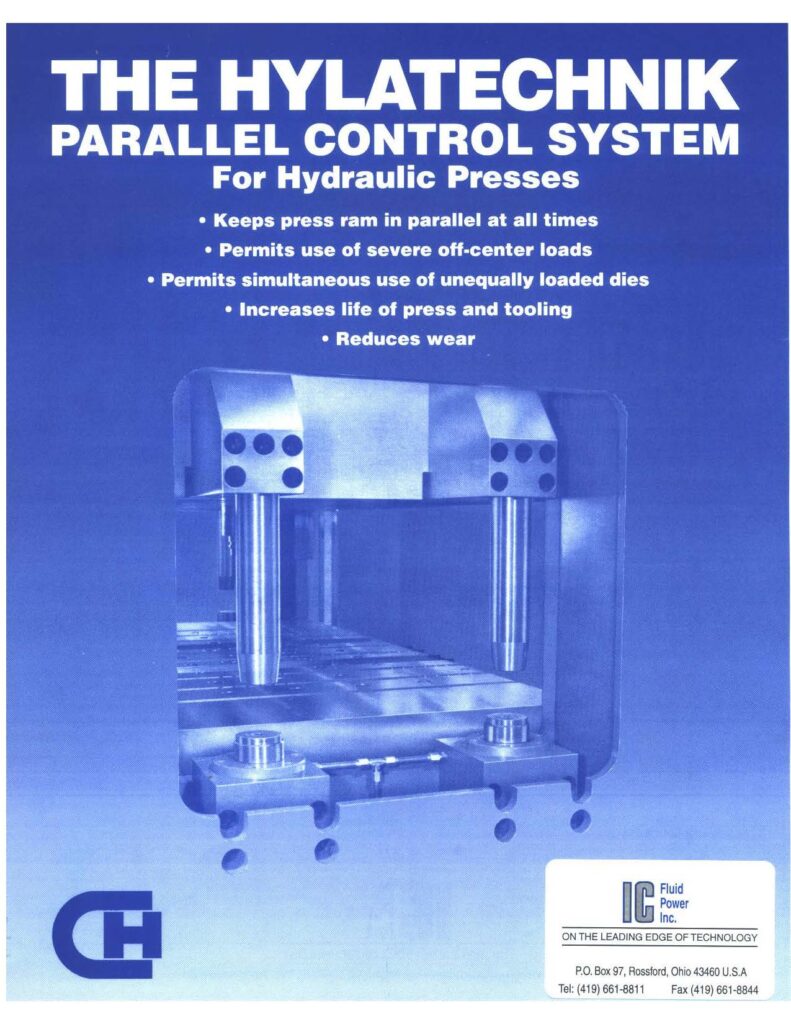

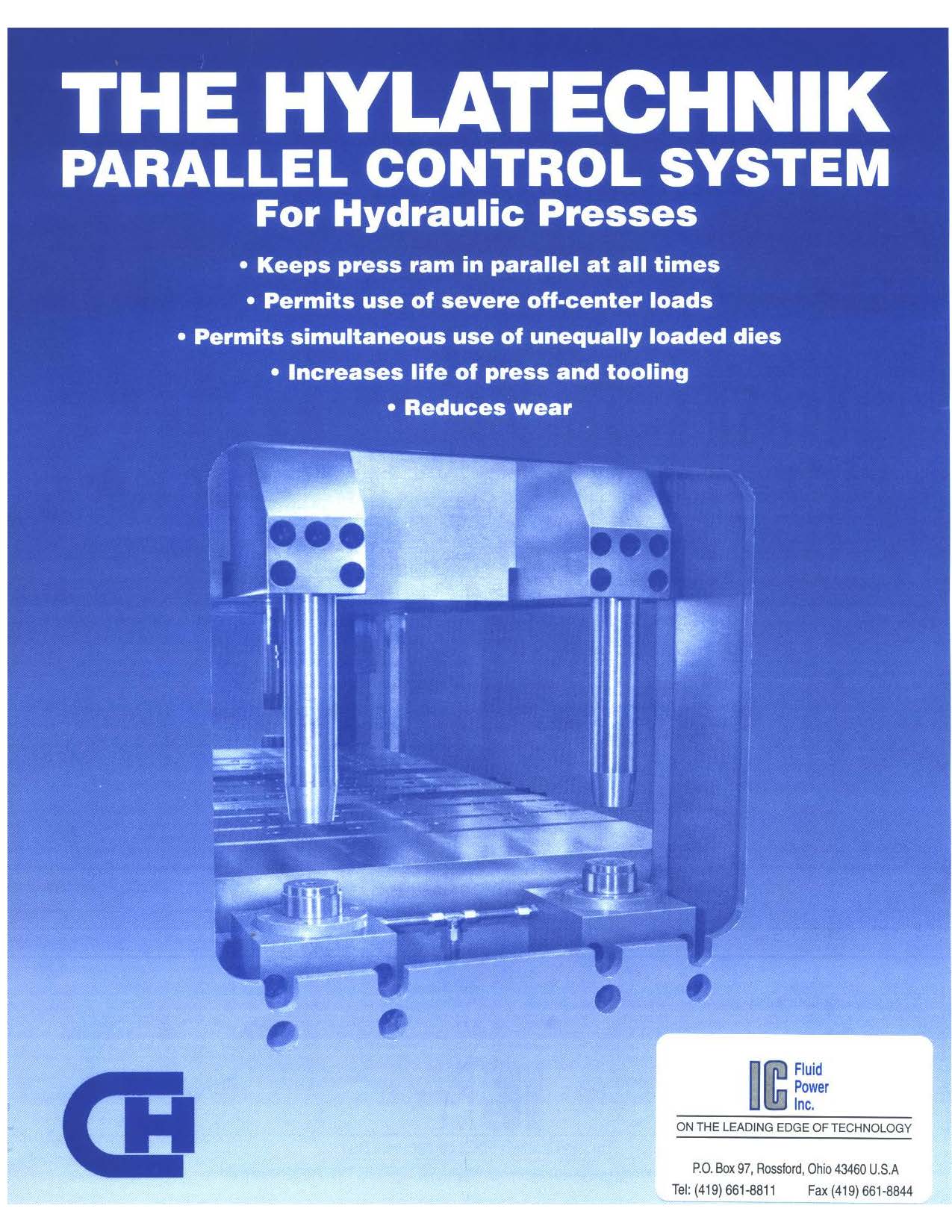

HYDRAULIC PRESS PRODUCTS — PARALLELISM CONTROL SYSTEM

Hydraulic Press Products — Parallelism Control System

The Hylatechnik parallel leveling device preserves the life of presses and machine tools, increasing the economic return on your equipment and the quality of the work piece.

Often press manufacturers and tool makers are asked to design a press or die with severe off-center loads. The off-center load forces the slide to tilt placing high side thrust loads on the slide, gibs and frame. The result is abnormal wear of gib and slide liners, improper die alignment, reduced die life and lower part quality.

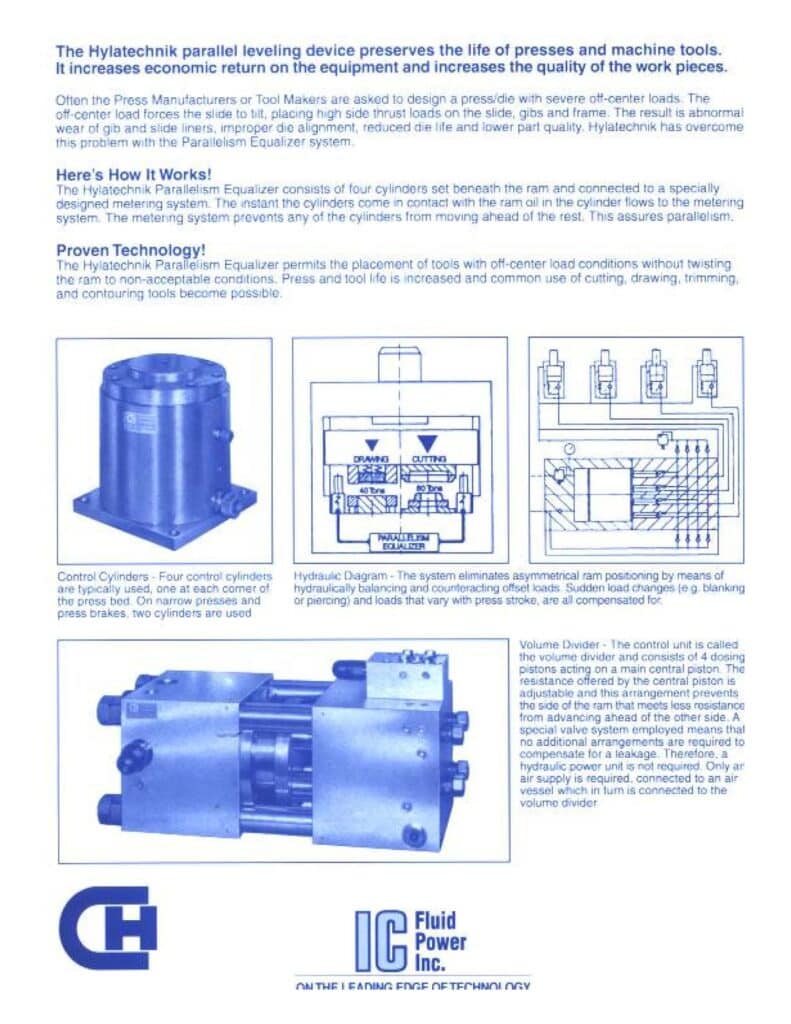

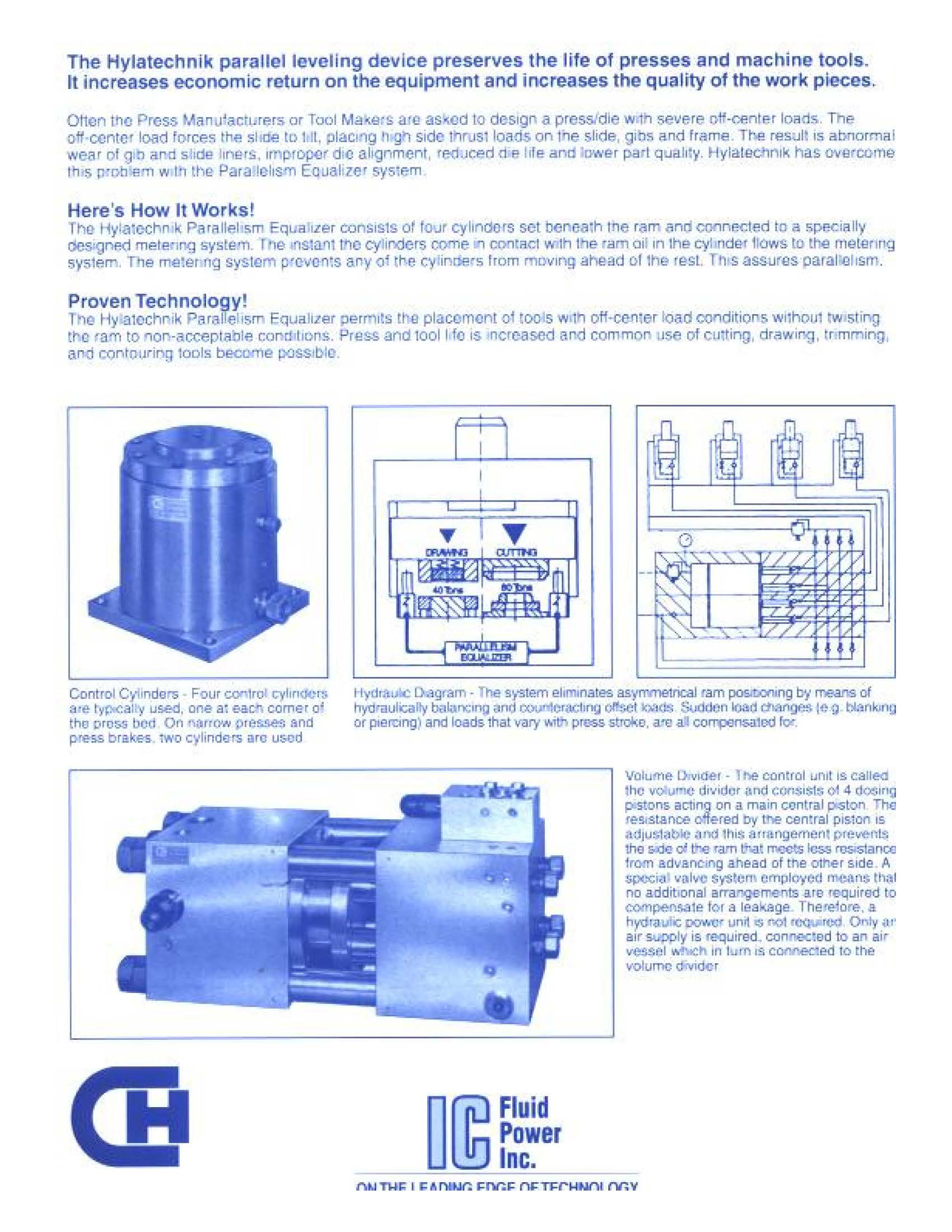

The Hylatechnik Parallelism Equalizer consists of four cylinders set beneath the ram and connected to a specially designed metering system. The instant the cylinders come in contact with the ram, oil in the cylinder flows to the metering system. The metering system prevents any of the cylinders from moving ahead of the rest, assuring parallelism.

The Hylatechnik Parallelism Equalizer permits the placement of tools with off-center load conditions without twisting the ram to non-acceptable conditions. Press and tool life is increased and common use of cutting, drawing, trimming and contouring tools become possible.

Purpose:

Results:

Hylatechnik is a supplier and hydraulic press product manufacturer for various applications including construction, mechanical, technological, and industrial.