HYDRAULIC PRESSURE INTENSIFIERS – HOW TO SELECT

Hydraulic Pressure Intensifiers – How to Select

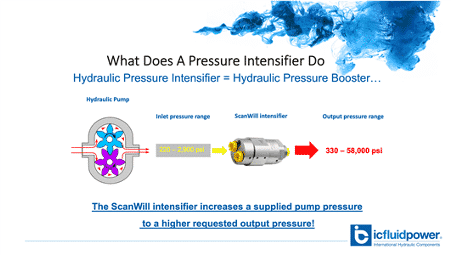

Since, we have decided we want to use a pressure intensifier to get that needed pressure to finish the job in a hydraulic application. Now, we need to select the right intensifier to install in your systems. But first, do we know what intensifiers do?

What does a pressure intensifier do? In short, the pressure intensifier does exactly what the name says—it boosts hydraulic pressure. This can be done in new systems or used in existing systems to increase the available pressure. In new systems, you can design the HPU for low / standard pressures and add the intensifier to handle the high-pressure situations. In refit applications, the intensifier can be installed inline, near where the increased pressure is needed without expensive replacement of the power pack. Hydraulic pressure intensifiers generate a higher pressure from a low-pressure hydraulic power source. They always work powered by a pump, which is operating at a set pressure and from this the intensifier generates a higher output pressure.

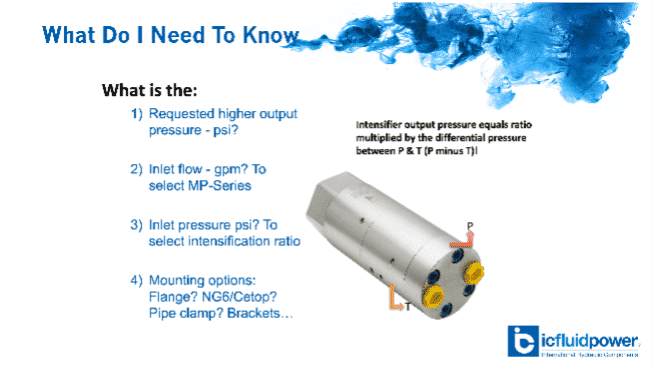

So, what information do I need to select the right intensifier? I need to know the required output pressure. What is the inlet flow and pressure and how are you going to mount it in the system?

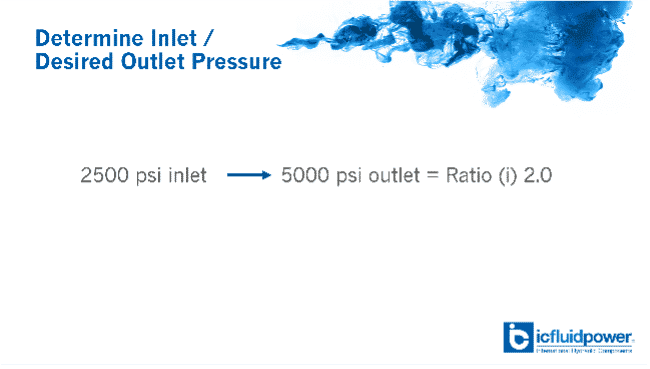

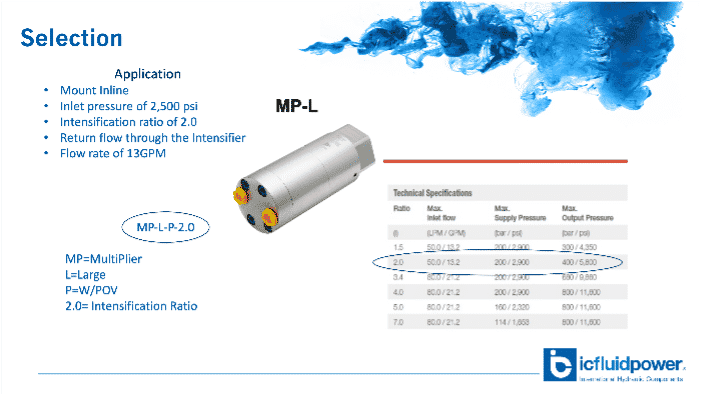

So, let’s determine the pressures ratios we need, For this example, we have a 2,500 psi system And need to boost it to 5,000 psi we will need an intensifier with a ratio of 2.0. We will also have an inlet flow of 13 GPM.

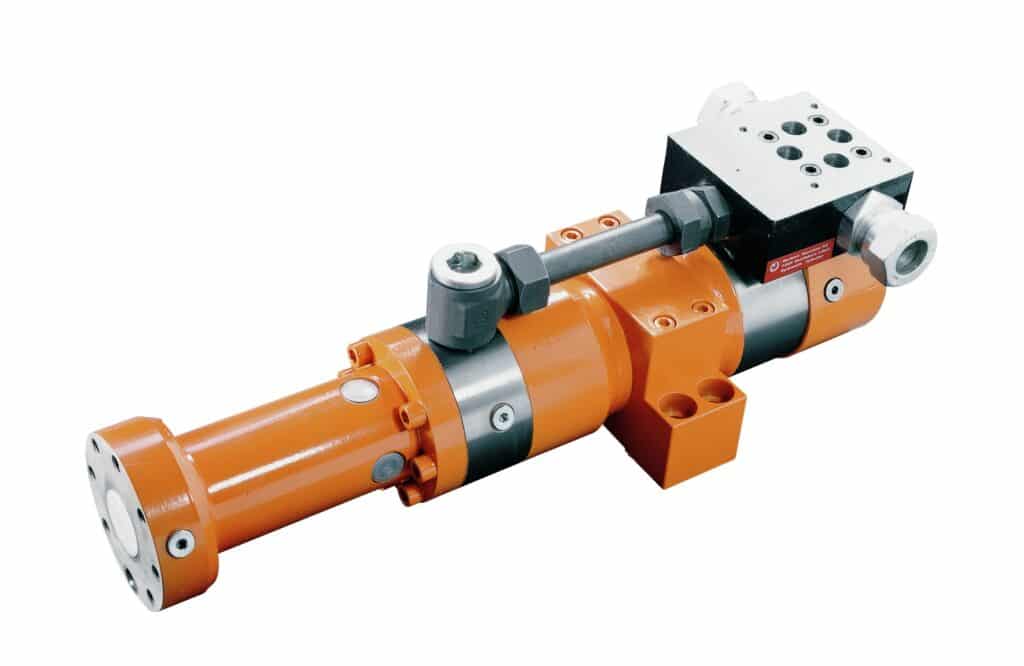

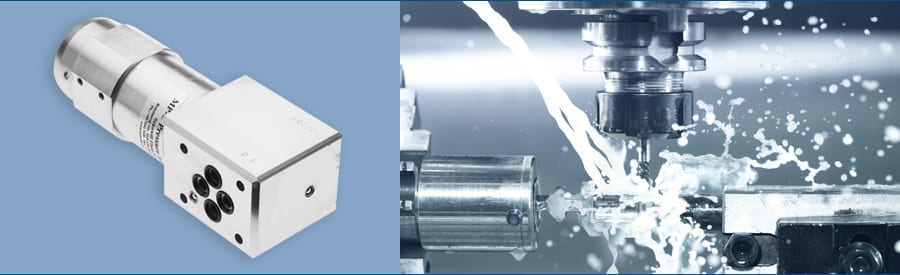

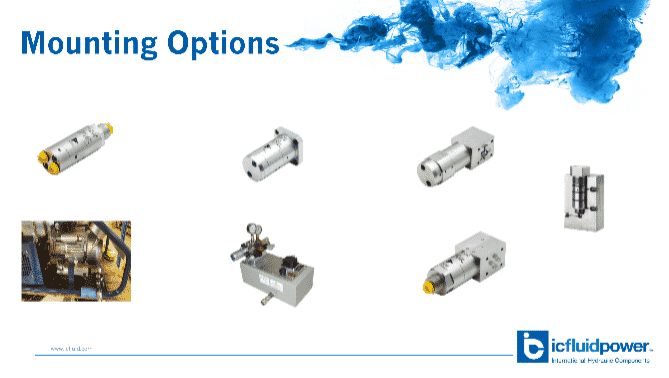

The design of the intensifiers is very compact, and they are very easy to install. They are offered as in-line models, which fit standard pipe clamps used throughout the industry. They can also mount as flange mounts. There are options for cetop models and as cartridge type intensifiers. For this application we will be choosing to mount our intensifier in-line.

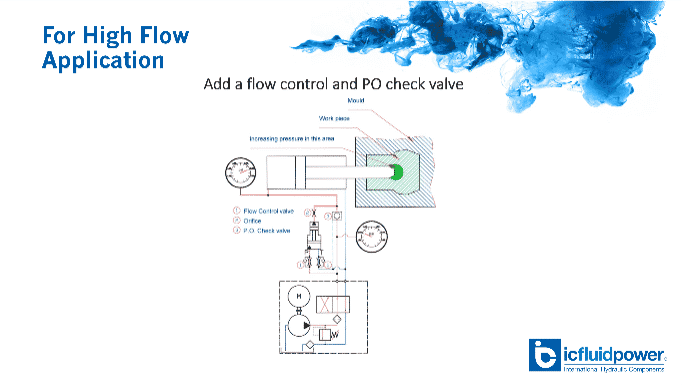

In high flow applications, we may need to restrict the flow to keep from damaging the intensifier. You can do this by adding a flow control and a p.o. check valve to prevent excess flow.

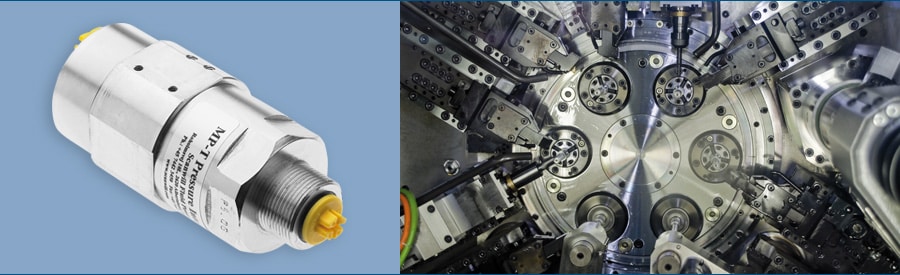

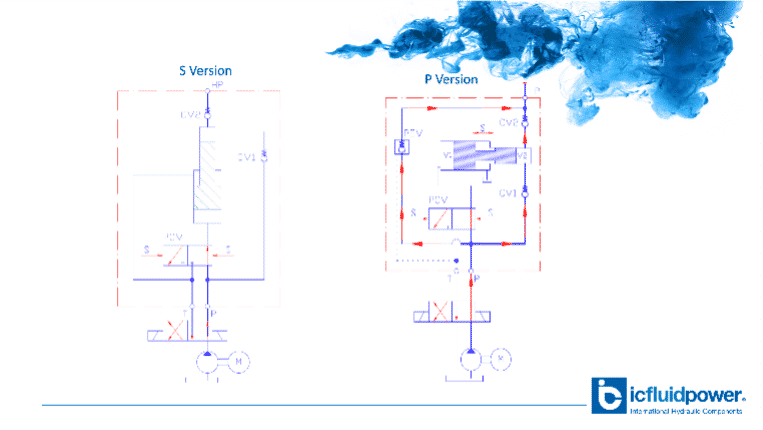

Once the pressure intensification is reached, we are going to need to know how you are going to plumb the return flow. There are two versions. If you plan to plumb around the intensifier – you will need an S-Version. If you are going to allow the return flow from the component to flow through the intensifier – you will need a P-Version. The P version has a POV valve integrated into the intensifier.

So, we have an in-line application that we need to boost to 5000 psi from a current pressure of 2,500 psi. The system has a flow rate of 13 GPM and the return line will be plumbed through the intensifier. We will need a MP-L-P-2.0. The L in the MP-L stands for large flow intensifier series. We are using the large series because we have a high flow rate of 13 GPM. The P designates a POV to be included because we are routing the return line through the intensifier. If we were routing the return around the intensifier that letter would be S. And the 2.0 designates the intensification ratio.

ScanWill is a supplier and pressure intensifier manufacturer for various applications including construction, mechanical, marine, and industrial.