HYDRAULIC PRESS PRODUCTS — SHOCK DAMPERS

Hydraulic Press Products — Shock Dampers

Have you ever been in a metal stamping facility and heard something that sounds like a train running into the building every time the press cycled? If you have, what you are hearing is an event called reverse tonnage and it is tearing up the press. In this short explanation, we will attempt to explain Reverse Tonnage also known as Snap-Through in a metal stamping press. Reverse tonnage is the undesirable results of cutting, blanking, and perforating operations. In the stamping process, the moment the punch meets the material, the press frame begins to deflect until the press has built up enough force to exceed the shear strength of the material and the punch breaks through. When this happens the press frame will release the stored-up energy and snap back past its original position or resting position into a compression load.

The press frame and components that are designed to function in a tension load are now in a compression load condition and all of this will occur in less than 20 milliseconds. At the instant of breakthrough during blanking, the press and dies are subjected to severe stress. This compression load condition on the press frame is called reverse tonnage and it can damage your press.

The conventional industry standard is to have presses designed to accept a reverse tonnage load that does not exceed 10% of the maximum forward capacity of the press. In other words, the maximum allowable reverse load for a 600-ton press is 60 tons. So, anything over 60 tons, you risk damaging your press.

So, what happens when we have too much reverse tonnage?

There are several ways to reduce reverse tonnage in a blanking operation:

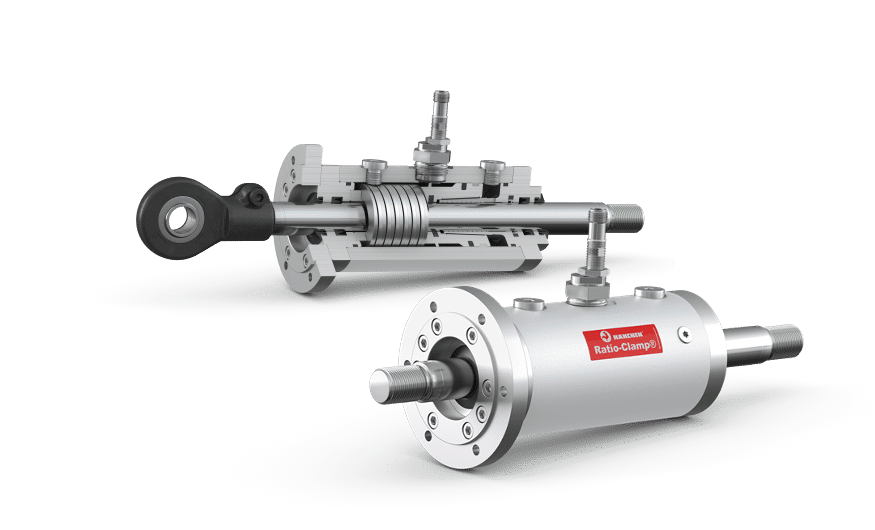

Many times, these reduction methods are not practical or may only minimally reduce the reverse tonnage on these heavy-hitting jobs. However, the hydraulic Shock Damper is the solution. Hylatechnik developed the hydraulic Shock Damper over 45 years ago and stampers from around the world have been protecting their equipment by using them.

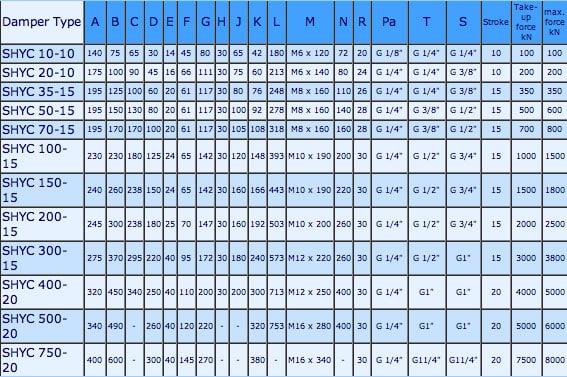

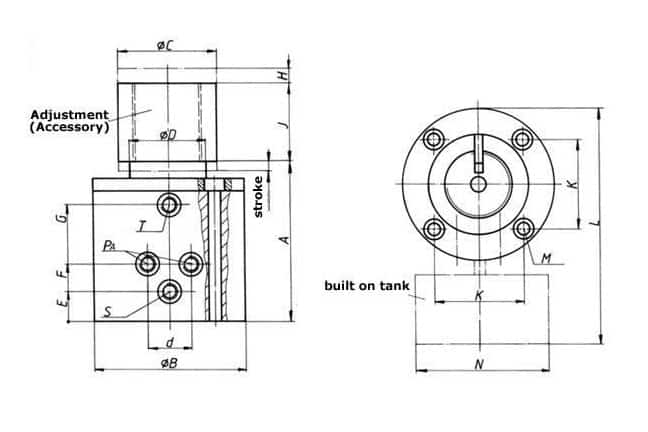

Hylatechnik Shock Dampers are designed to protect the press and tooling from snap-through loads. The Hylatechnik dampers will reduce or eliminate reverse loads, floor vibration, noise, and will increase tool life as well as forward tonnage in many applications.

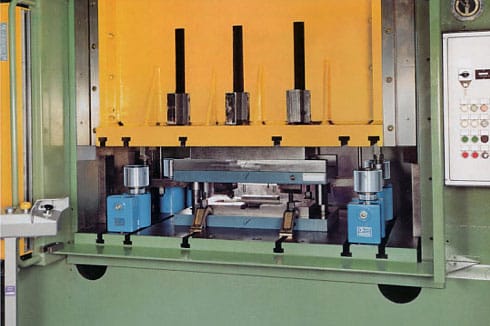

Applications include hydraulic presses, mechanical presses, and press breaks. The shock dampers are not limited to the press size. They can be used on the largest of machines.

Additional benefits of the Hylatechnik Shock Damper are:

Real-Life Customer Testimonials:

Reese Products: 25% Reverse load tonnage reduced to 0.01% on a 400-ton press:

As part of the demonstration, Press Automation installed Hylatechnik Shock Dampers onto a 400-ton Niagara press. Before the Dampers were added, the press was seeing a reverse load of 100 tons or 25% tonnage, significantly exceeding the recommended 10% of the rated forward load in a reverse load situation. By placing the Hylatechnik Dampers on the press, the reverse load was reduced to 0.01% tonnage or 1.2 tons. There was also a substantial reduction in the noise around the press with the Dampers in place. FYI: 100 tons ÷ 400 ton press = 25%

Bobcat: 1700-ton press shows a drastic difference in vibration with Shock Dampers:

Shock Dampers tested on Bobcat’s 1700-ton press resulted in “a drastic difference in vibration felt and ‘crack’ heard. With the dampers, the press stroked almost as smooth as if the die was stroked empty,” Dave Owens, Manufacturing Engineer in a test report for Bobcat.

SKD Automotive Group: Blanking Stroke Dampers reduce vibration levels by 40%:

A customer contacted us for assistance in reducing floor vibration and reverse loads on their 1600-ton Version Press. The press was being used for a heavy blanking application, which caused severe floor vibration and high reverse loads. The vibration was so intense that it caused a shock that traveled to neighbors across the street, prompting them to contact local authorities and shut down the stamping facility’s production at 11:00 P.M. We were called to do a demonstration of the Hylatechnik Shock Dampers, along with an engineering firm, to document the foundation vibration caused by each press stroke. The results were remarkable and using the Hylatechnik Shock Damper System reduced the floor vibration by 40%. The Shock Dampers also reduced the reverse load within the press manufacturer’s acceptable range. In the assessment provided from HGC Engineering, Brian Howe, MEng, MBA, PEng wrote that the Shock Dampers “provided an improvement in vibration levels occurring on the press frame and transmitted to the surrounding ground.”

According to AIDA Americas research, they found that the reverse load can be reduced by 83%-99% in some of their presses by using the Hylatechnik Shock Damper.

To see the positive effects of the Hylatechnik Shock Damper on your press call the pros at IC-Fluid Power to arrange a demonstration. We can be reached at (419) 661-8811 or us@icfluid.com.

Hylatechnik is a supplier and hydraulic press product manufacturer for various applications including construction, mechanical, technological, and industrial.