HYDRAULIC HOSES — LOW PRESSURE THERMOPLASTIC HOSES

Hydraulic Hoses — Low Pressure Thermoplastic Hoses

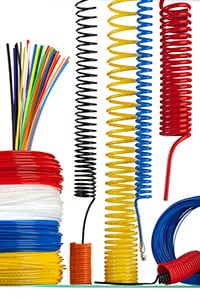

ZEC offers Low Pressure Theromplastic Hoses, for applications in the pneumatics field and in lubrication. They are manufactured in the various typologies in single, multiple or spiral version, in Rilsan PA11, Polyamide 12, Polyurethane, Hytrel, Polyethylene, Ptfe. ZEC hoses meet the main international regulations.

Product Features:

Reduced weight and size thanks to the use of raw materials of improved toughness and low specific weight

Excellent resistance to fatigue stress, alternating flexing and vibrations

Due to the low surface roughness of approximately 0.6 microns, Zec’s thermoplastic hoses achieve minimal head loss and increased flow rates

Extremely long lifespan thanks to the exceptional anti-aging qualities of the techno polymers used

Rilsan® Tubes:

ZEC Rilsan® tubes are in compliance with the European directives REACH (2006/1907/EC) and RoHS 2 (2011/65/EU).

Rilsan® HT Tube – new:

For all the applications that require thermoplastic flexible tubes for high working temperature ZEC RILSAN® HT provides a valid alternative to the traditional metal or PTFE tubing. ZEC RILSAN® HT is a thermoplastic tubing suitable for conveying hot fluids not water-based, and it is used in industrial and automotive field. The raw material used in this tubing is the Rilsan® HT, a special PolyPthalAmide (PPA) obtained from renewable sources. It is characterized by excellent chemical and mechanical properties, and a high resistance to the thermo-oxydative heat aging. This tubing has successfully passed all tests required by the DIN 73378 and ISO 76281 international standards.

Product Features:

ZEC RILSAN® HT thermoplastic tubes are an innovative solution for the industrial or automotive applications that require resistance to high temperatures, as alternative to the traditional metal or PTFE tubes. ZEC RILSAN® HT tube is suitable for conveying hot fluids (oils, fuels, air and refrigerant fluids) not water-based.

ZEC RILSAN® HT tubes have been developed using an innovative thermoplastic Bio-polymer called Rilsan® HT obtained from renewable sources. It is a PolyPhtalAmide (PPA) characterized by an excellent resistance to the thermo-oxydative heat aging. This material is Biobased up to 70% (see Fig. 1) and it favors the emissions reduction of carbon dioxide (CO2).

ZEC RILSAN® HT tube provides excellent thermoforming, good mechanical properties and abrasion resistance, together with a high resistance to chemicals and to aggressive environments. This tubing has successfully passed all tests required by the DIN 73378 and ISO 7628 international standards.

Working temperature of ZEC RILSAN® HT tubes is in the range -40°C to +150°C. For temperatures above ambient (23°C), it is necessary to calculate the corrected burst pressure using the correction factor obtained by means of diagram in Fig. 2.

Rilsan® T Tube:

ZEC RILSAN® T is a thermoplastic tubing particularly suitable for industrial pneumatics and developed using an innovative polymer: the Rilsan® T. Such raw material is a special PolyAmide (PA10.10) of green origin, obtained from renewable sources, alternative to technical polymers derived from hydrocarbons. ZEC RILSAN® T is a high quality tubing able to ensure excellent resistance to pressure, great flexibility and reduced bend radii. For all applications for fluids conveying, ZEC RILSAN® T tube also shows an excellent chemical resistance and a good resistance to heat. This tubing has successfully passed all tests required by the DIN 74324, DIN 73378 and ISO 76281 international standards.

Product Features:

ZEC RILSAN® T tubes are particularly suitable for industrial pneumatics, compressed air circuits and oil transfer.

These tubing have been developed using an innovative thermoplastic polymer, the Rilsan® T, a special BIO-PolyAmide (PA10.10) obtained from green renewable sources (see Fig. 1). This material provides an effective alternative to technical polymers derived from hydrocarbons and it favors the emissions reduction of carbon dioxide (CO2).

ZEC RILSAN® T tube provides excellent physical and mechanical properties, together with a good chemical resistance even with polyols, solvents, paints and compatible gas, in chemically aggressive environments. This tubing has successfully passed all tests required by the DIN 74324, DIN 73378 and ISO 7628 international standards.

Working temperature of ZEC RILSAN® T tubes is in the range -40°C to +100°C. For temperatures above ambient (23°C), it is necessary to calculate the corrected burst pressure using the correction factor obtained by means of diagram in Fig. 2.

Rilsan® HTR Tube:

ZEC HTR thermoplastic tube is widely used for years in industrial automation. This is a high quality product ideal for pneumatic applications, where it is required great reliability, good mechanical resistance and reduced bend radii. The use of a special Thermoplastic Polyester Elastomer (TPE or TEEE) allows to achieve an excellent compromise between features of flexibility and resistance to pressure.

Product Features:

ZEC HTR tubes are particularly suitable for industrial pneumatics, compressed air circuits and oil transfer.

Unlike traditional tubes made of thermoplastic flexible grade material, available on market today, ZEC HTR tubes do not contain plasticizers because the flexibility is guaranteed by their internal elastomeric molecular structure. Therefore, these tubes do not have the inconvenience of contamination by release of plasticizer resulting in tube stiffening.

Unlike traditional tubes made of thermoplastic flexible grade material, available on market today, ZEC HTR tubes do not contain plasticizers because the flexibility is guaranteed by their internal elastomeric molecular structure. Therefore, these tubes do not have the inconvenience of contamination by release of plasticizer resulting in tube stiffening.

At room temperature chemical resistance is good also with polar fluids, glycols, higher molecular weight alcohols, weak acids and bases.

Working temperature of ZEC HTR tubes is in the range -40°C to +100°C. For temperatures above ambient (23°C), it is necessary to calculate the corrected burst pressure using the correction factor obtained by means of diagram in Fig.1.

ZEC is a supplier and thermoplastic tubing and hoses manufacturer for various applications including construction, mechanical, technological, and industrial.