Hydraulic Test Cylinders

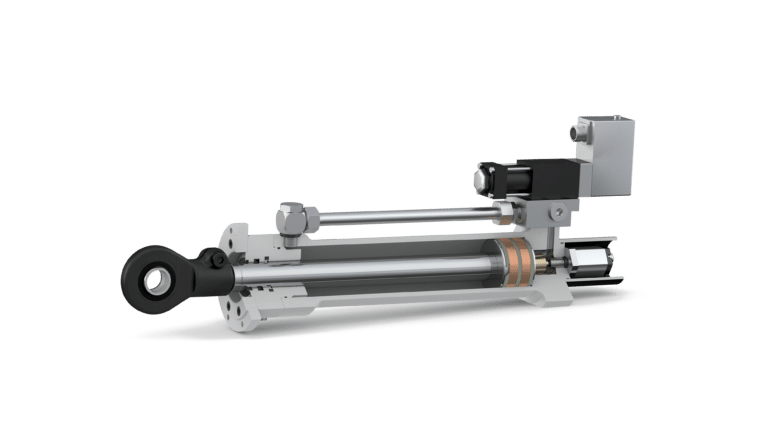

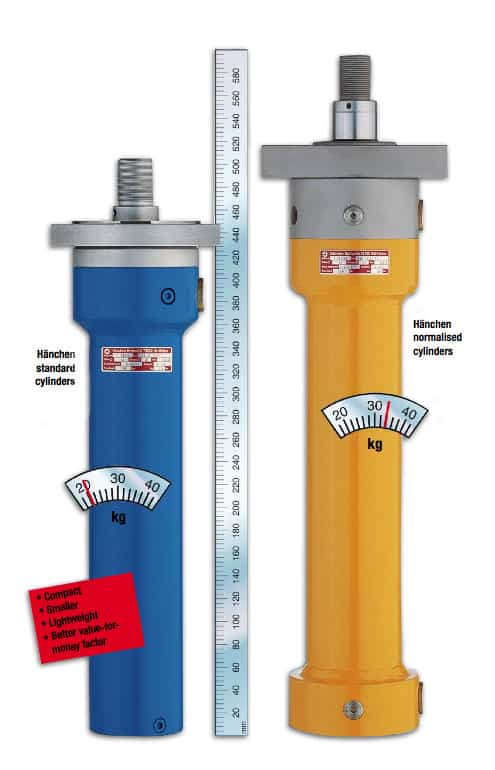

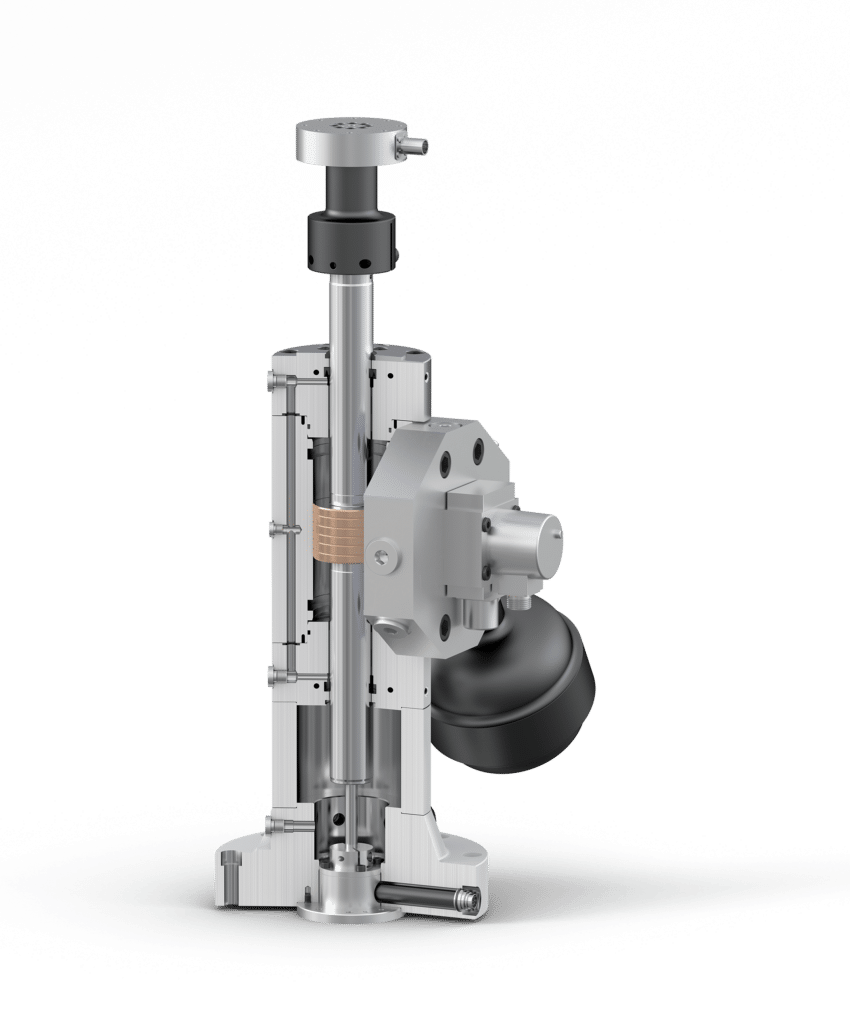

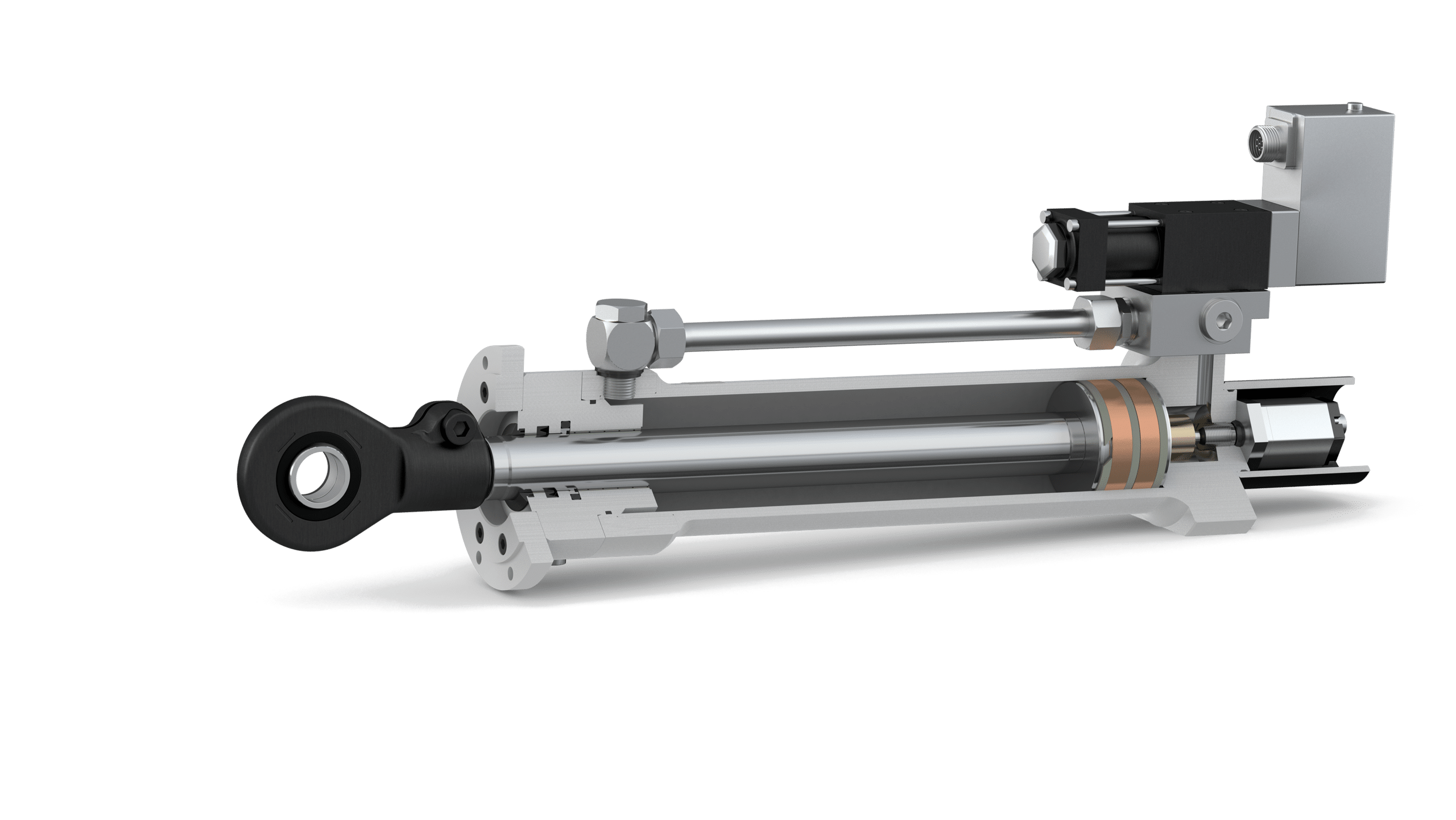

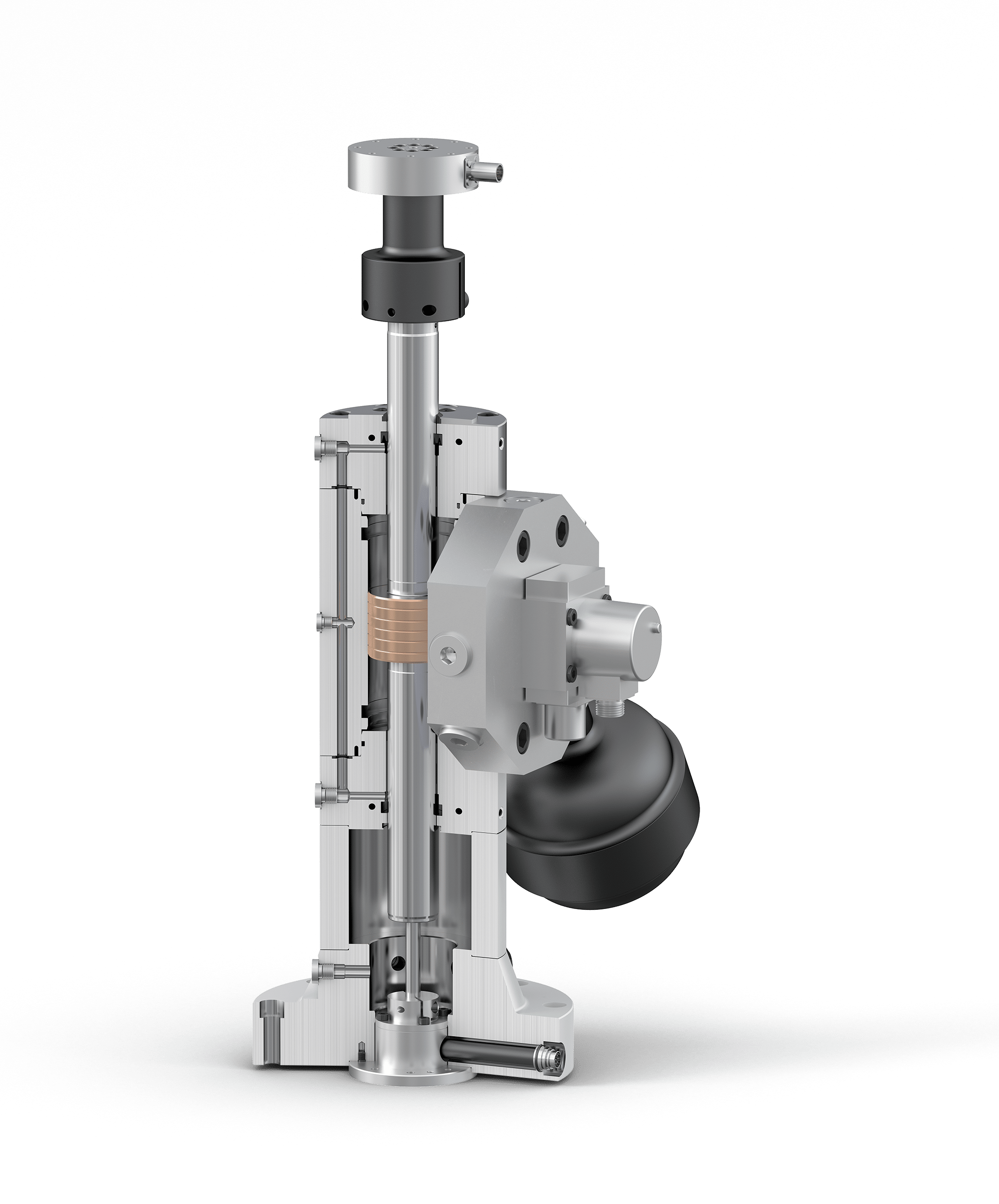

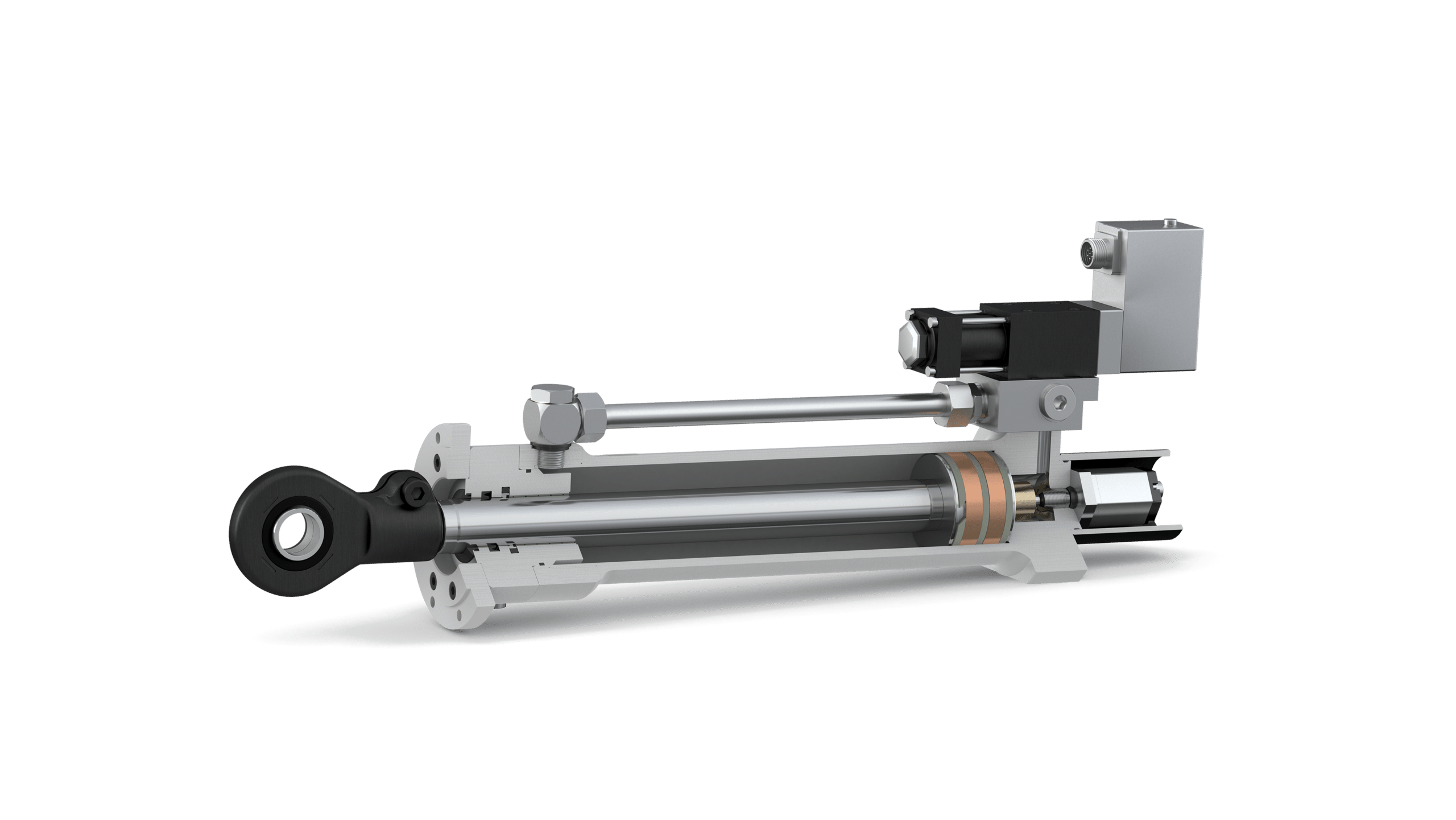

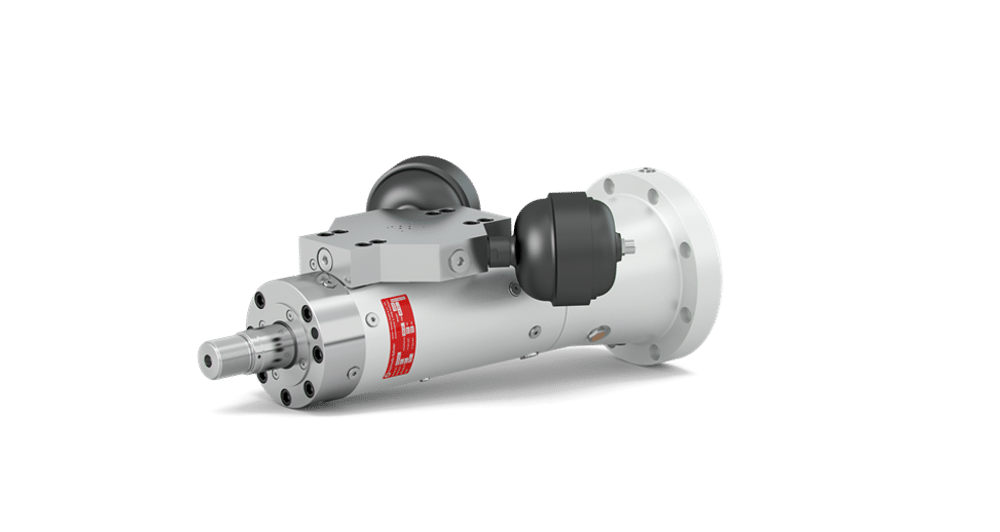

For over 100 years, Hänchen has supported the test and simulation industry with actuators built for precision and durability. Our servo cylinders cover one of the widest ranges on the market. Choose from lightweight models for simple tests (Series 120/300) to hydrostatic models for demanding, high-frequency applications (Series 320). With patented sealing technologies found nowhere else in the market and highly-honed surface finishes, Hänchen cylinders last for decades in service.

One of the largest testing ranges in the market, offering lightweight models for static applications or high frequency cylinders for dynamic testing.

Need Support? We Can Help.

What Makes Us Different?

Largest Testing Range on the Market

o Offering lightweight servo actuators for static applications and ultra-rigid cylinders for dynamic testing.

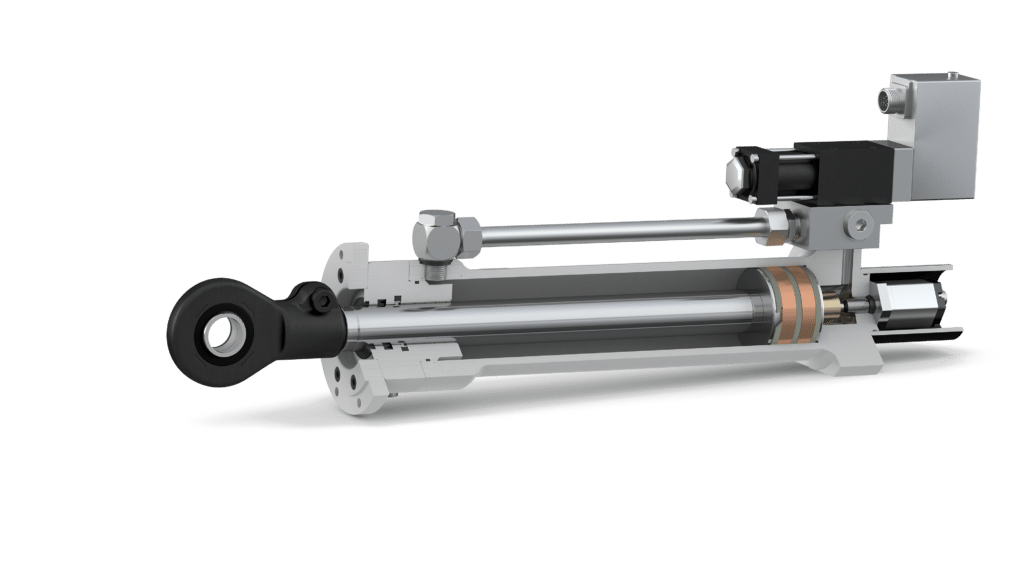

12 Sealing Combos for Low Friction and Stick-Slip

Customize your cylinder for static or dynamic loads with patented sealing technology to minimize friction, stiction, and side loads.

Fast Lead Times with Competitive Pricing

Competitive pricing and fast manufacturing (as quick as 14-18 weeks) compared to popular brands, like MTS.

Test Cylinders 101

What are Test Cylinders?

Test cylinders are used extensively in the testing sector and can be used for checking the functional safety of systems, component parts or products, for structural testing of airplanes, refrigeration compressors, automobile exhaust systems, or for simulating loads and movements, such as operational profiles and flight profiles.

Product Benefits

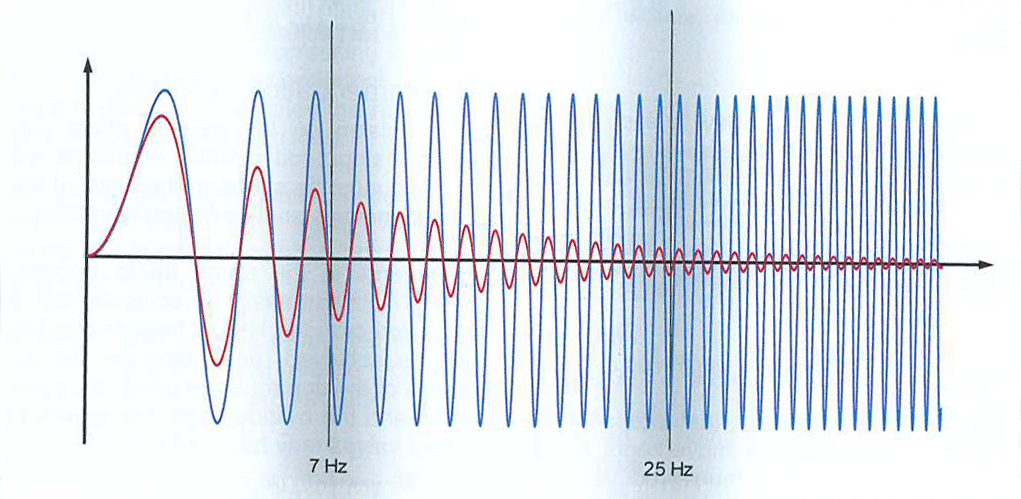

Stick-Slip in Hydraulic Cylinders

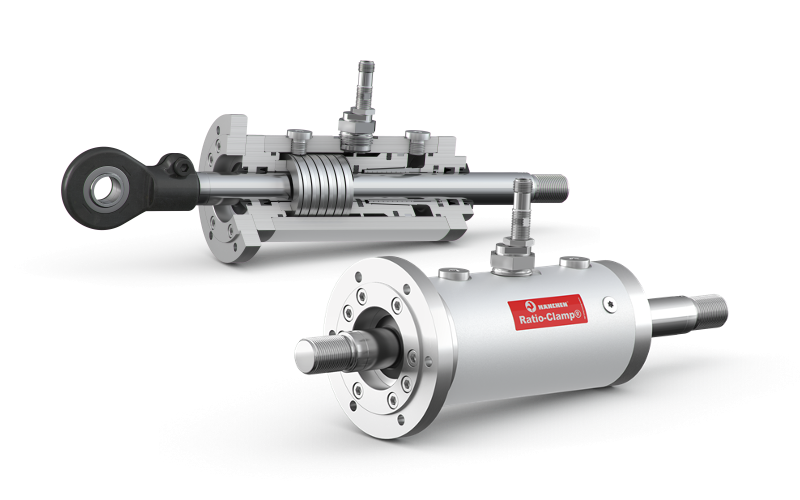

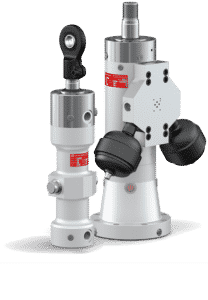

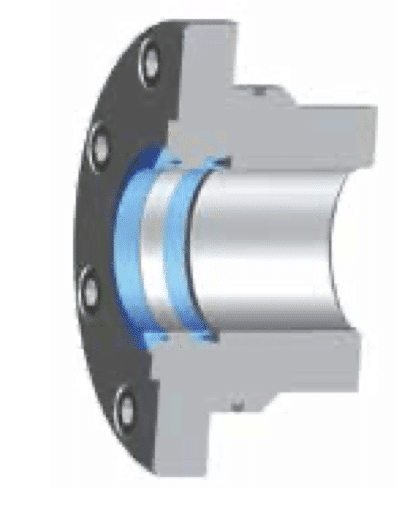

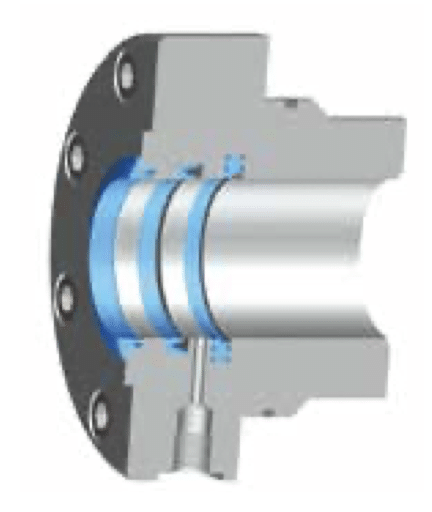

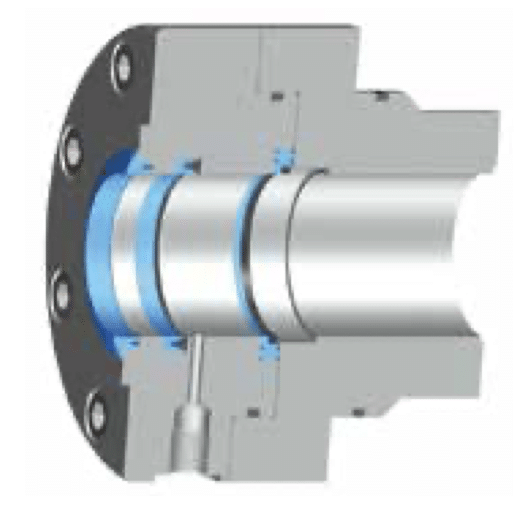

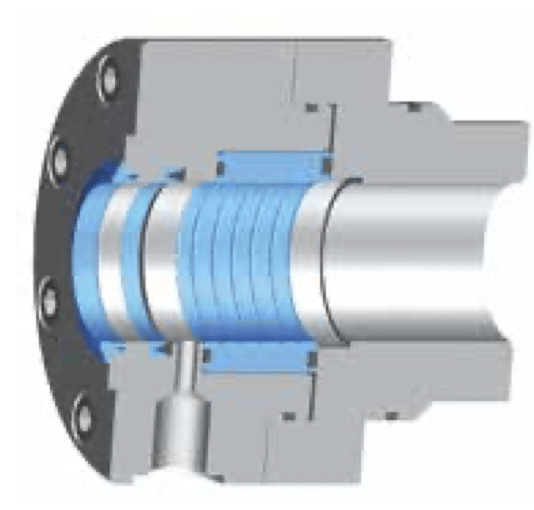

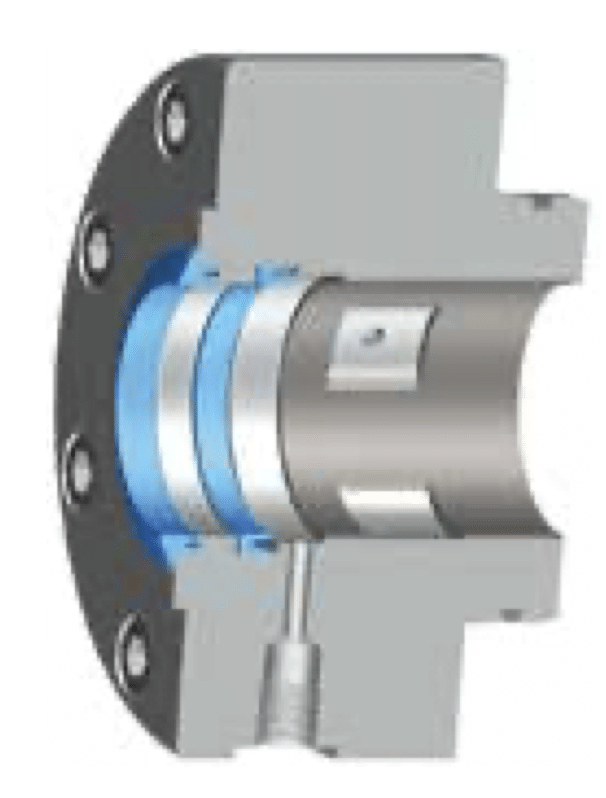

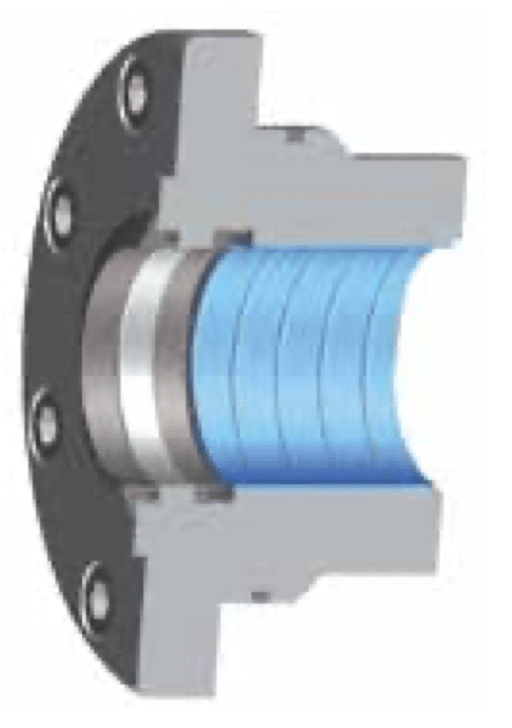

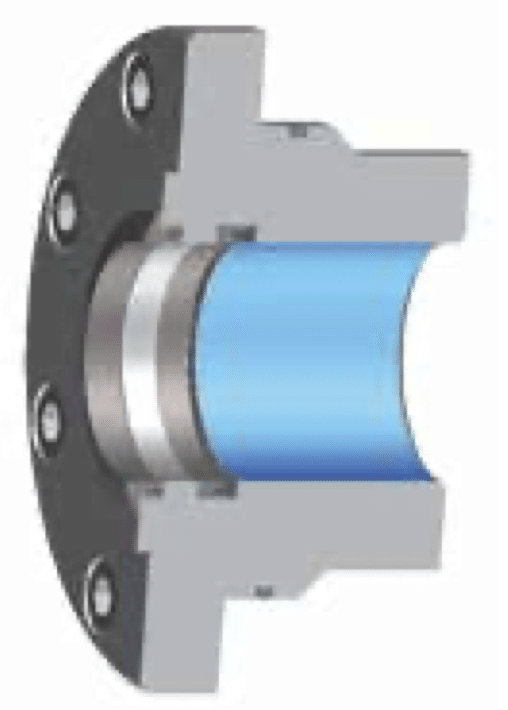

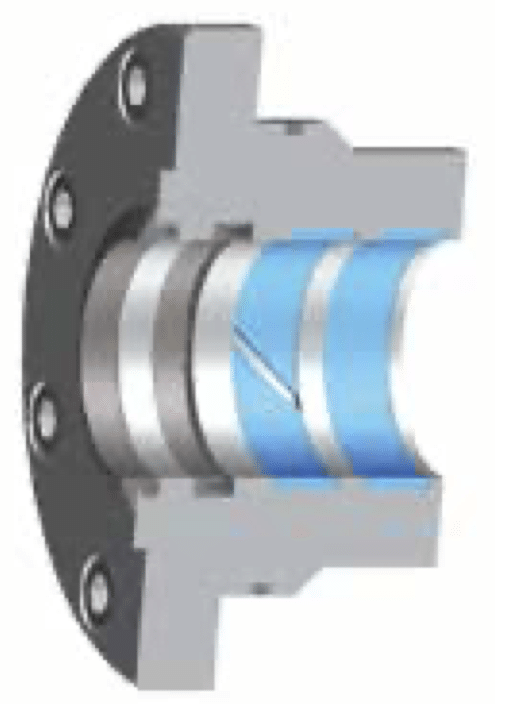

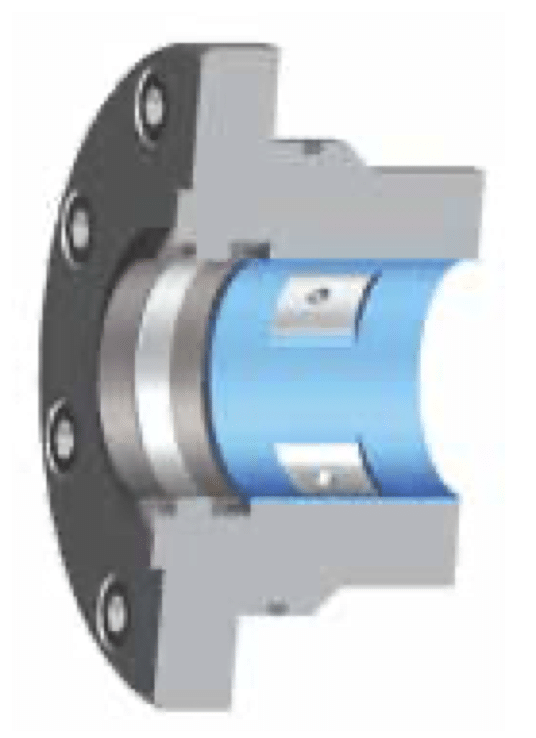

Our Hydrostatic Design

Hydraulic Test Cylinder Sealing Options

Tell us about your application, and we will help you find the perfect seal. Any solution is possible for your application. We make patented and standard seals for low friction, side loading, high pressures, rotation, fast/slow movement, stroke amplitude, and medium compatibility.

In the following chart, the first row of images and titles denote sealing systems, while the first column on the left denotes guiding systems.

|

Basic Design

|

Servocop®

|

Servoseal®

|

Servofloat®

|

Functional oil seal

| |

|

Servoslide®

|

– Simple movements |

– Controlled movements |

– Sensitive movements |

– Sensitive movements | |

|

Metallic guide

|

– Simple movements |

– Simple movements |

– Simple movements |

– Simple movements | |

|

PTFE Wear rings

|

– Controlled movements |

– Sensitive movements |

– Sensitive movements | ||

|

Servobear®

|

– Sensitive movements |

Application Examples and Solutions

Hydraulic Test Cylinders are used in a wide variety of applications including automotive testing such as lifecycle tests, aerospace system tests such as load and environmental condition simulation, and fluid power operating condition simulation.

Automotive

Servo hydraulic lifecycle tests are the current industry standard for automobile components that are used far beyond safety-related structural elements. Users can depend on hydraulic test actuators for high positioning accuracy and reliability in applications for test systems and real time control. A test cylinder with a dynamic lift of up to 35 mm (1.3 in.), speed of 1.3 m/s (51.2 in/s), and acceleration of up to 50 m/s (1968.5 in/s) could be used for a test load requiring up to 28 kN (6,294 lbf) and a frequency up to 20 Hz.

Aerospace

System tests that simulate loads and environmental conditions in different flight phases are particularly demanding. To test the landing flaps and slats, servo hydraulic cylinders could be used here to replicate the airflow that involves rapidly changing forces with irregular parameters. For example, a servo cylinder with a bore between 40 to 160 mm (1.5 to 6.2 in.) could be used for a test stand with a holding force between 140 – 300 kN (31.4 to 67.4 lbf) and a stroke requirement of 300 to 1,670 mm (11.8 to 65.7 in.).

Fluid Power

To determine the characteristic values of a seal, seal test benches are suitable for simulating a wide range of operating conditions. Double rod cylinders could be used here for fatigue tests focused on examining the frictional force of the seals, tightness on rods and shafts.