Welcome to IC-Fluid Power

Global Hydraulic Component Sourcing

IC-Fluid Power brings the world to you by sourcing off-the-shelf and custom hydraulic components from around the globe. Almost overnight, your options for purchasing high-quality, off-the-shelf and custom hydraulic components triple, maybe even quadruple.

Global Sourcing

Best-in-class Hydraulic Components

Providing you with easy access to high-quality and many times unique, German and European-sourced hydraulic components.

Reliable Supply

Extensive On-Hand Parts Inventory

Reduce the cost and time to source the world on your own. Increase your capital, reduce risk, and improve cost/benefit ratios.

Customized Solutions

Experts in Speciality Hydraulics

Providing you with strategies to source hydraulic components, and engineering and hydraulic component design.

Trusted Partners

International Hydraulic Group

Our success comes from the long- standing relationships at the foundation of our supply chain that allow us to link you to global and domestic partners.

Product Categories

Flow Dividers

Heat Exchangers

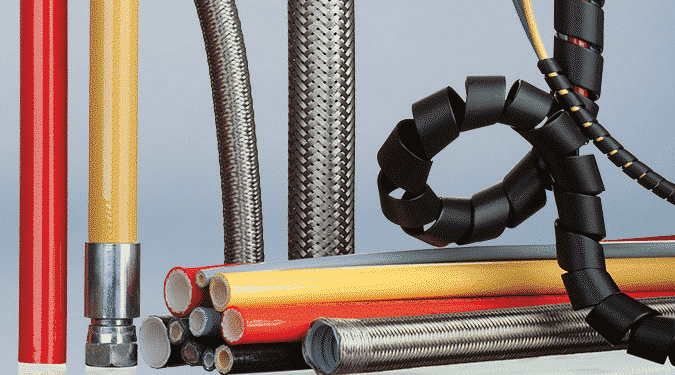

Hoses

Hydraulic Accessories

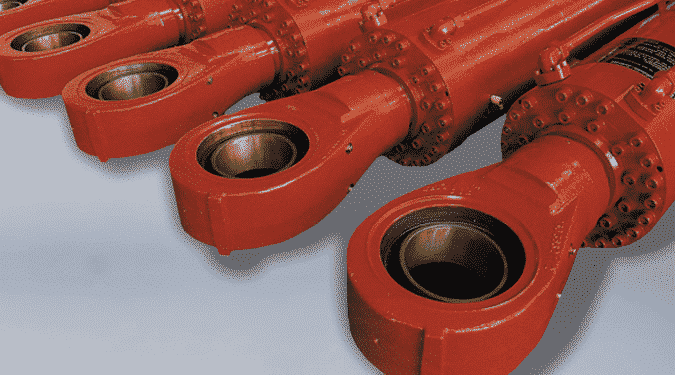

Hydraulic Cylinders

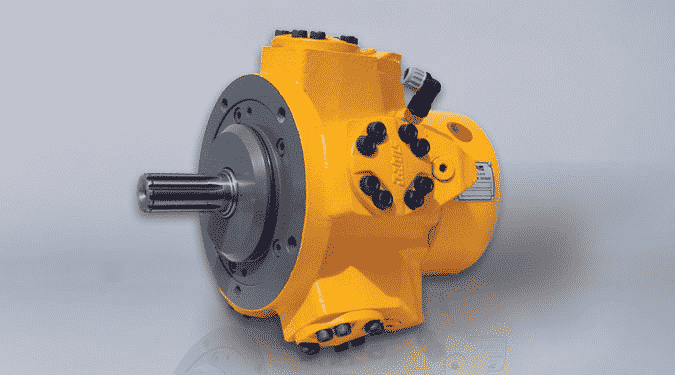

Hydraulic Motors

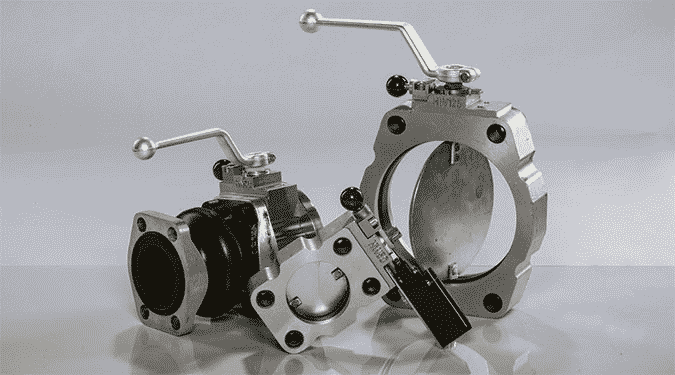

Power Unit Products & Valves

Press Products

Pressure Intensifiers

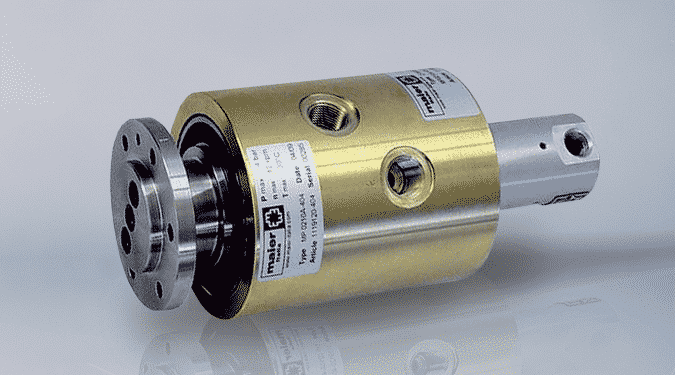

Rotary Actuators

Rotary Unions

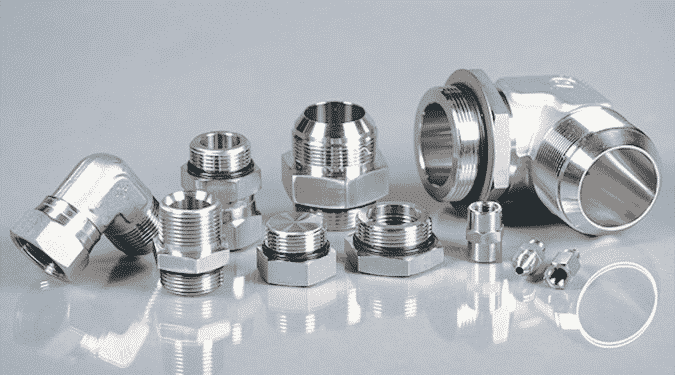

Stainless Steel Fittings

Valve Actuators

Featured Products

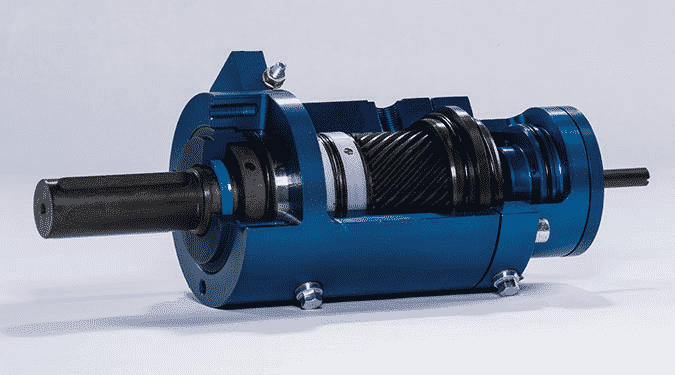

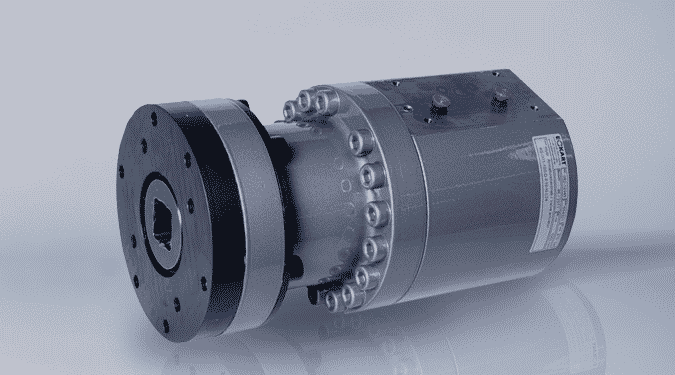

Rotary Actuator

Through the constant developments made by Eckart GmbH engineers, and the use of high quality materials, Eckart GmbH rotary actuator components provide durability and dependability. With an Eckart GmbH rotary actuator, you can profit from their experience. More than 70% of these actuators are custom-designed to meet specific customer needs. Tell us about your project and we will present you with a customized optimum solution.

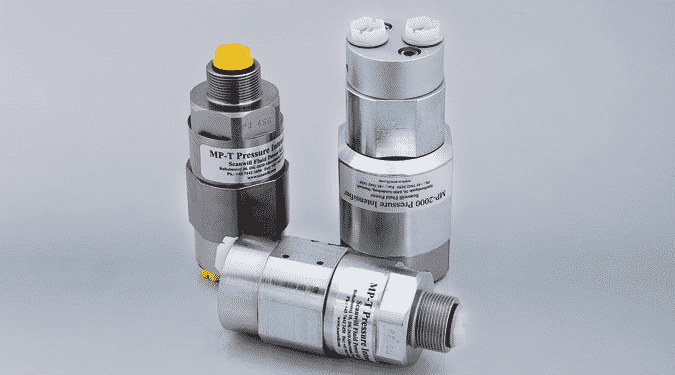

Pressure Intensifiers

Without doubt hydraulic solutions can be said to operate with immense force. Whoever occasionally needs even more force, albeit for only a brief spell and therefore does not want to reconfigure the complete hydraulic system to suit, can now save themselves the bother, if they opt to install a pressure intensifier.

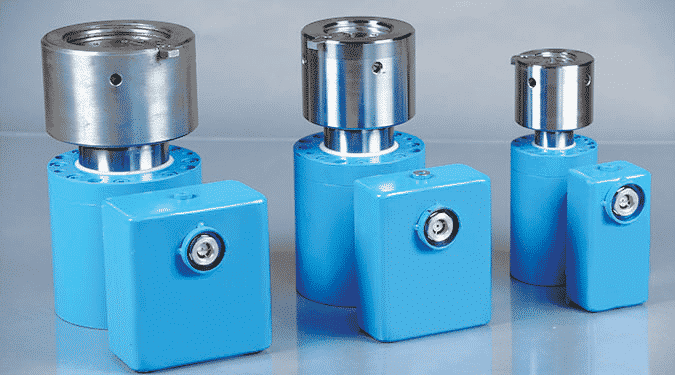

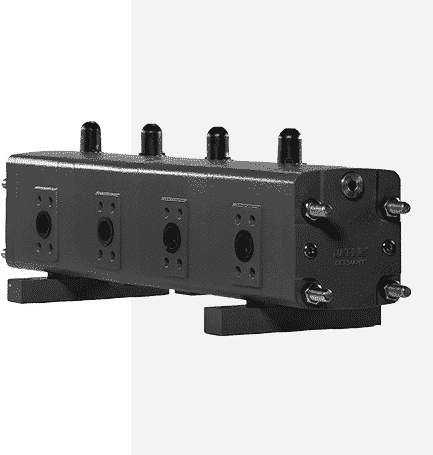

Flow Dividers

Available through Jahns, our Flow Dividers come in different types such as Hydraulic Gear Type, Radial Piston, Volumetric, and Rotary. Flow Dividers utilize flow from a single input source and divide it into multiple different outputs. Ranging from 2 to 12 section dividers with various flow rates, these flow dividers come in multiple sizes for numerous applications.

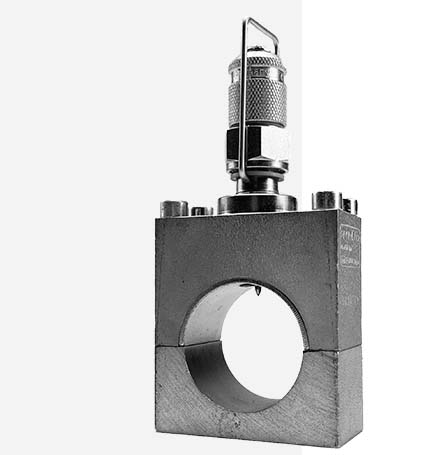

Serv-Clip

The Serv-Clip® tube measuring connection is used to add a test point on an existing hydraulic circuit within 3 minutes. There is no need for cutting pipes, even if the system is pressurized to 9,100 psi (630 bar). The Serv-Clip® has the ability to carry out various measurements: pressure, flow rate, leakage, temperature, oil sampling or connect a variety of measuring devices.

Featured Articles

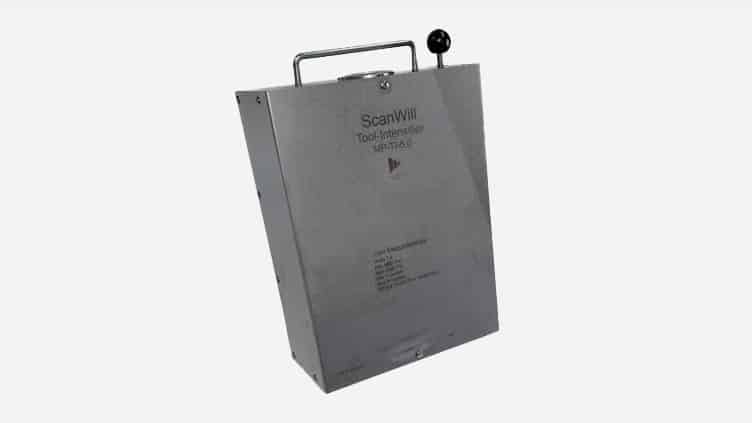

New Tool Intensifier Safely Pressures Your Hydraulic Tools

The tool intensifier is a device that utilizes the existing hydraulic tool circuit on utility trucks and boosts it to 10,000 psi. This allows you to use large crimping tools without the need for a separate electric or gas engine HPU. The pressure is intensified with a reciprocating piston that operates at full flow until the crimper bottoms out. Once the tool has bottomed out, the intensifier senses this and starts intensifying the lower pressure flow . . .

In this article, we will talk about the new tool intensifier benefits, applications, and how it works.

IC Series Rotary Actuators Designed as Ready Drop-ins

The IC Series can be used as a drop-in replacement to Helac’s rotary actuators. This series offers a cost-effective solution with faster lead times (22-26 weeks) or . . .

dx

What are Gear Flow Dividers and How are They Used?

A flow divider is used to divide flow from a hydraulic pump into two or more output sections. Depending on the application, flow dividers can distribute flow into unequal or equal parts . . .

News and Events

Industrial Vehicle Technology Expo

Booth 615

August 21-22 , 2024

in Chicago, Illinois

T&D World Live

Booth 204

October 1-3, 2024

in Atlanta, Georgia

Lineman’s Rodeo

Booth 25

October 17-18, 2024

in Overland Park, Kansas

Automotive Testing Expo

October 22-24, 2024

in Novi, Michigan

IDCO Expo

November 4-6, 2024

in Louisville, Kentucky