HYDRAULIC PRESSURE INTENSIFIERS – TROUBLESHOOTING

Hydraulic Pressure Intensifiers – Troubleshooting

Most problems concerning the ScanWill Pressure Intensifiers are caused by the following 7 factors:

1. Contamination of the Fluid

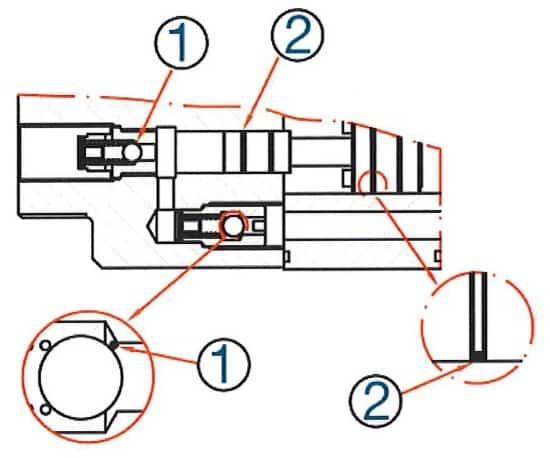

If the oil is contaminated it has the possibility of 1, particles could be caught between the seat and the ball check valves. This will result in the intensifier continuously working but will not be able to build pressure.

Also, particles in the oil may be moved along the ground bores 2, and destroy the surface, which will lead to internal leakage through the pistons.

To avoid these problems, a 10µ pressure filter should be added before the intensifier.

2. Large volume under pressure

In applications with a large volume of flow under pressure, the activation of the internal p.o. check valve will cause a very high flow rate in a very short time inside the intensifier.

This high flow rate might be many times the max allowable flow rate of the intensifier and due to the compact design of the ScanWill intensifiers, the flow passes by the internal check valves which will be damaged due to excess flow.

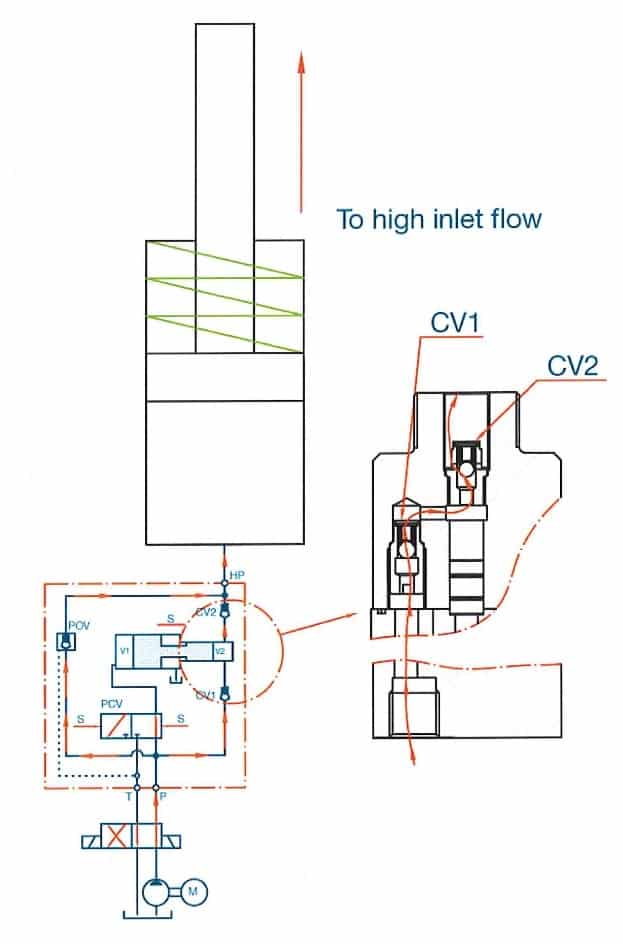

3: Too high of an inlet flow

If the maximum flow rating is exceeded, the internal check valve springs will be compressed too much, and the check valve will be damaged. In addition, excess flow will cause the piston speed to be too high and cavitation may occur. To avoid these problems the inlet flow for both the T and P should be controlled.

4: Too high of an inlet pressure

Exceeding the max inlet pressure for the ScanWill intensifier will result in the screws holding the body parts together to stretch. This will result in the static O-rings between the body parts to be pushed out, and the intensifier will leak. Also, if the screws stretch, the internal leakage will increase, and the intensifier will not be able to increase pressure.

5. Heat

In situations where you have excess heat, the fluid could get thin and lose its lubricity. This will result in the pistons inside getting stuck in the bores and the intensifier will not work. To avoid this, sufficient cooling should be applied. You should also set up your circuit to have your return oil route back to tank when relieving pressure.

6. Return pressure

The ScanWill intensifiers intensify the differential pressure between the P and T inlet ports. In applications with high back pressure in the T line, the expected end pressure might not be obtained. In these situations, a separate T line for the intensifier should be considered.

7. Air in the oil

Air in the oil is unwanted. This will result in the damage of internal parts such as valves and pistons and the performance of the intensifier will be unpredictable. To avoid this the system should be designed so no pockets of trapped air can occur.

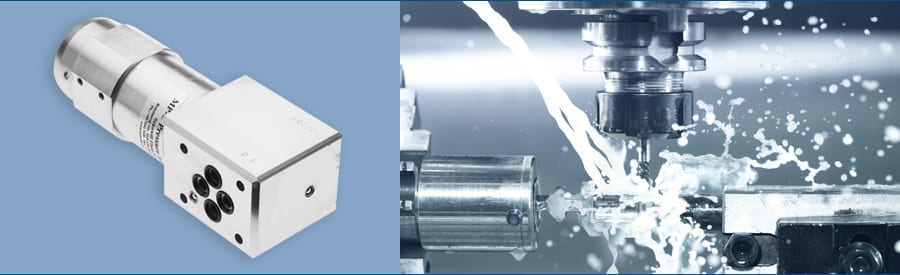

ScanWill is a supplier and pressure intensifier manufacturer for various applications including construction, mechanical, marine, and industrial.