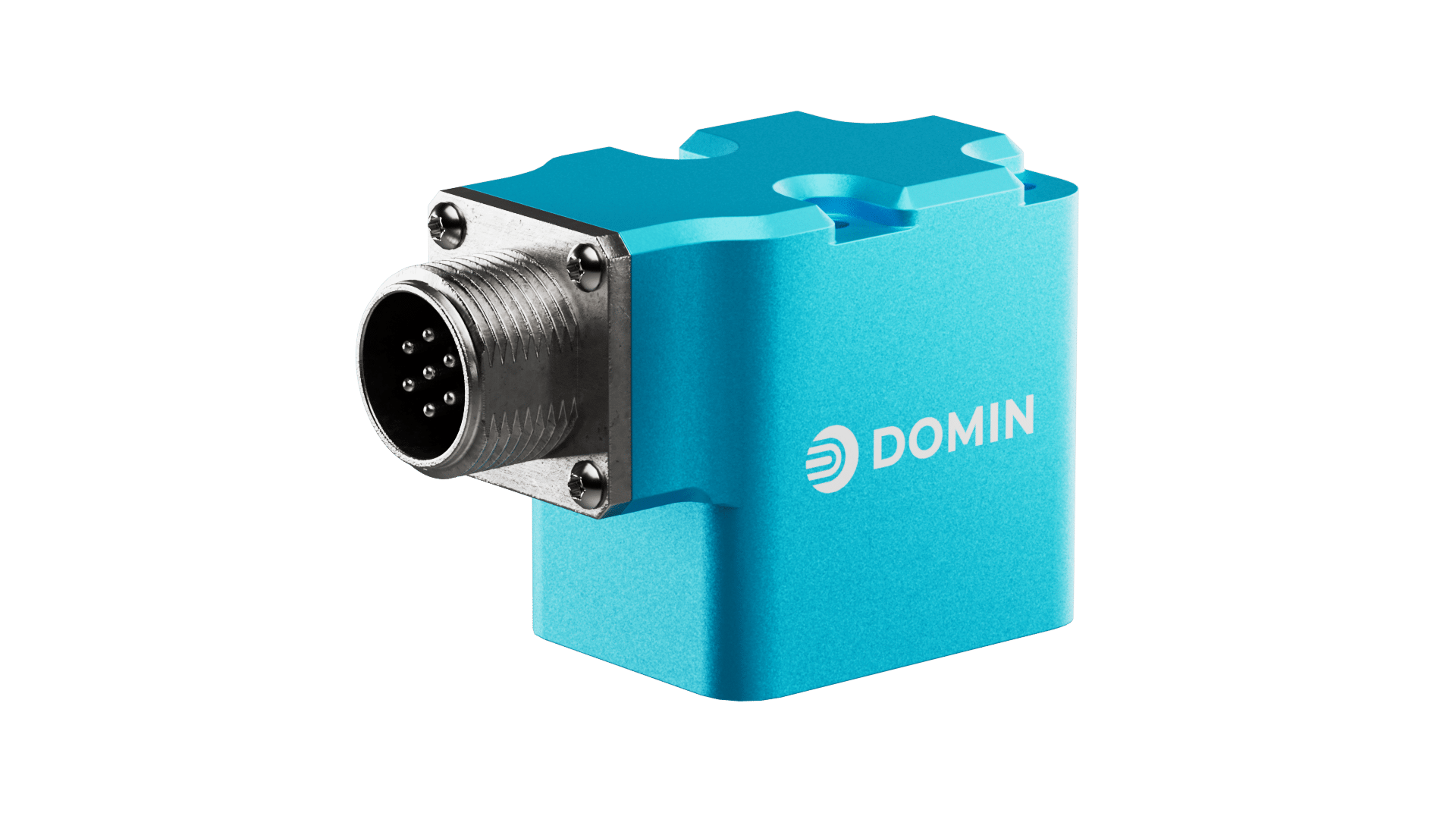

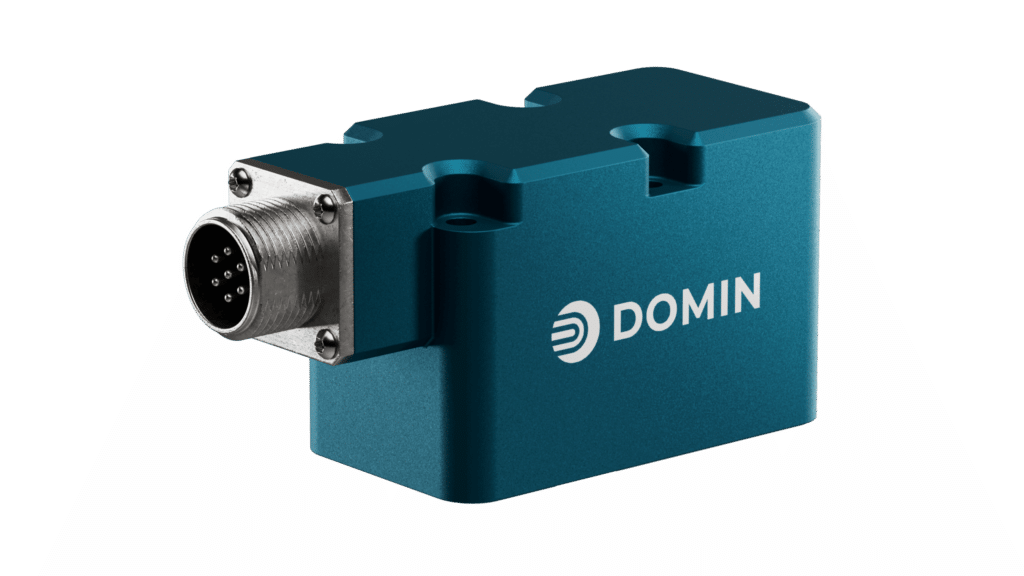

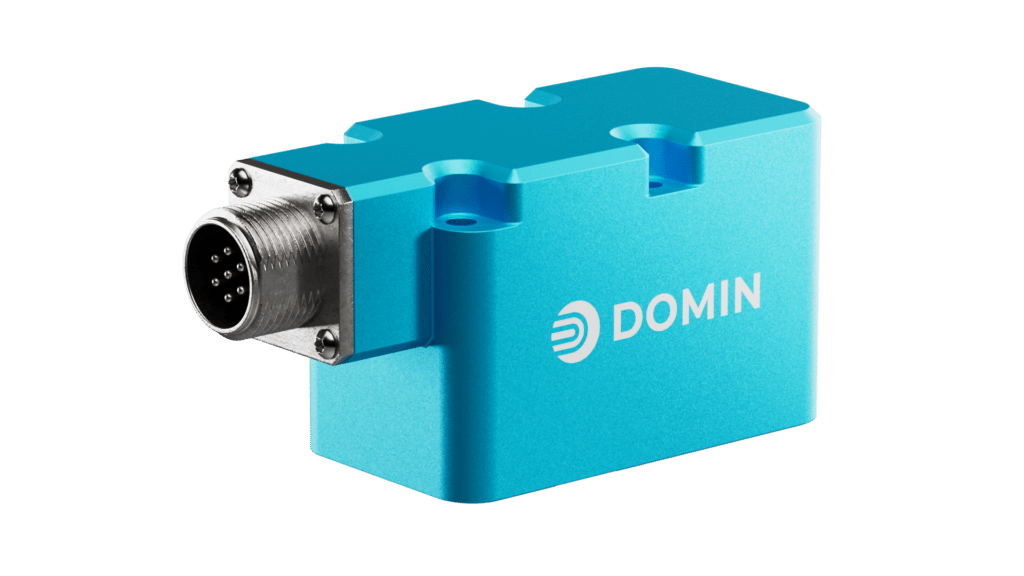

Hydraulic Servo Valves – S4 Pro

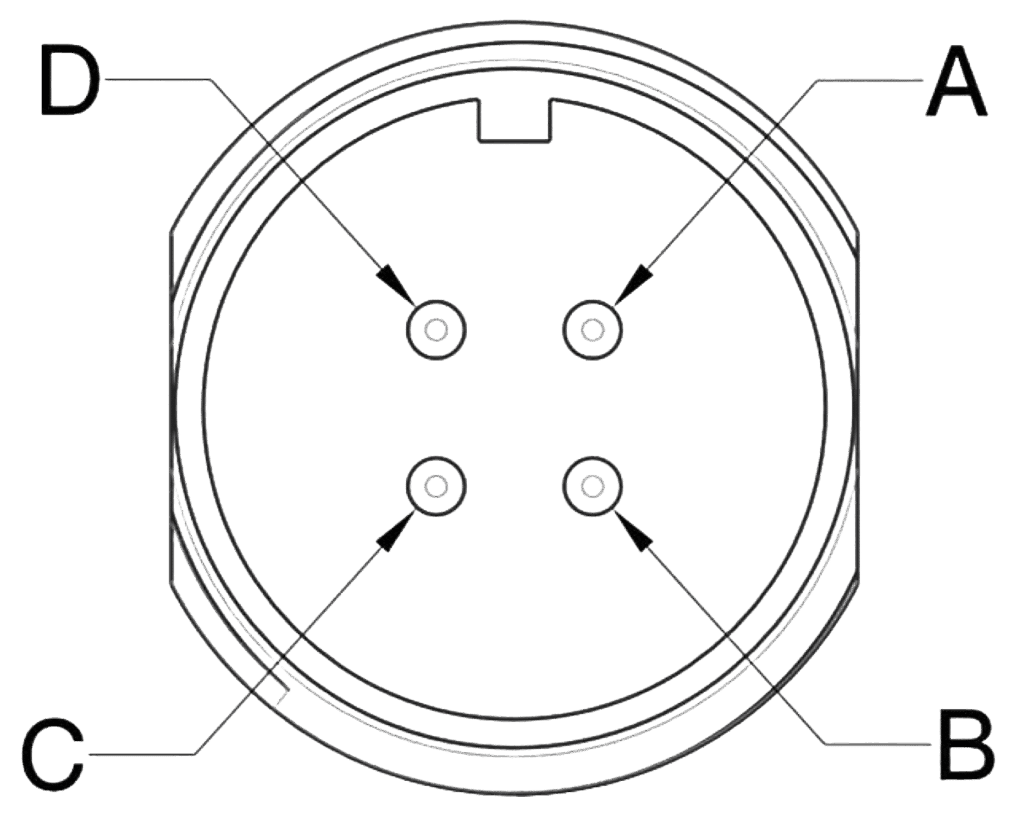

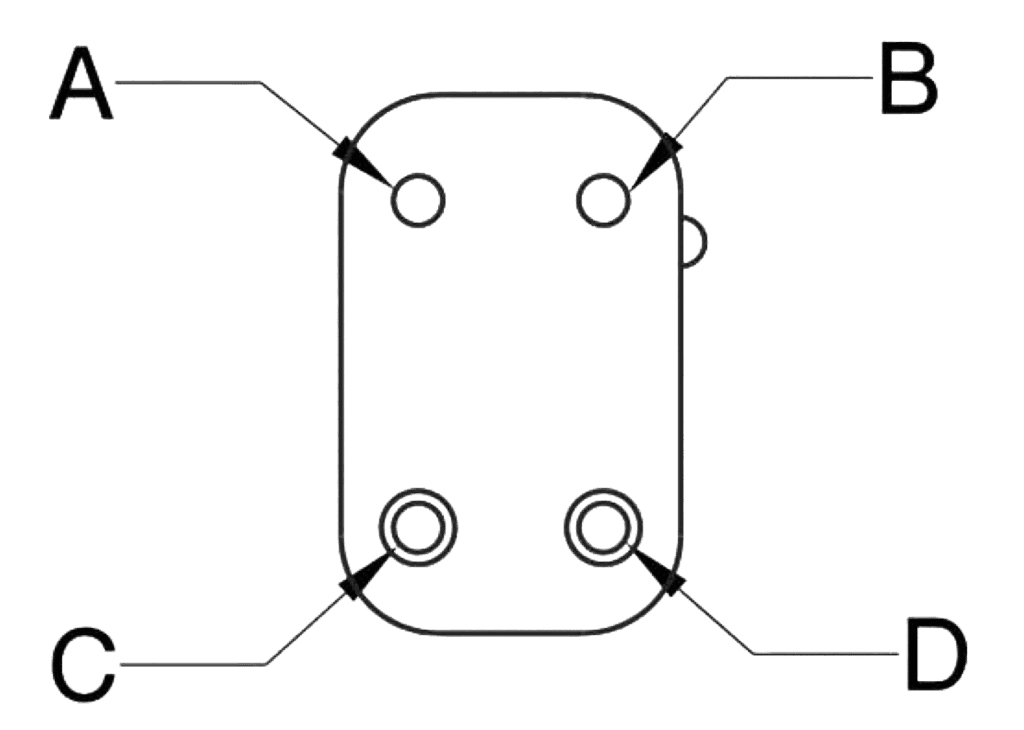

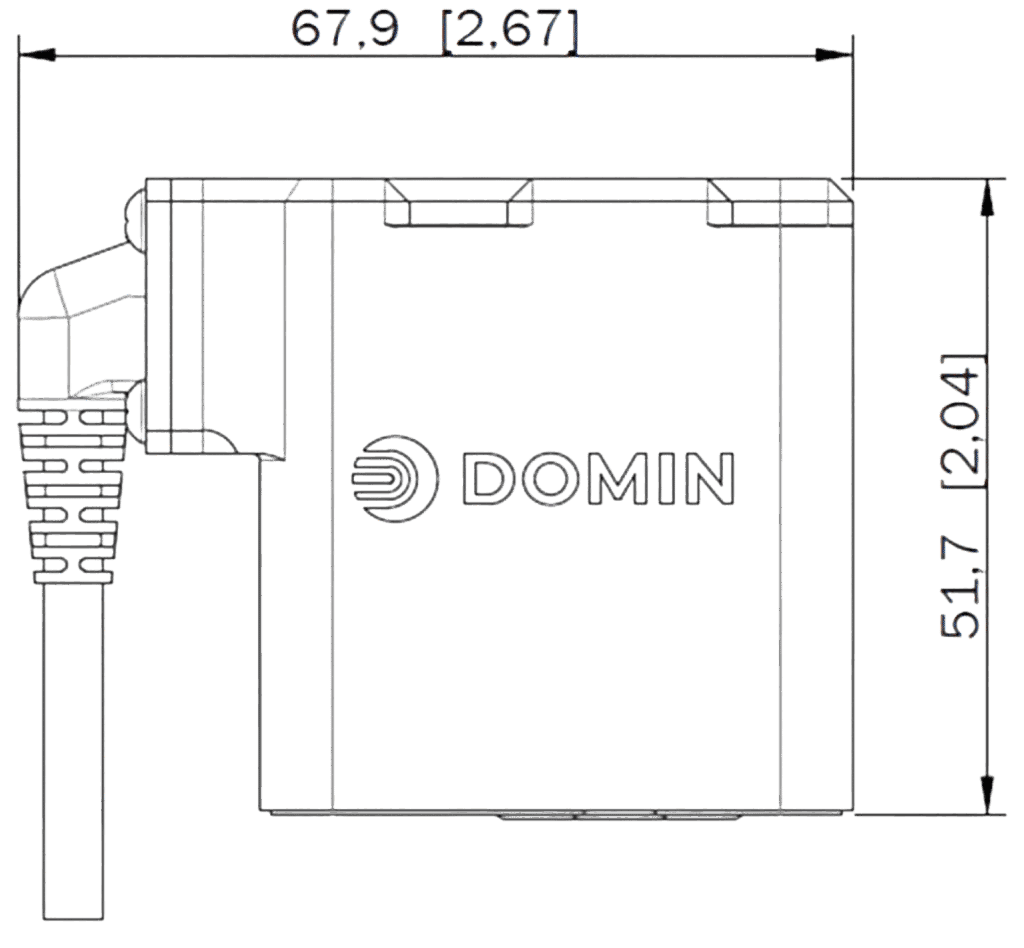

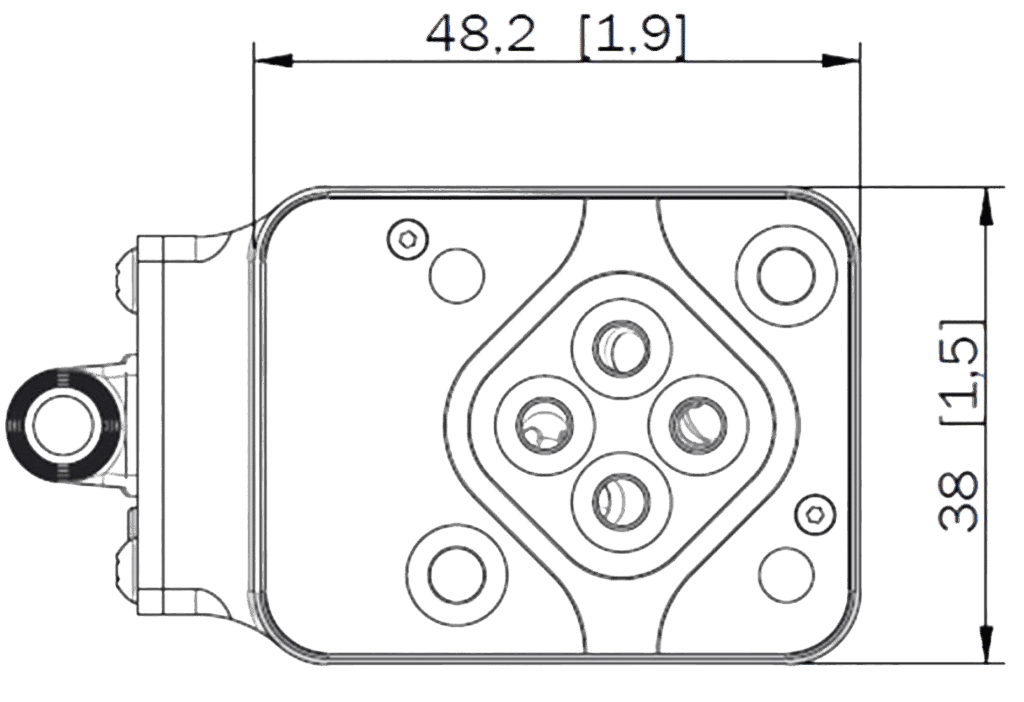

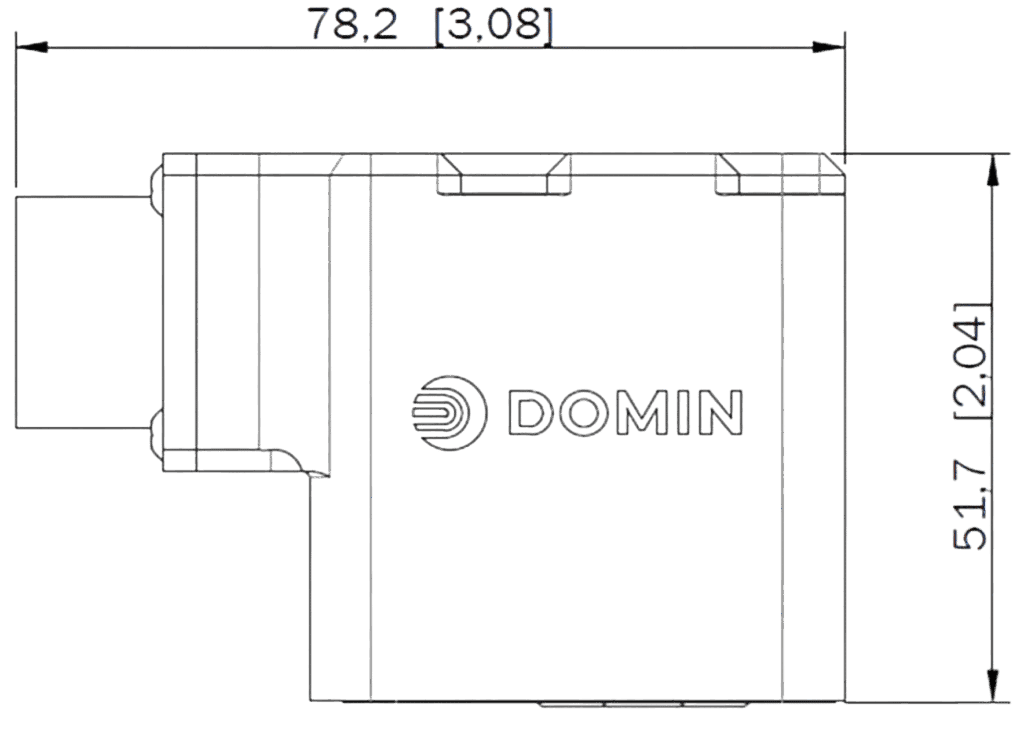

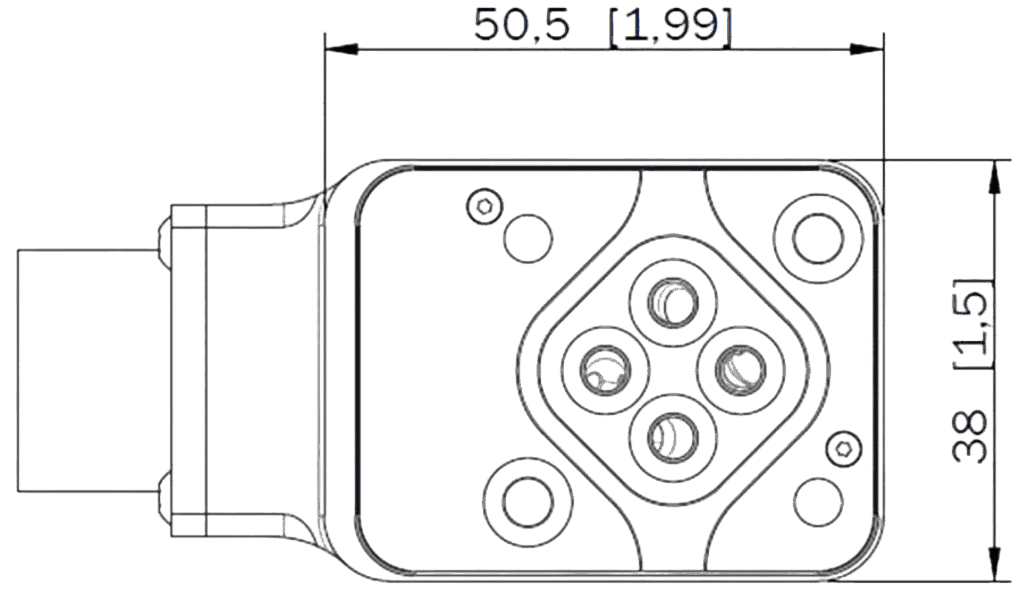

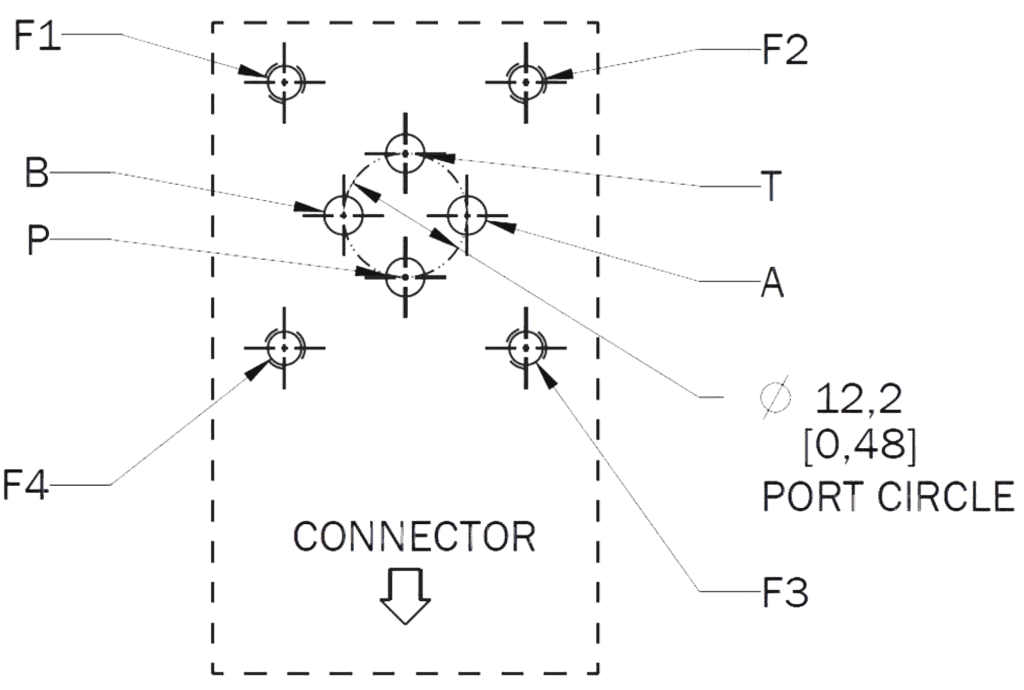

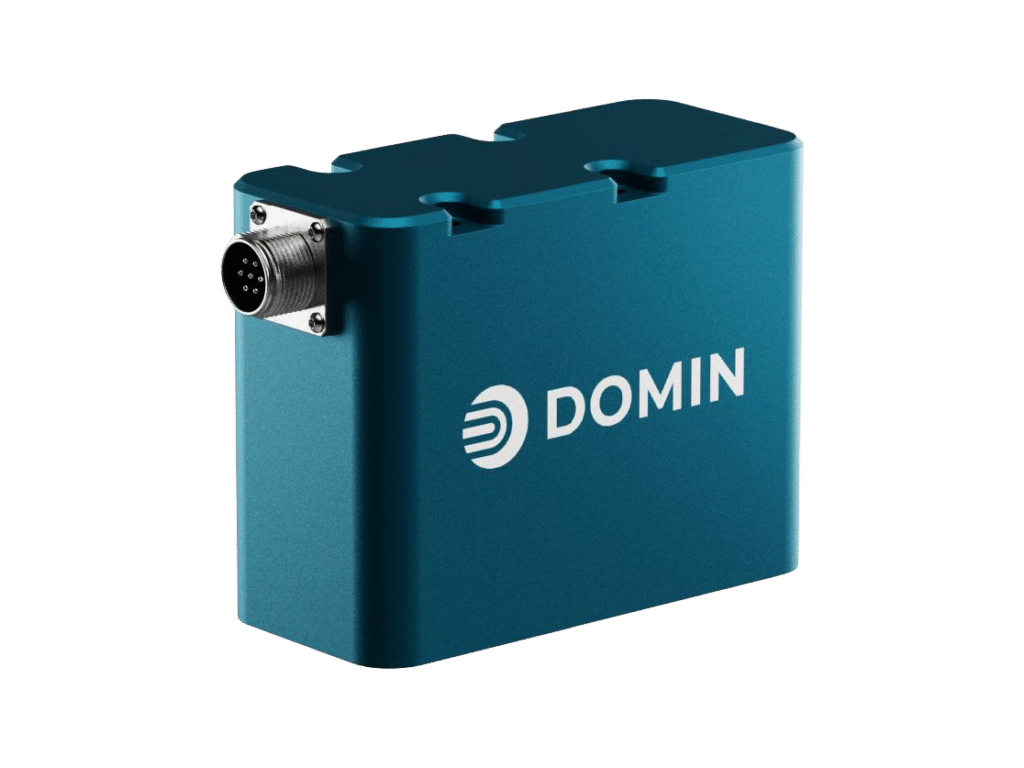

As the smallest direct drive valve in the world, the S4 Pro is a true game-changer. With its miniature port circle of 0.48 in (12.2 mm) and weight of less than 0.65lbs (300g), it’s perfectly suited for applications where space is limited but performance is paramount.

From demanding industrial settings to cutting-edge robotics and motorsport applications, the S4 Pro excels. Delivering superior performance, dynamics, and reliability in an ultra-compact package, it introduces a new era of control and productivity with the Domin S4 Pro series.

Available on S01 port pattern as standard.

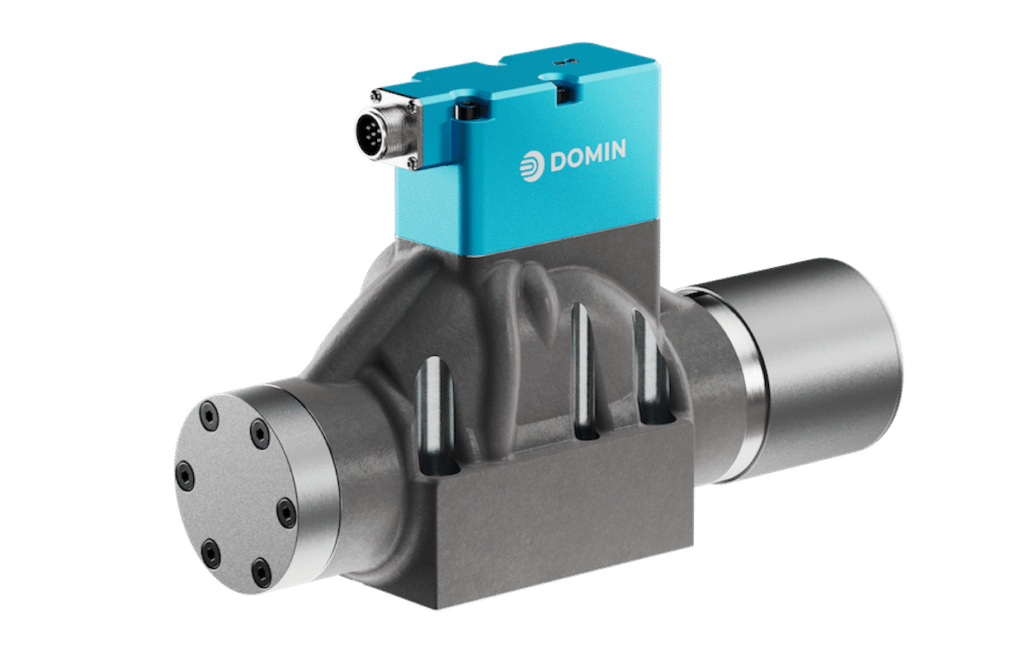

Popular Upgrade Models:

Key Specs:

Key Features:

Standard Modification Options:

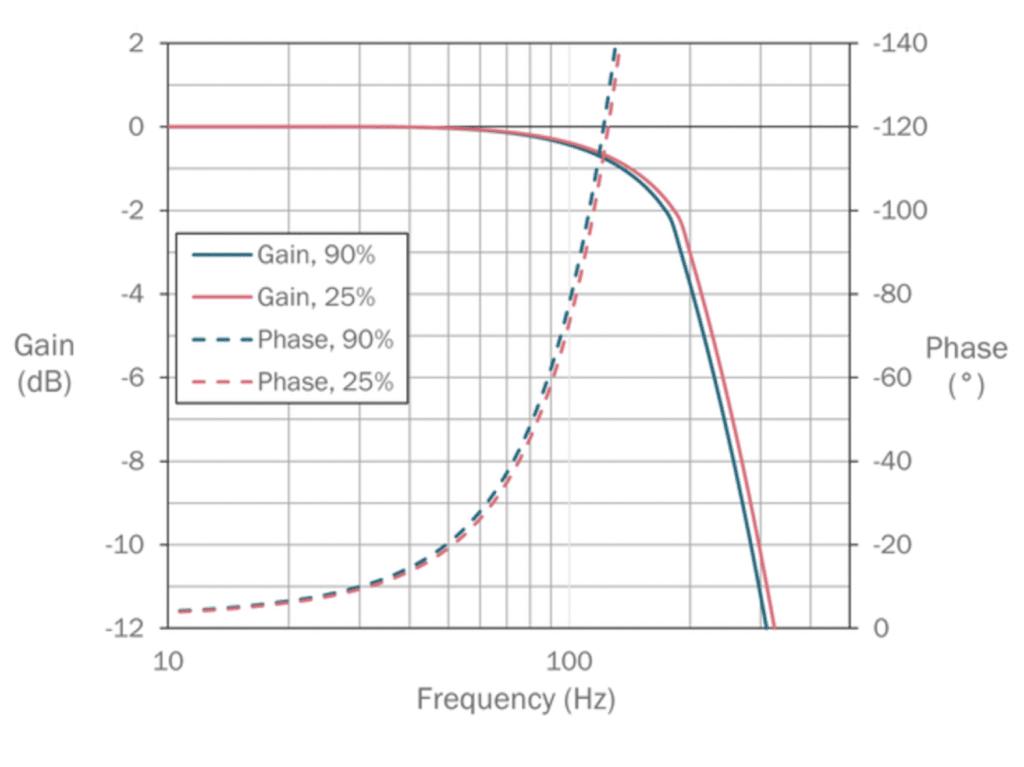

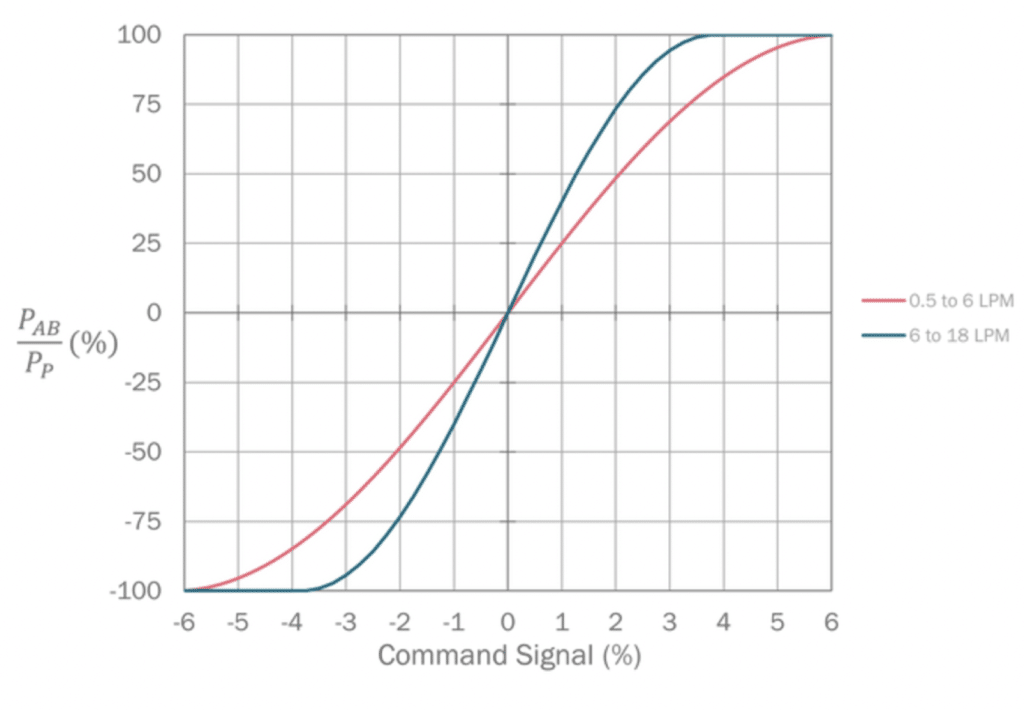

Technical Data

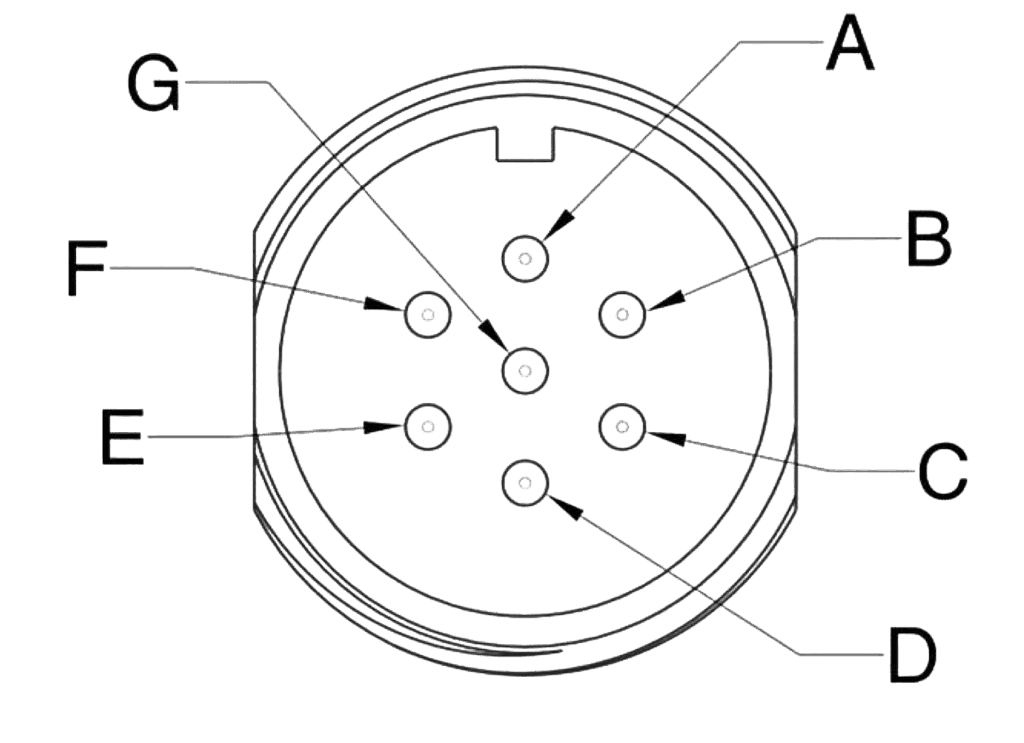

Ordering Code

S4 Pro 1 2 3 4 5 6 7 8 9

Variants on Request

Domin is proud of their ability to offer tailored solutions that meet customers’ specific needs. If you require a non-standard configuration, or a bespoke modification, we are confident we can provide you with the best solution. Talk to us here and one of our team will respond as soon as possible.

Domin is a supplier and servo valve manufacturer for various applications including automotive/motorsports, aerospace, animatronics, simulation, robotics, and marine.