, HLPD, HVLP, HLVPD, HH, HM, HR HV, HS, HG |

|

Fire-resistant fluids |

Water-based fluids (water-glycol or emulsions) and synthetic fluids common for flammable jobs (metalworking, mining, and foundry) |

HFAE, HFAS, HFB, HFC, HFDR, HFDU |

|

Biodegradable oils |

Synthetic esters, plant oils, or polyglycols common for agriculture, forestry, and sensitive ecosystems |

HTEG, HEES, HEPR, AND HEPG |

|

Specialty fluids |

Application-specific fluids, unique requirements for extreme temperatures and industry standards (military, aviation, automotive, etc.) |

Skydrol (aviation), MIL-H (military), DOT brake fluids (automotive), silicone oils |

Cylinder Sizes for Every Applications

Our hydraulic cylinders cover a full spectrum of sizes, from compact actuators to massive industrial units. With bore sizes ranging from 0.5 inches to 144 inches, there are virtually no size limitations we can’t handle.

Tell us about your application, and we will help you find the perfect seal. With over 60 sealing configuration types, IC-Fluid Power can provide any solution for your application. We make patented and standard seals for low friction, side loading, high pressures, rotation, fast/slow movement, stroke amplitude, and medium compatibility.

IC-Fluid Power’s Extensive Sealing Portfolio and Capabilities

- Unique catalog of 9 patented sealing and guiding mechanisms, plus 50+ standard and specialty solutions

- European-made industrial sealing capabilities

- Sealing solutions adaptable to your operation conditions (pressure, temperature, fluid type, dynamic requirements)

- Wide material selection including polyurethane, NBR, HNBR, Viton, bronze-filled PTFE, virgin PTFE, polyacetal, and more

- Special coatings and advanced composite design for harsh environments

Popular Choices for Patented Sealing Solutions

1. Servofloat® seal for low friction and high side loads

For testing and simulation, we offer over 12 different combinations for achieving low stiction and stick slip. One popular option for dynamic tests that require near frictionless movement is the patented Servofloat® seal. This works using a floating-gap principle to eliminate stick-slip. It enables extremely smooth oscillations at frequencies up to several hundred hertz, a key benefit for servo-drive applications.

See range of seals for testing and simulation.

2. GD1000K® for reliable sealing and guidance for heavy-duty conditions

The GD1000K® is a piston seal made for heavy-duty industrial and construction applications. It guides the piston and keeps it sealed using a bronze-filled PTFE slide ring and NBR energizing element. It maintains proper sealing even at zero pressure and prevents metal-to-metal contact under heavy side loads. The combined bearing and sealing give double-acting cylinders improved structural rigidity.

Standard Sealing Options

Not every application needs a specialty seal. Standard sealing options offer high performance for most cylinders. A common setup uses a lip seal together with a wiper ring to keep contaminants out and maintain sealing integrity. Static seals stop leakage at fixed interfaces, while dynamic seals control fluid between moving parts such as the piston and rod.

Dynamic Seals

|

Element / Seal Location |

Common Types / Examples |

|

Piston seals |

U-cup seals, T-seals, rectangular seals with elastomer, PTFE-backed seals, throttle gap seals, V-packings |

|

Rod seals |

Lip seals, U-cup seals, fabric-reinforced rubber seals, PTFE composite seals, polyurethane seals with O-ring energizers, V-packings |

|

Wiper seals |

Rubber scrapers, polyurethane wipers |

|

Buffer seals |

Polyurethane or rubber buffer rings |

|

Guiding systems |

PTFE rings, composite guide rings, metallic guides |

Static Seals

|

Element / Seal Location |

Common Types / Examples |

|

O-rings |

Nitrile (NBR), FKM, EPDM O-rings |

|

Backup/support rings |

Polyurethane buffer rings |

|

Static seal rings |

D-rings, flat gaskets |

Rod coatings protect piston rods from things like wear, corrosion, micro-scoring, and more to extend the service life of the cylinder. We offer standard surface treatments, such as classic nitriding and hard chrome plating. For large piston rods exposed to abrasive conditions, we also offer specialized coatings well suited for hydromechanical, chemical, offshore, and subsea environments.

|

Corrosion Protection |

Coating Type |

Coating Technology |

Best used for… |

|

Standard |

Nitriding |

Hardens the surface by diffusing nitrogen into the steel to improve wear and corrosion resistance |

General machine and industrial applications |

|

Standard |

Hard chrome plating |

Basic coating carried out by electroplating in single or multiple layers |

General machine and industrial applications |

|

Specialty |

Ceramic coating |

Thermal sprayed, metal-oxide finish using a nickel-chromium base with a ceramic top layer for hardness |

Machine and hydromechanical engineering, casting, printing, chemical; for large rods up to 59 in (1500 mm) Ø and 20 m long |

|

Specialty |

Plasma Transfer Arc (PTA) coating or laser cladding |

Welded stainless steel layers coating for offshore corrosive saltwater environment; protects carbon steel under submerged or splash zone conditions |

Offshore, marine, and subsea applications; |

We support a full range of cylinder mounting types from standard flange fittings to trunnion and pivot designs.

Cylinder Body Mounting

Each configuration below is described by movement range, alignment, and load type. Our cylinder manufacturers can adapt these mountings for special dimensions or retrofit use.

|

Cylinder Body |

Cylinder Body Image |

Degrees of Freedom |

Typical Force Direction |

|

Basic mounting |

|

Fixed |

Center load |

|

Threaded holes (cap side) |

|

Fixed |

Center load |

|

Side lugs (welded/bolted) |

|

Fixed |

Off-center load |

|

Circular flange (head/cap) |

|

Fixed |

Center |

|

Circular flange (cylinder body) |

|

Fixed |

Axial load |

|

Intermediate flange |

|

Fixed |

Axial load |

|

Pivot mount with spherical bearing |

|

2º of freedom |

Pivoting loads |

|

Pivot mount with plain eye |

|

1º of freedom |

Pivoting loads |

|

Intermediate trunnion |

|

1º of freedom |

Pivoting loads |

Piston Rod End Mounting

Piston rod ends differ in their fixation and mounting types.

Fixation Types

Each fixation type refers to the way the piston rod is mechanically connected or threaded for attachment to external components. The chosen fixation determines how forces are transmitted and how the rod end can be mounted.

|

Piston Rod Mounting Type |

Mounting Image |

|

Hook wrench |

|

|

Wrench flat (surface) |

|

|

Hexagon |

|

|

Without specified mounting |

|

Available Mounting Types

Each mounting type defines how the piston rod end is held during installation and maintenance for a secure connection.

|

Fixation Type |

Fixation Image |

Available Mounting Types |

|

External (male) thread |

|

Hook wrench, wrench flat, hexagon, without specified mounting type |

|

External (female) thread |

|

Hook wrench, without specified mounting type |

|

Flange rod end |

|

Hook wrench, without specified mounting type |

|

Smooth (plain) end |

|

Hook wrench, wrench flat, hexagon, without specified mounting type |

|

Hole circle |

|

Hook wrench, wrench flat, hexagon, without specified mounting type |

We offer a complete range of hydraulic port configurations and accessories. Our engineering team designs custom valve plates and adapter interfaces to match specific control valve standards, pressure ratings, and flow requirements.

Port Configurations for Screw Fittings

|

Head Side |

Cap Side | |

|

Ports |

SAE. NPT, metric, BSP |

SAE. NPT, metric, BSP |

|

Types |

Straight, tapered, ORFS, ORB, metal seal, flange |

Straight, tapered, ORFS, ORB, metal seal, flange |

|

Positions |

Radial, piped, mounting plate. custom |

Axial or radial, piped, flanged, mounting plate, custom |

Screw Fitting Accessories

An adapter, air filter, or test point can be installed on either side of the cylinder (left or right port). Test points include industry-standard M16x2 test points, which can be used for air bleeding, pressure testing, and other diagnostics.

Thread types available for air filters:

- G 1/8 (M10x1)

- G 1/4 (M12x1.5)

- G 3/8 (M18x1.5)

- G 1/2 (M22x1.5)

- G 3/4 (M27x2)

- G 1 (M33x2)

Mounting Plates for Valves or Threaded Fittings

We can build a mounting plate for direct installation of servo valves or directional control valves onto the cylinder head, minimizing pressure losses, and improving hydraulic response. The correct mounting surface is selected based on flow capacity, valve type, and application-specific requirements. Hydraulic oil connections are the same as the ports previously described.

The chart below features commonly used port types, but any can be made.

|

Mounting Surface |

ISO |

DIN |

Maximum Flow Rate |

Servo Valve Example |

|

– |

ISO 10372-01 |

– |

5 gpm (18 lpm) |

Domin S4 Pro, Moog 30, Moog 260, HR Textron 27A |

|

ISO 4401-03 |

DIN 24340-A6 |

10 gpm (40 lpm) |

NG 6, Domin S6 Pro |

|

ISO 4401-05 |

DIN 24340-A10 |

26 gpm (100 lpm) |

NG 10, Domin S10 Pro |

|

ISO 4401-05 with T2 |

DIN 24340-A10 with T2 |

42 gpm (160 lpm) |

NG 10, Domin S10 Pro |

|

ISO 10372-04 |

– |

15 gpm (60 lpm) |

Moog 76 |

|

ISO 10372-06 |

– |

66 gpm (250 lpm) |

Moog 72, Moog 791 |

How IC-Fluid Power’s Ports and Valve Plates Lead the Industry

- IC-Fluid Power’s hydraulic ports and accessories comply with ISO and DIN standards commonly used for servo valves and pressure control systems.

- Valve plate manufacturing follows proprietary standards from popular brands such as Domin, Moog, Bosch Rexroth, Atos, Parker, MTS, and HR Textron.

- For automotive and aerospace applications needing lightweight solutions, we can custom machine in high-strength steel or anodized aluminum.

- Our expertise in valve technology can be seen through our partnership with Domin Servo Valves, the most efficient and high-performing valves in today’s market. Learn more about Domin Servo Valves.

Sensors can be added for automation to measure and monitor critical changes in the system. These sensor integrations connect smoothly with automation platforms using Industry 4.0 standards. This allows for real-time data monitoring, predictive maintenance, and closed-loop control, which all contribute to better system reliability and performance.

Popular sensor options for traditional and Industry 4.0 compatible systems can be found in the list below:

- Proximity switches measure precise end-of-stroke position to detect stroke limits and confirm end position

- Position/stroke sensors measure piston rod position to provide feedback and enable closed-loop control

- Temperature sensors measure fluid, cylinder, or surface temperatures for monitoring and to prevent overheating

- Pressure sensors measure hydraulic pressure in chamber or line to prevent overloads

- Force transducers measure axial force to monitor the applied load and verify test parameters

As a primary distributor for many international cylinder manufacturers, IC-Fluid Power is capable of several different painting options from single acrylic coatings for standard cylinders to advanced multi-layer epoxies and urethanes made for offshore and military coatings.

Standard Options

- Cylinders can be left unpainted with or without temporary transportation and storage corrosion protection (VCI, wax, silane, phosphate, grease)

- Primer only (acrylic, epoxy, or other as specified)

- Base coatings use 1k synthetic epoxy or acrylic paints for general environmental resistance

Specialty Options

- Specialized coatings include robust 2K epoxy systems.* These offer high adhesion and chemical resistance suited for offshore, mining, and industrial conditions. This durable coating is used to withstand intensive mechanical and chemical stress while offering exceptional coverage and scratch resistance.

- Military-grade coatings meet specific defense or government requirements and are provided upon request.

- Offshore coatings use multi-layer epoxy or polyurethane systems to withstand saltwater exposure and harsh marine exposure.

*For customized cylinders made from Germany, our Hänchen cylinders are finished with a 2K polyurethane structural paint (silicone-free) in RAL 9006, white aluminum semi-gloss.

Cushioning is added to gradually slow the piston as it nears the end of its stroke, protecting the cylinder and connected equipment from impact damage and excessive shock loads.

Our hydraulic cylinders can be equipped with standard or advanced cushioning systems with customized orifices.

IC-Fluid Power’s Advanced End-Cushioning Options

Cushioning can be either added in the cap/head and the bottom. The following characteristics that can be customized:

- Cushion spear length

- Needle valve size and adjustment per flow rate

- Cavity shape and size

- Cushion design (tapered or orifice)

- Cushioning profile (single stage or multi-stage with multiple adjustable needle valves, orifices, or other custom-led designs to meet application requirements)

- Cushion material

- Reverse stroke

- Check valve (bypass valve)

We offer rod-locks (Ratio Clamp®) as an optional feature for standard and custom hydraulic cylinders providing added security and functionality.

The Ratio Clamp® is a patented hydraulic clamping device that instantly locks piston rods or round rods, holding loads up to 2,000 kN. This device incorporates a spring force that clamps the rod securely in place without continuous energy, releasing only when hydraulic pressure is applied. Since these rod locks are mechanically locking and hydraulically unlocking, they also can be used as a safety device. This is an easy way to hold a cylinder in position indefinitely while not requiring any input from your HPU (saves money too!).