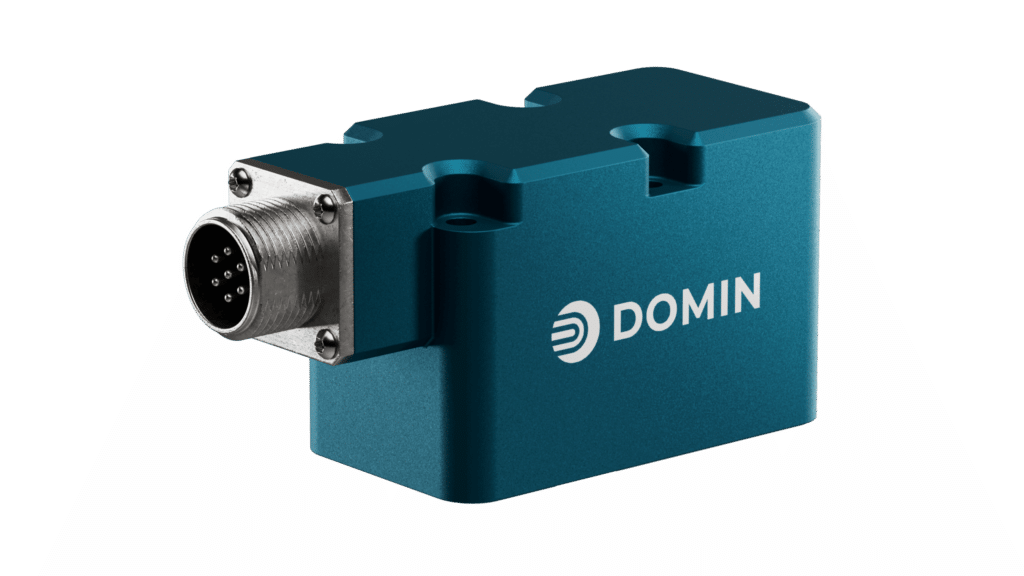

Hydraulic Servo Valves – S10 Pro

Unrivaled Performance and Efficiency

Unlock massive energy savings with the Domin S10 Pro series, the most efficient direct drive valve for flows ranging from 13 to 66 gpm (50 to 250 lpm).

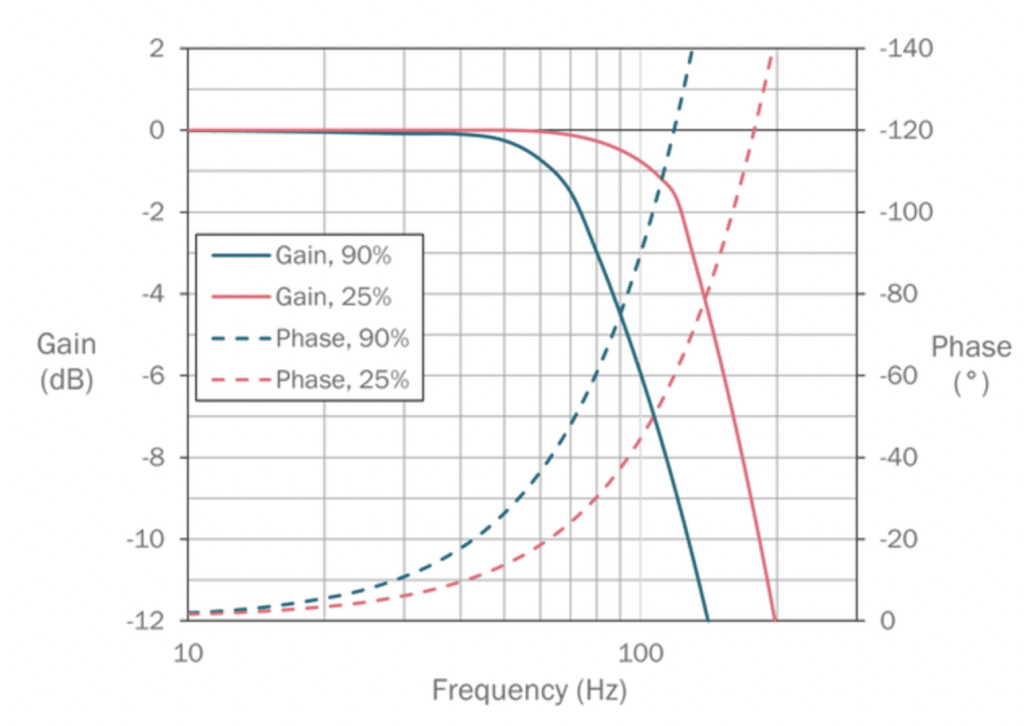

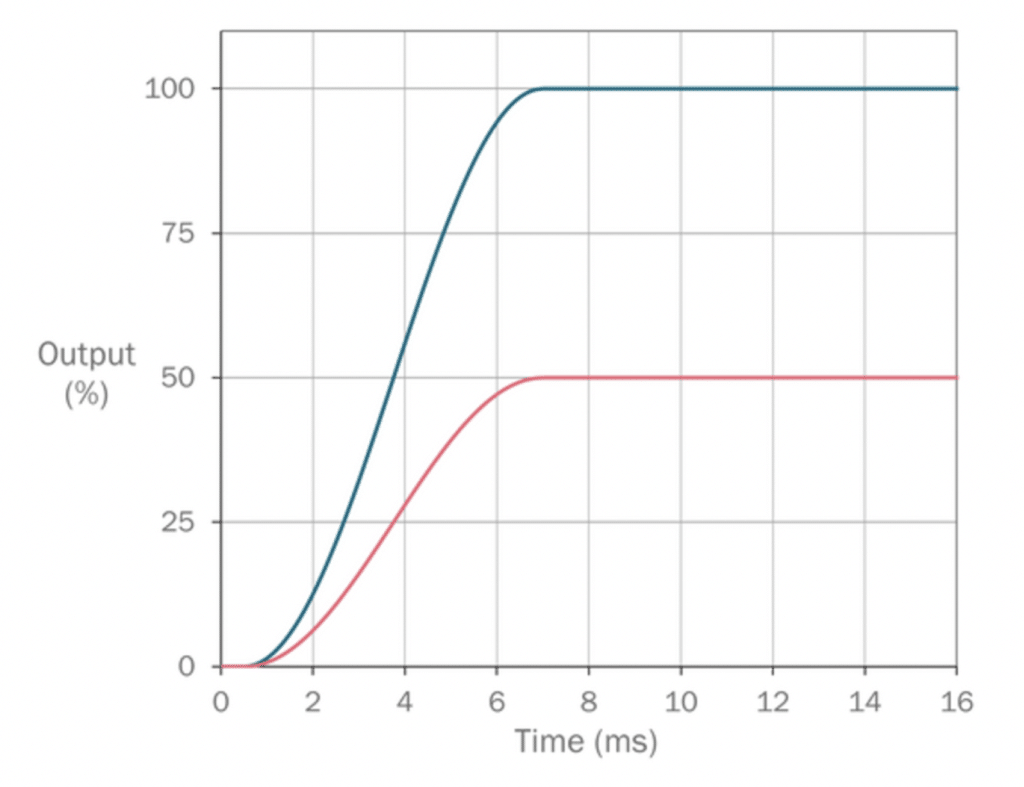

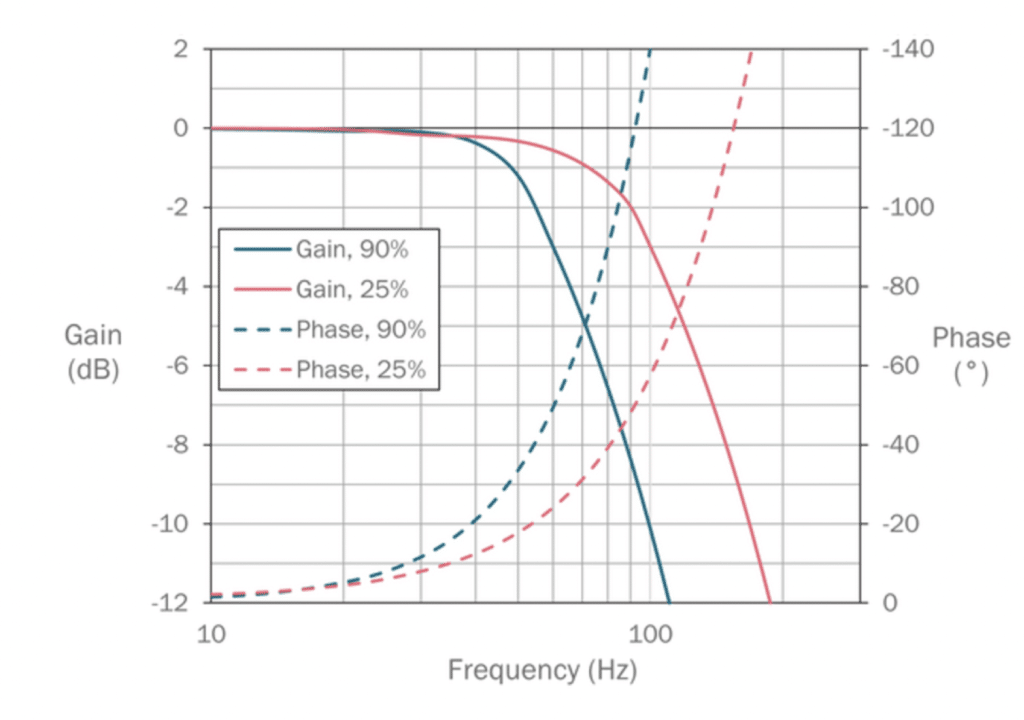

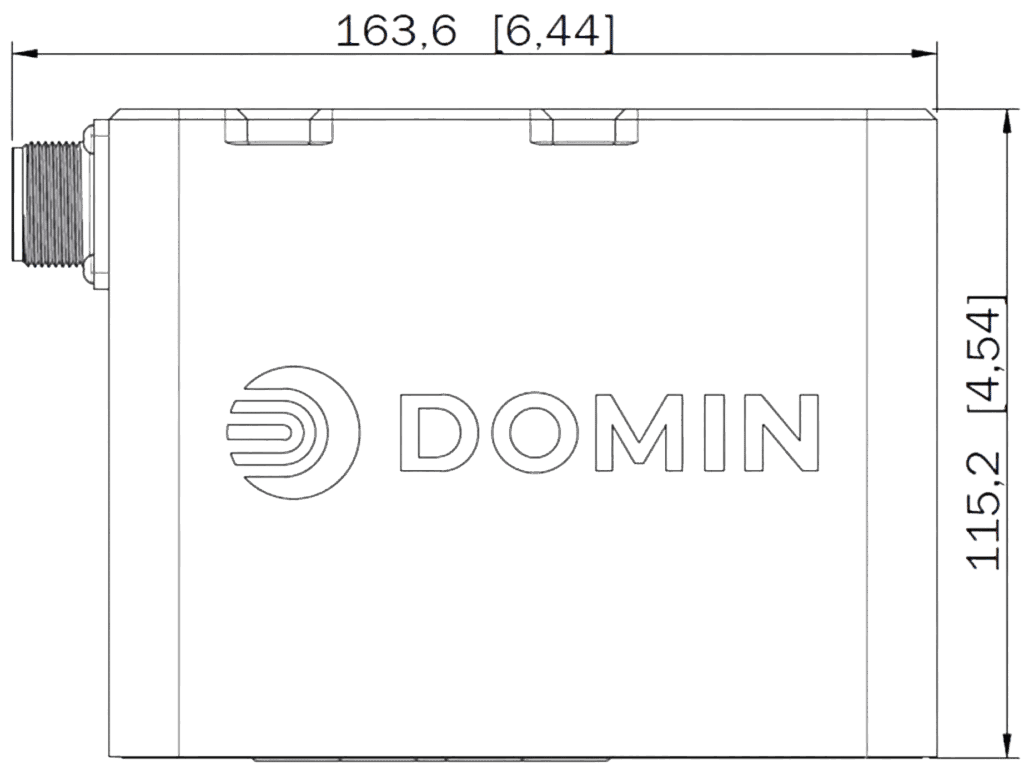

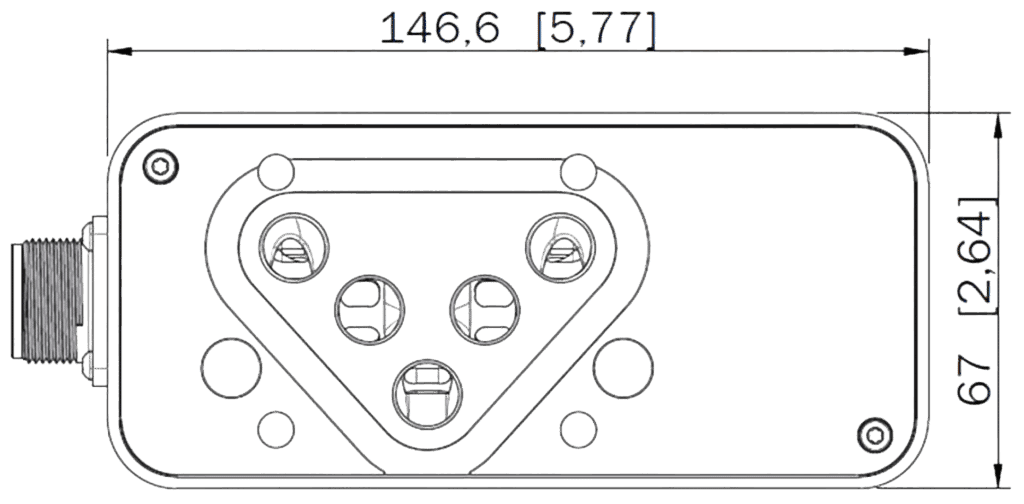

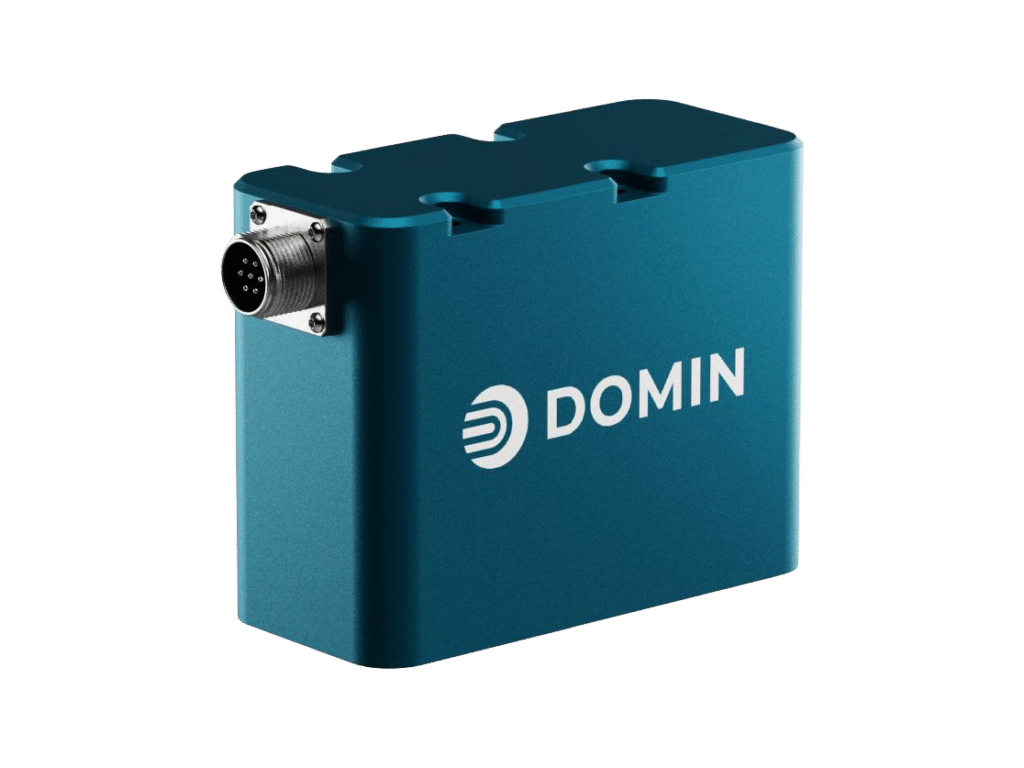

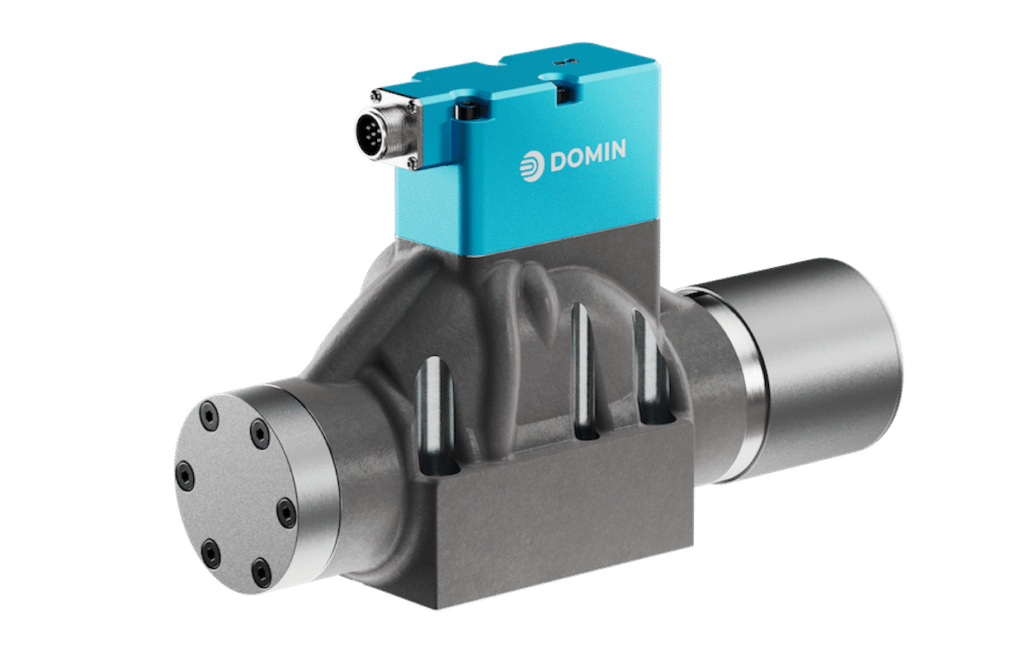

Designed to sustain high bandwidth operation at exceptional flows without compromising on operating pressures or duty cycles, the S10 Pro is the pinnacle of reliability and versatility. Where other servo proportional valves struggle with packaging size and weight, the S10 Pro rises above, offering a lighter and more compact alternative to traditional electrohydraulic servo valves.

Experience the difference with the Domin S10 Pro. Whether you’re dealing with high flows or demanding applications, its single-stage design ensures optimal performance every time.

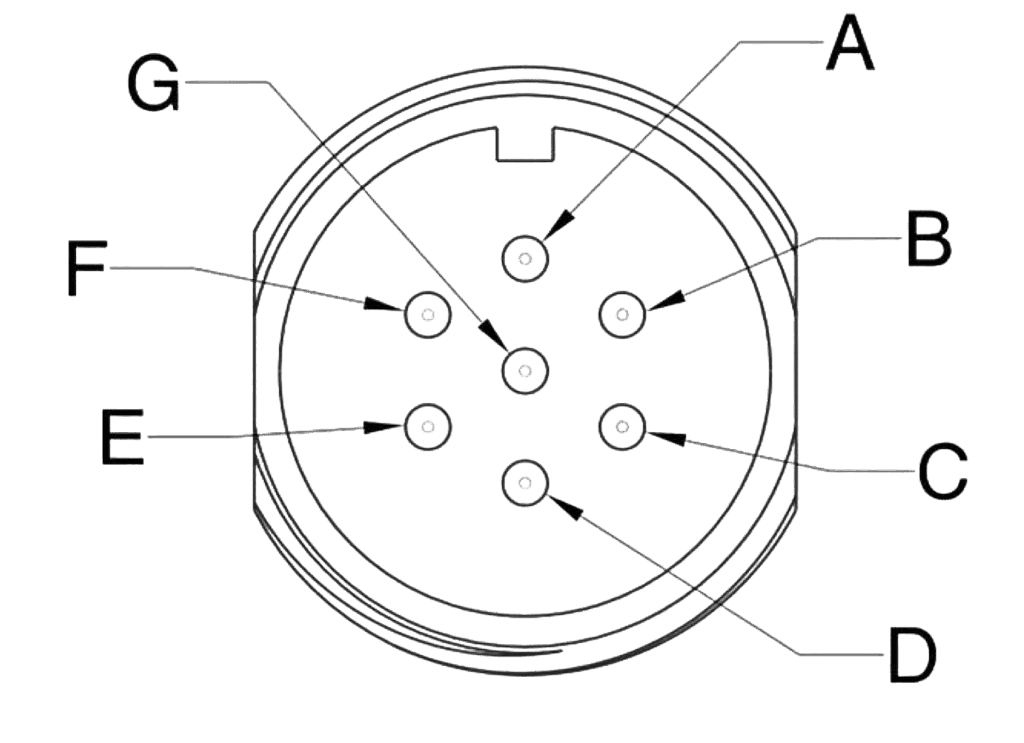

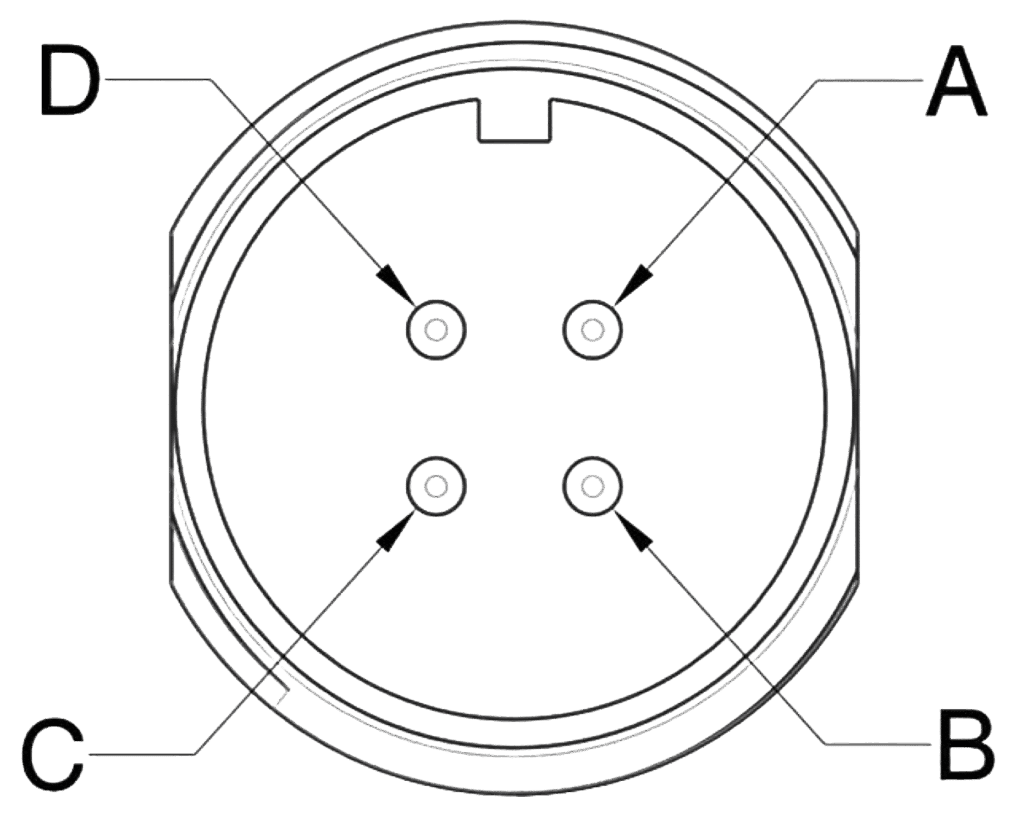

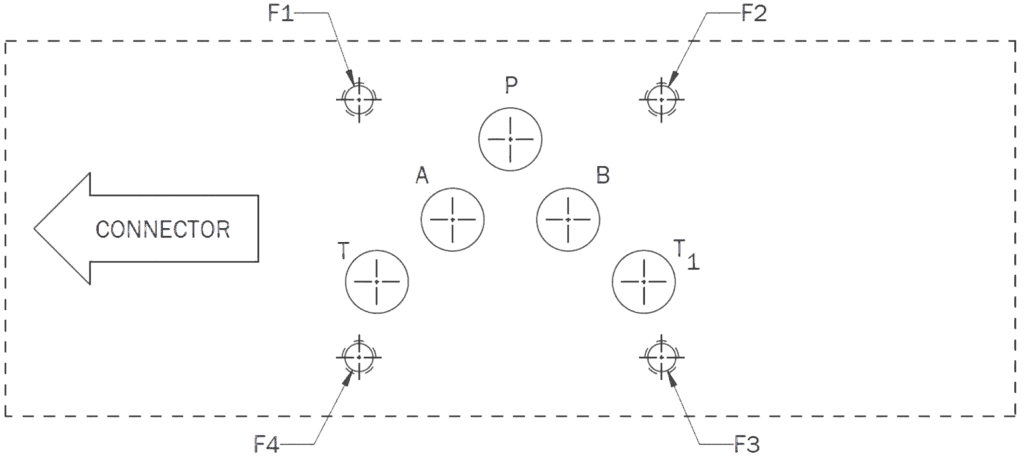

Available on NG10 port pattern as standard. S77 adaptors available.

Popular Upgrade Models:

Key Stats:

Key Features:

Standard Modification Options:

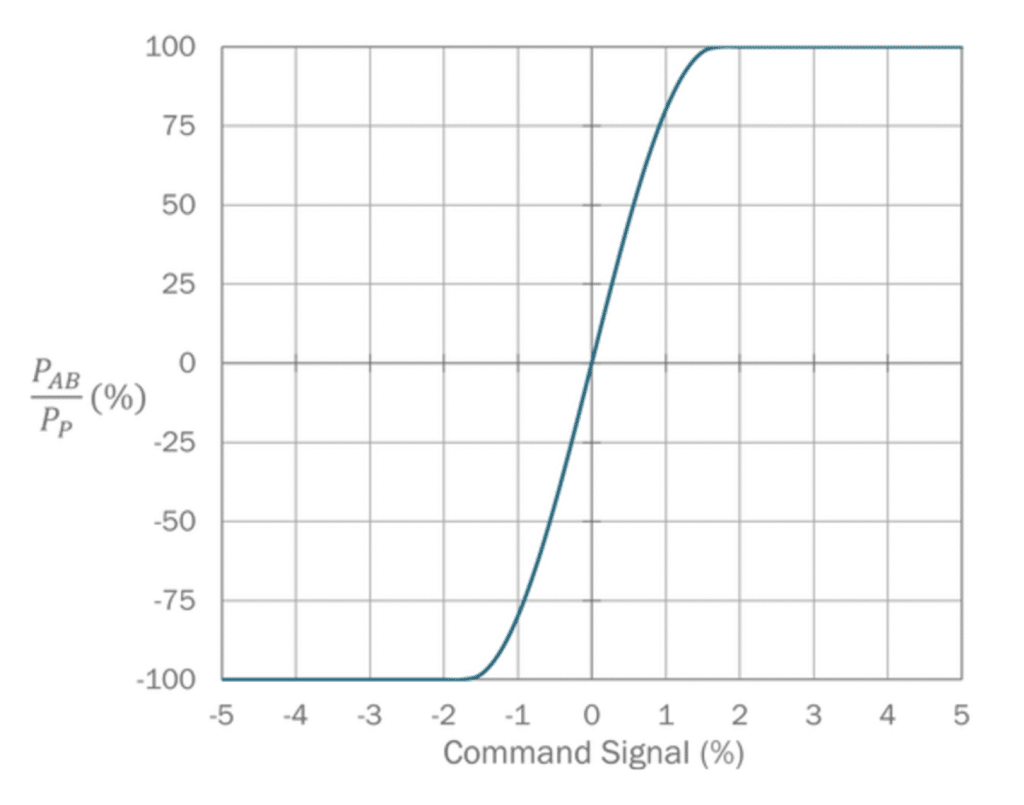

Technical Data:

Ordering Code

S10 Pro 1 2 3 4 5 6 7 8 9

Variants on Request

Domin is proud of their ability to offer tailored solutions that meet customers’ specific needs. If you require a non-standard configuration, or a bespoke modification, we are confident we can provide you with the best solution. Talk to us here and one of our team will respond as soon as possible.

Domin is a supplier and servo valve manufacturer for various applications including blow/injection molding, wood/timber machines, metal processing, die casting, hydraulic presses, and vibration equipment.