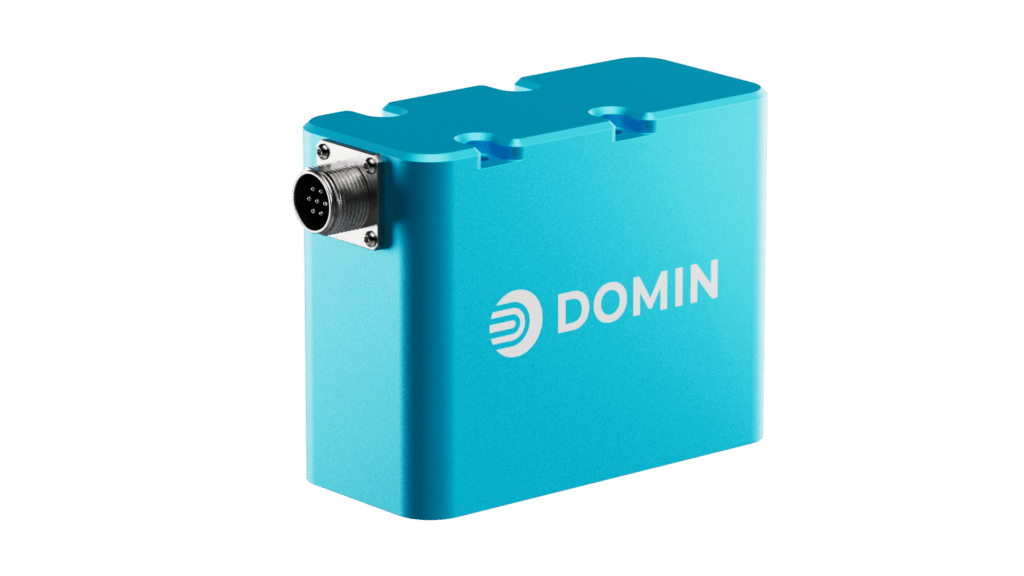

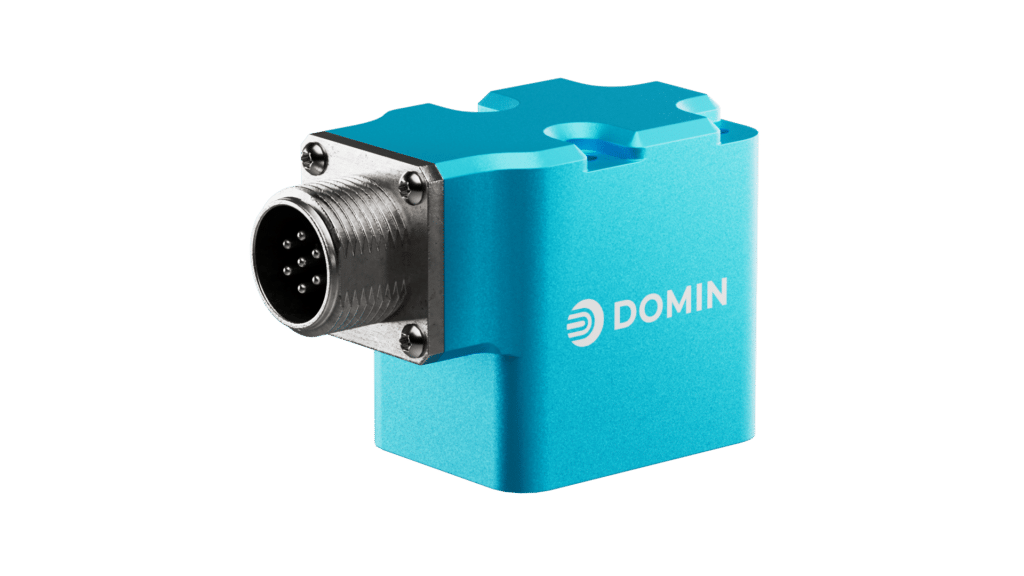

Hydraulic Servo Valves – S6 Pro

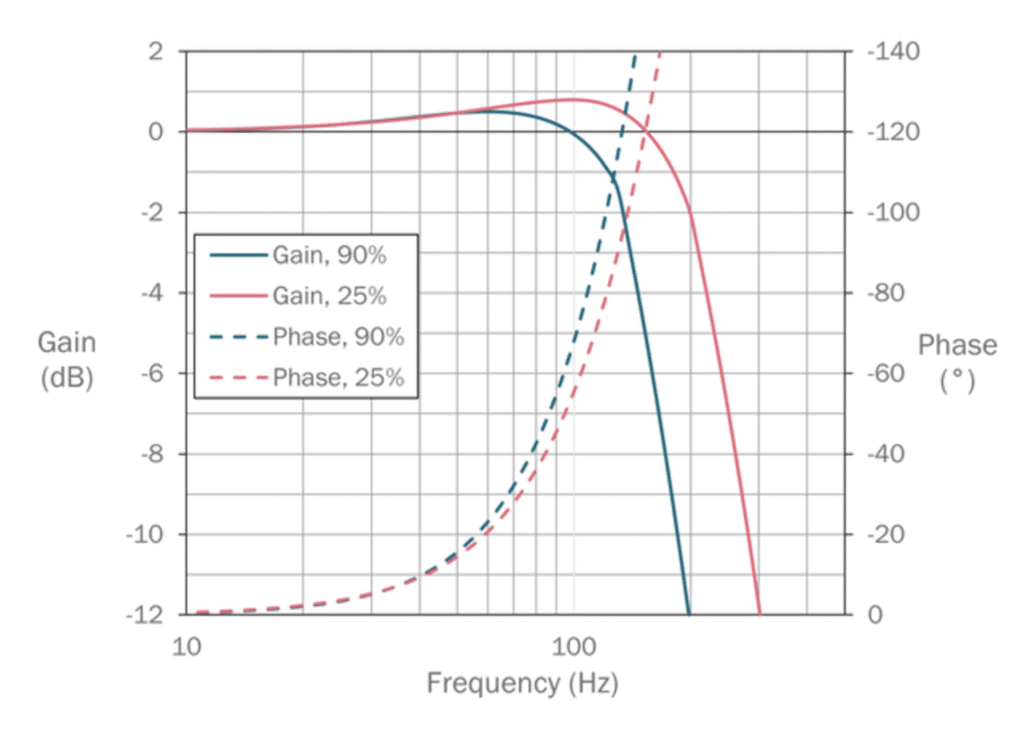

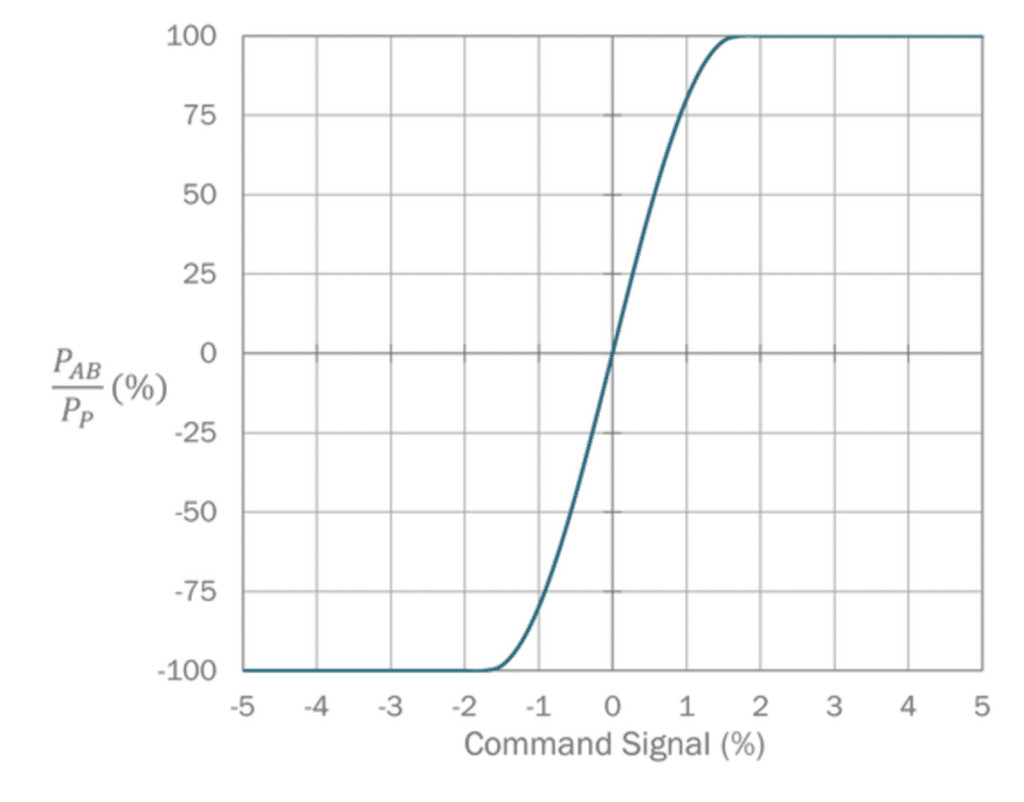

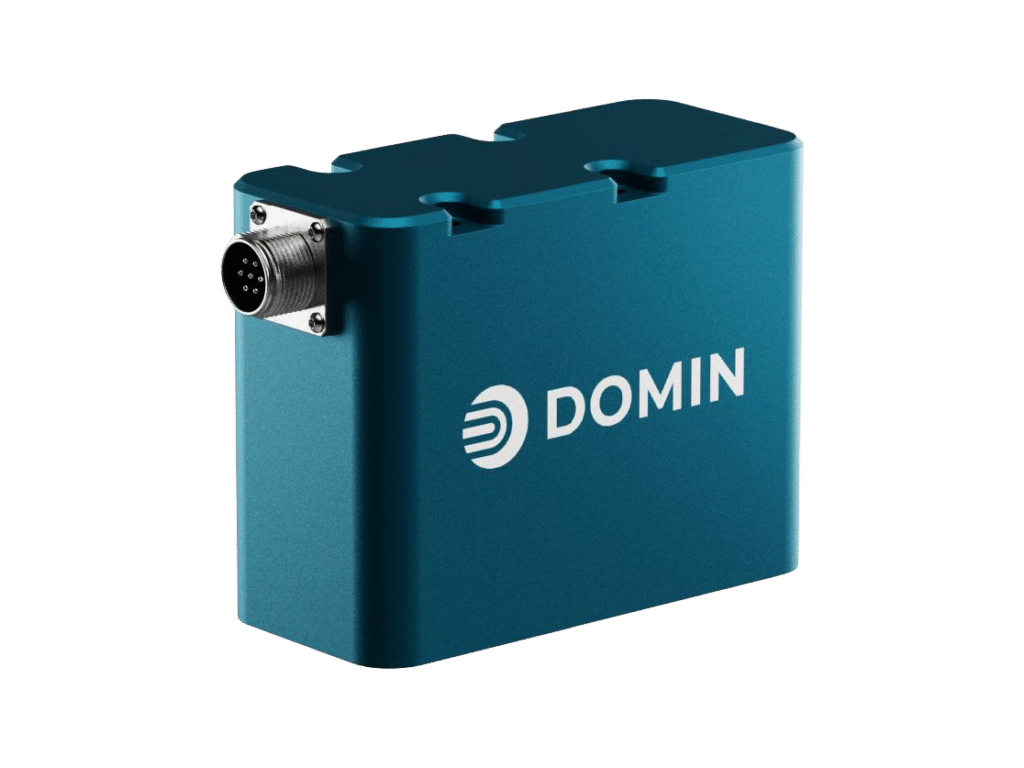

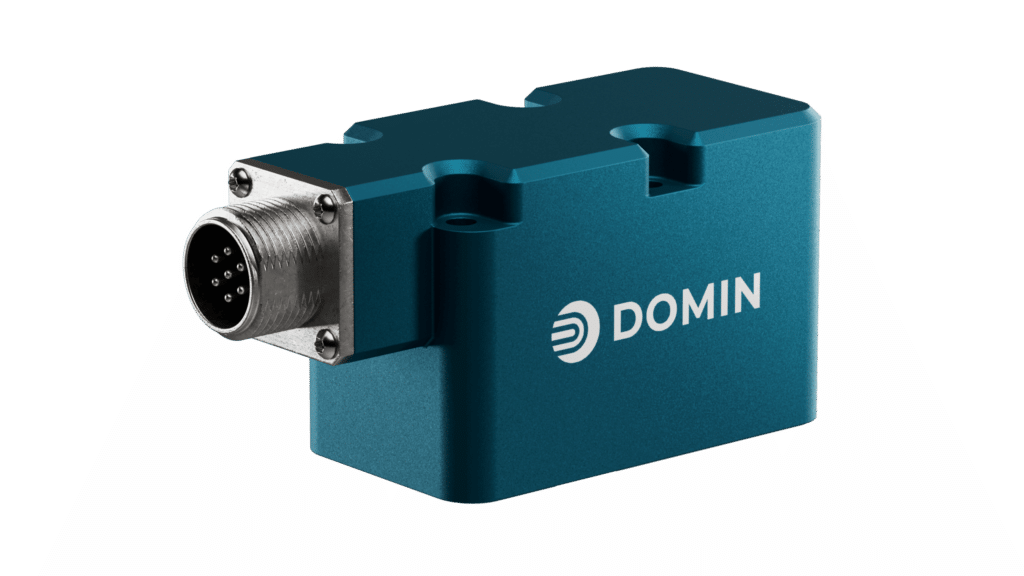

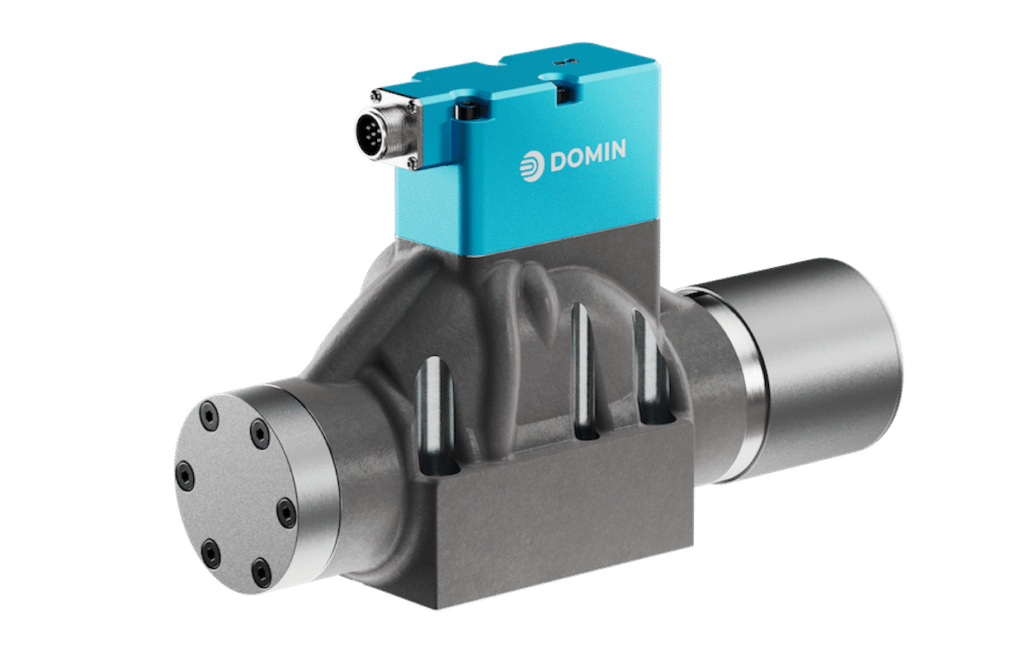

The Domin S6 Pro direct drive servo valve (DDV) has been designed to achieve the best characteristics from two competing valve technologies: fluid amplified EHSVs and DDVs. The S6 Pro has the size, mass, and dynamic capabilities of the most compact EHSV, and the low quiescent leakage and reliability of the best DDV.

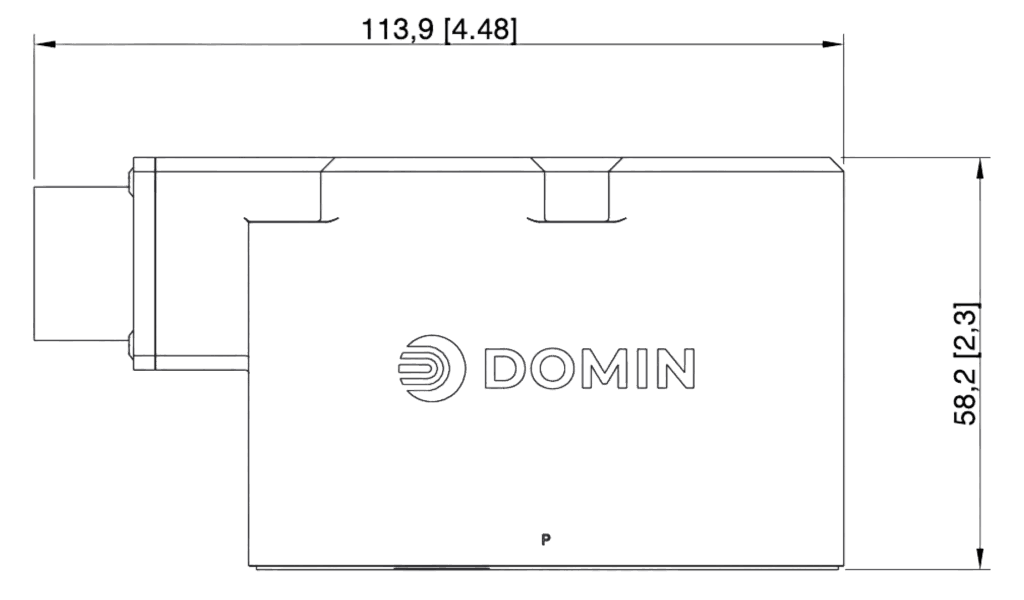

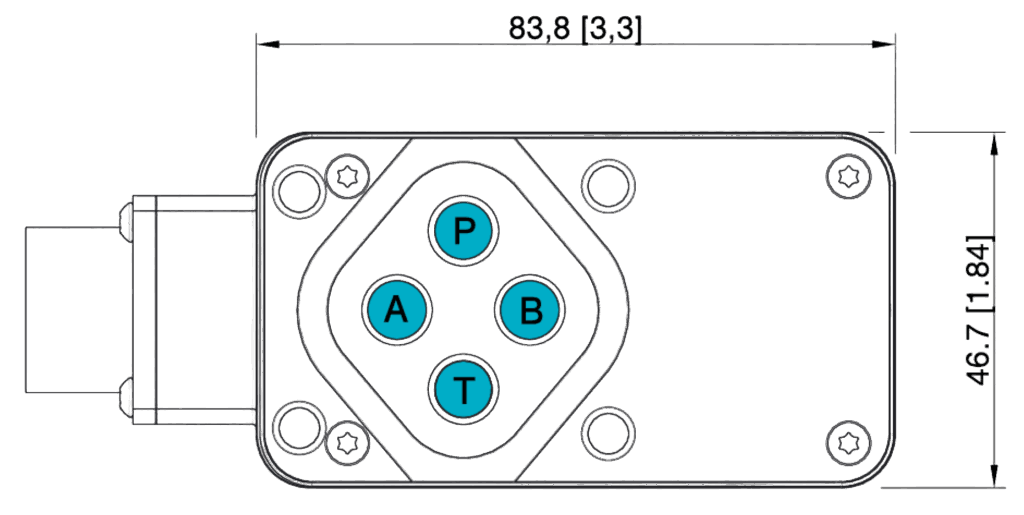

For applications requiring the results of the S6 Pro X, the S6 Pro model can be upgraded with a mounting plate adapter to achieve the same functionality.

Discover Ultimate Power Density

Experience optimal performance without compromise. Whether in test simulation or industrial manufacturing, the S6 Pro ensures seamless operations and maximum productivity, thanks to its superior design and exceptional power density.

With the Domin S6 Pro, you get the best of both worlds: the size, mass, dynamic capabilities, and industry-leading power density of the most advanced two-stage valves, paired with low quiescent leakage and unwavering reliability. Experience effortless efficiency, precision and power with the Domin S6 Pro series.

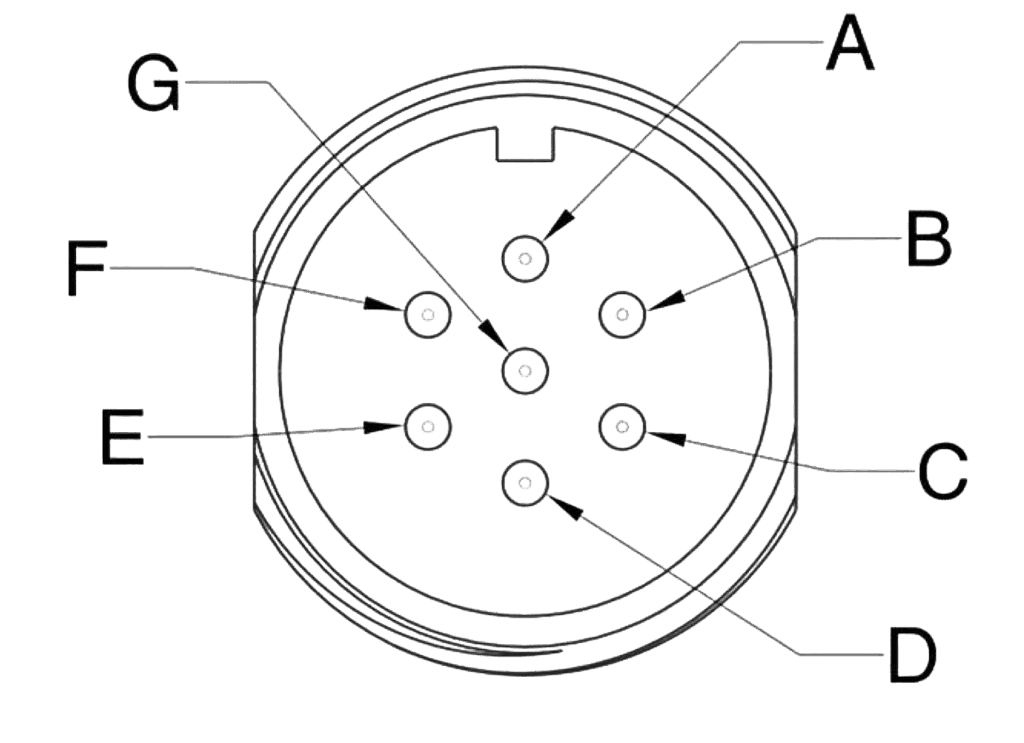

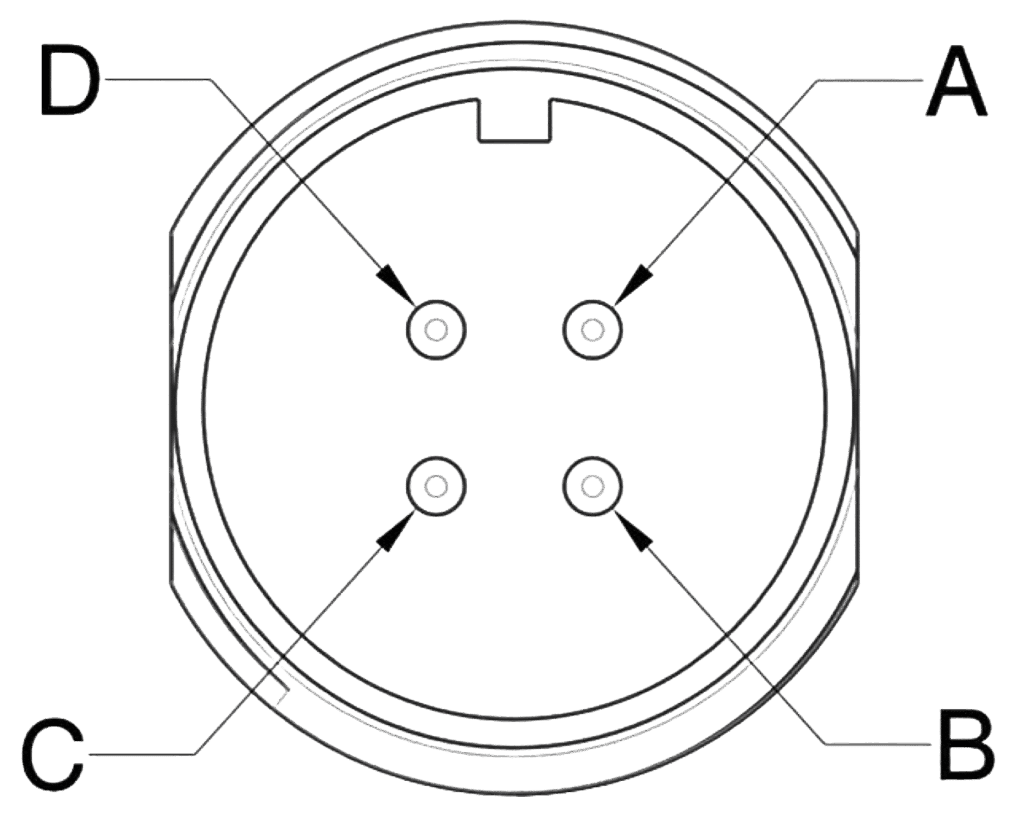

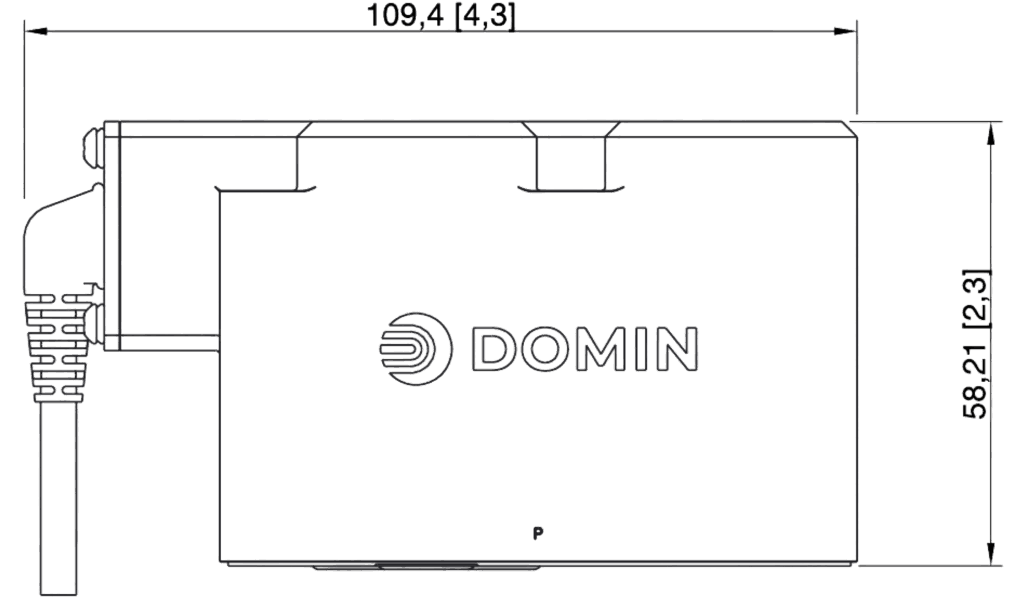

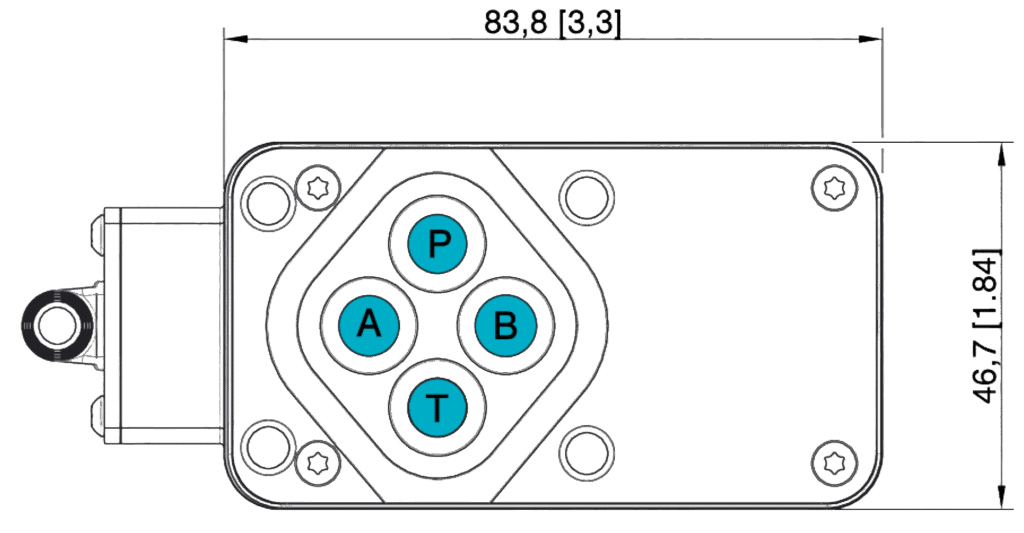

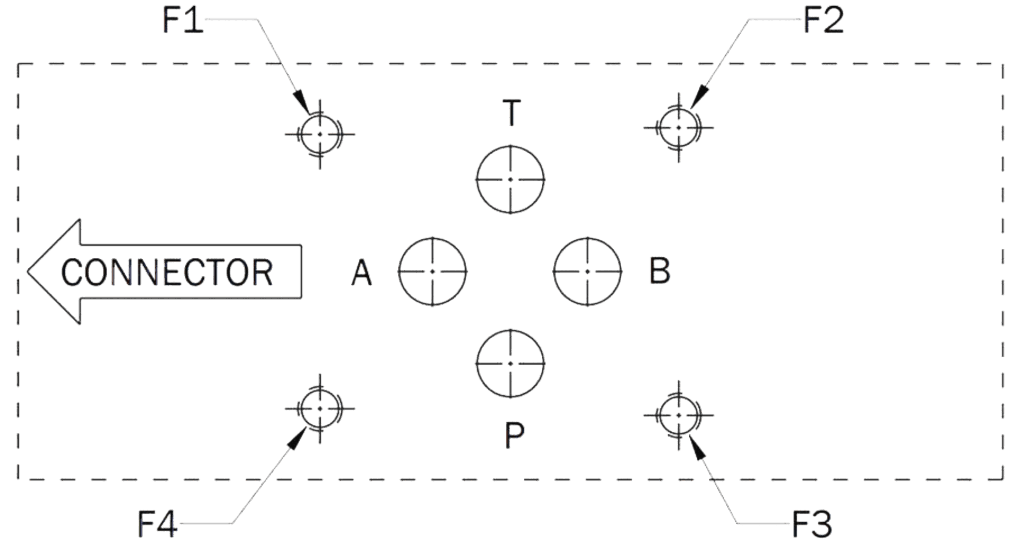

Available on NG06 port pattern as standard.

Popular Upgrade Models:

Key Stats:

Key Features:

Standard Modification Options:

Technical Data:

Ordering Code

S6 Pro 1 2 3 4 5 6 7 8 9

Variants on Request

Domin is proud of their ability to offer tailored solutions that meet customers’ specific needs. If you require a non-standard configuration, or a bespoke modification, we are confident we can provide you with the best solution. Talk to us here and one of our team will respond as soon as possible.

Domin is a supplier and servo valve manufacturer for various applications including die casting, injection molding, wood/timber machines, vibration equipment, metal processing, and simulation.