Hydraulic Cylinders

With our trusted network of cylinder partners, we can make any cylinder possible. Our flagship brand, Hänchen, has been producing durable testing actuators for over 100 years. Our range extends further from standard and commodity-grade cylinders to large-scale industrial actuators and everything in between.

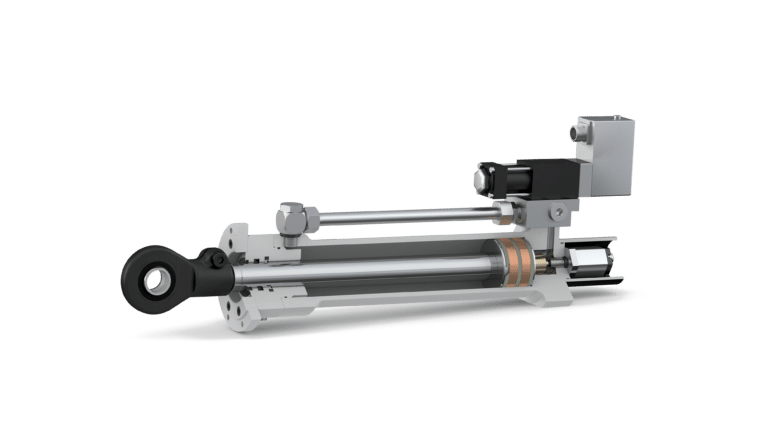

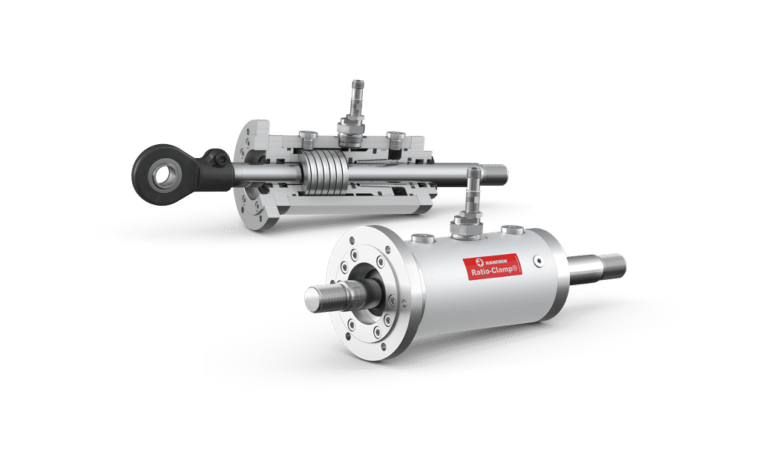

One of the largest testing ranges in the market, offering lightweight models for static applications or high frequency cylinders for dynamic testing.

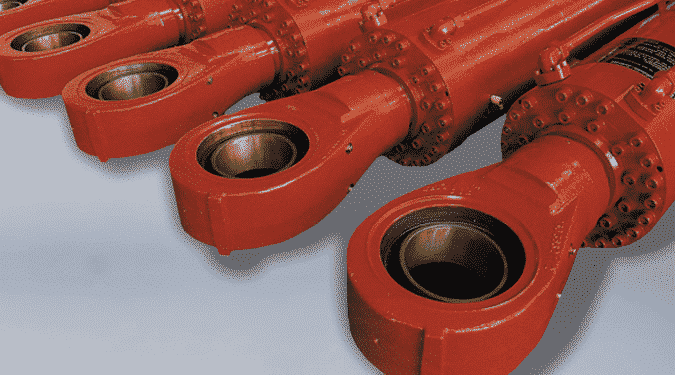

Standard Hydraulic Cylinders with a wide variety of standard dimensions, connections, and mounting options.

Rod Locking Devices are a safety holding device that prevents movement until released by hydraulic pressure.

Custom Cylinders can be specifically tailored to almost any requirements you can imagine.

Up to 70% lighter than traditional steel cylinders, offering weight advantages, cost-savings, and energy efficiency in many different industries.

Need Support? We Can Help.

What Makes Us Different?

Any Size Cylinder is Possible

From cylinders the size of a soda can to cylinders weighing over 280 tons

Large OEM Quantities or Custom Designs

Well-suited for all applications from simple construction or AG cylinders in OEM quantities to one off custom design

Responsive Vendors on Speed Dial

Quick, direct line to the people making your parts (some, of course, move faster than others)

Product Benefits

Applications

Carbon Hybrid Cylinders Used in Glass Transportation

In transportation, the increasing weight of glass panes and glass assemblies places greater demands on vehicle weight limits and space efficiency. As a solution, carbon hybrid cylinders have been adopted as a lighter alternative to traditional steel cylinders.

In glass loaders, these cylinders serve two main functions. They help lift and lower the glass panes into the trailer and then hold them firmly in place during transport to prevent vibration and breakage. Since the composite housing is made of a carbon fiber and aluminum hybrid, the cylinder weight is reduced from about 26.5 lbs (12 kg) to 12 lbs (5.5 kg). This means greater payload capacity for the vehicle and lower CO₂ emissions during transit.