SERV-CLIP® HOT TAP CONNECTION

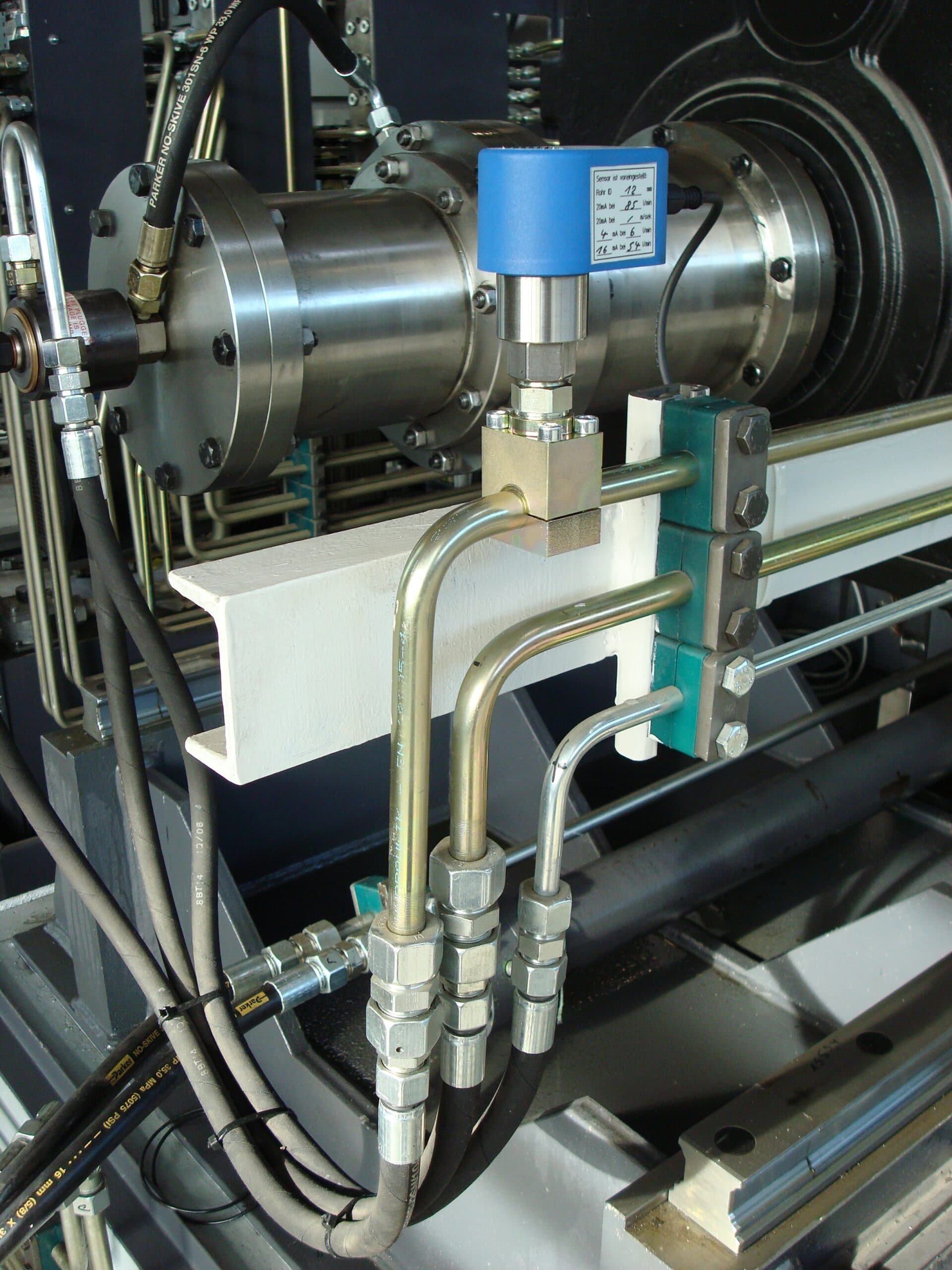

Serv-Clip® Hot Tap Connection

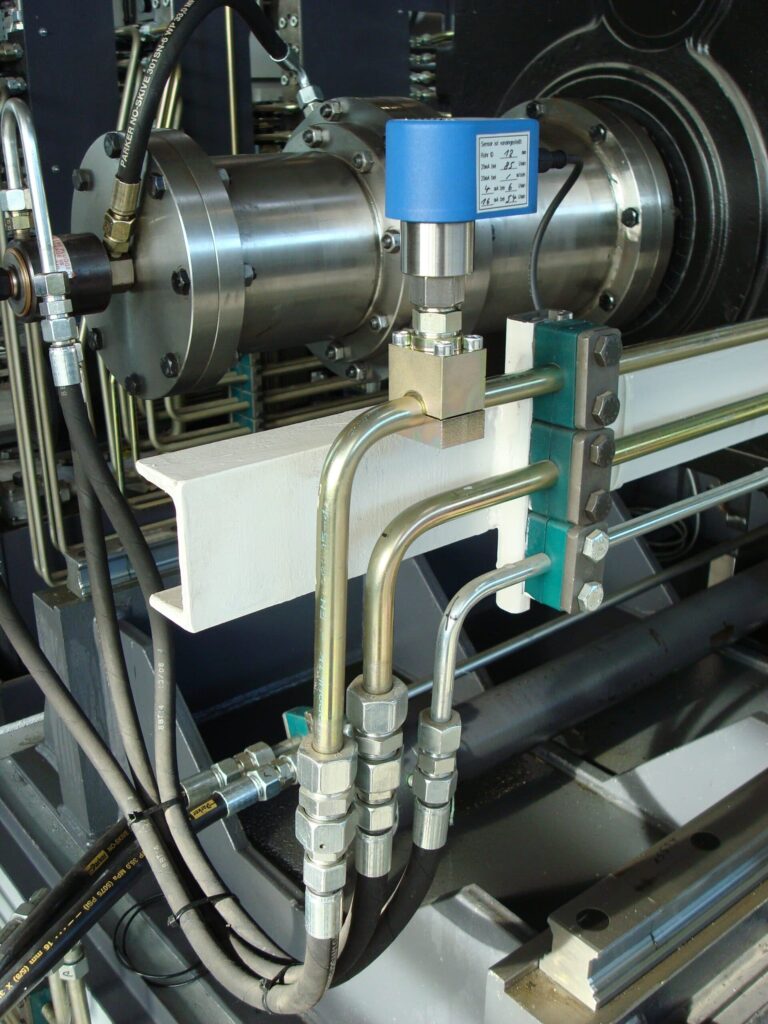

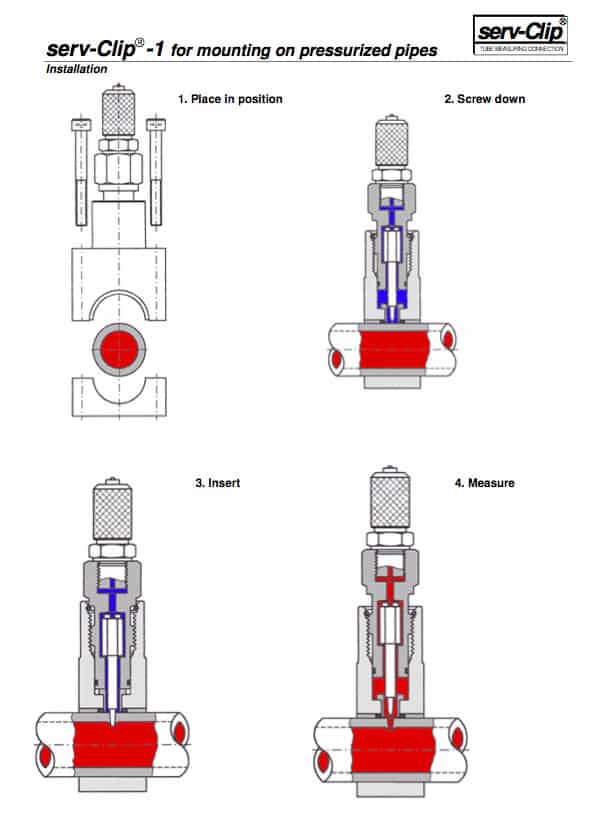

The Serv-Clip® tube measuring connection is used to add a test point on an existing hydraulic circuit within 3 minutes—no cutting of pipes, even if the system is pressurized to 9,100 psi (630 bar). Then carry out your measurements: pressure, flow rate, leakage, temperature, oil sampling or connect a variety of measuring devices.

Required tools for installation: 6mm allen wrench and jaw wrench SW22

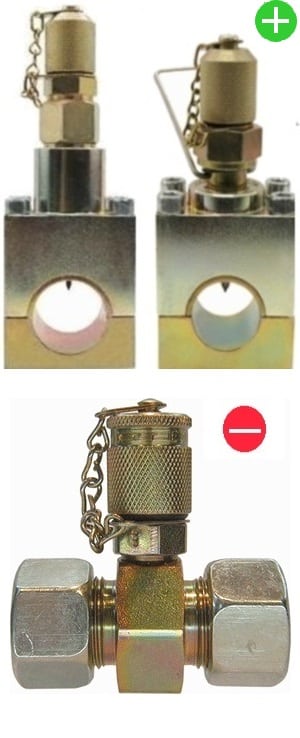

Models: Serv-Clip® Type 1 (Installation on pressurized pipes):

Used for sensors with G1/4″ thread

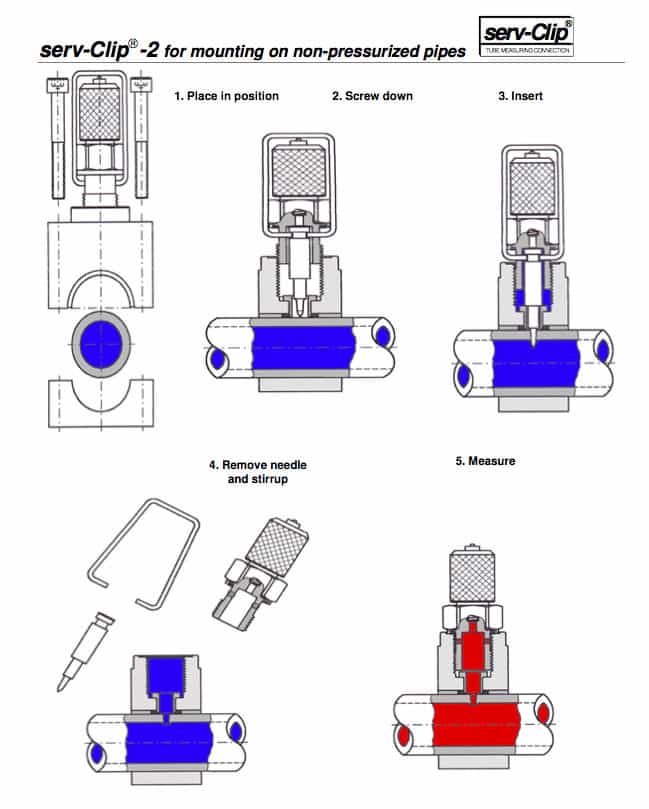

Serv-Clip® Type 2 (Installation on non-pressurized pipes):

Used for sensors with G3/8″ thread

Diameters Available:

The flow rate and leakage sensor functions through the calorimetric principle and can be installed with the Serv-Clip tube measuring connection Serv-Clip® (type 2) in 5 Minutes without cutting pipelines and only requiring the pressure of the hydraulic system to be removed while the needle is piercing the pipe or tube and while the sensor is being installed. The output signal is 4 to 20mA and is calibrated according to your requirements. With the Flow Rate Sensor (from 0.164 to 16.4 feet per second or from 0.05 to 5 meters per second). The sensors are available in stainless steel and plastic covers:

With the Leakage sensor (from 0.164 to 16.4 feet per second or from 0.05 to 5 meters per second):

Watch the following videos for a demonstration of how the Serv-Clip is installed and utilized.

Serv-Clip® is a supplier and Serv-Clip® Hot Tap Connection manufacturer for various applications including construction, mechanical, technological, and industrial.