POWER UNIT PRODUCTS & VALVES — CHECK VALVES

Power Unit Products & Valves – Check Valves

Check valves block an oil flow in one direction and allow it in the other direction. They are a type of shutoff valve. The check valve is inserted when an oil flow shall be allowed in one direction only. Meanwhile, the usage of check valves prevents backflow of the fluid.

Advantages at a Glance:

- Patented Spherical Shell

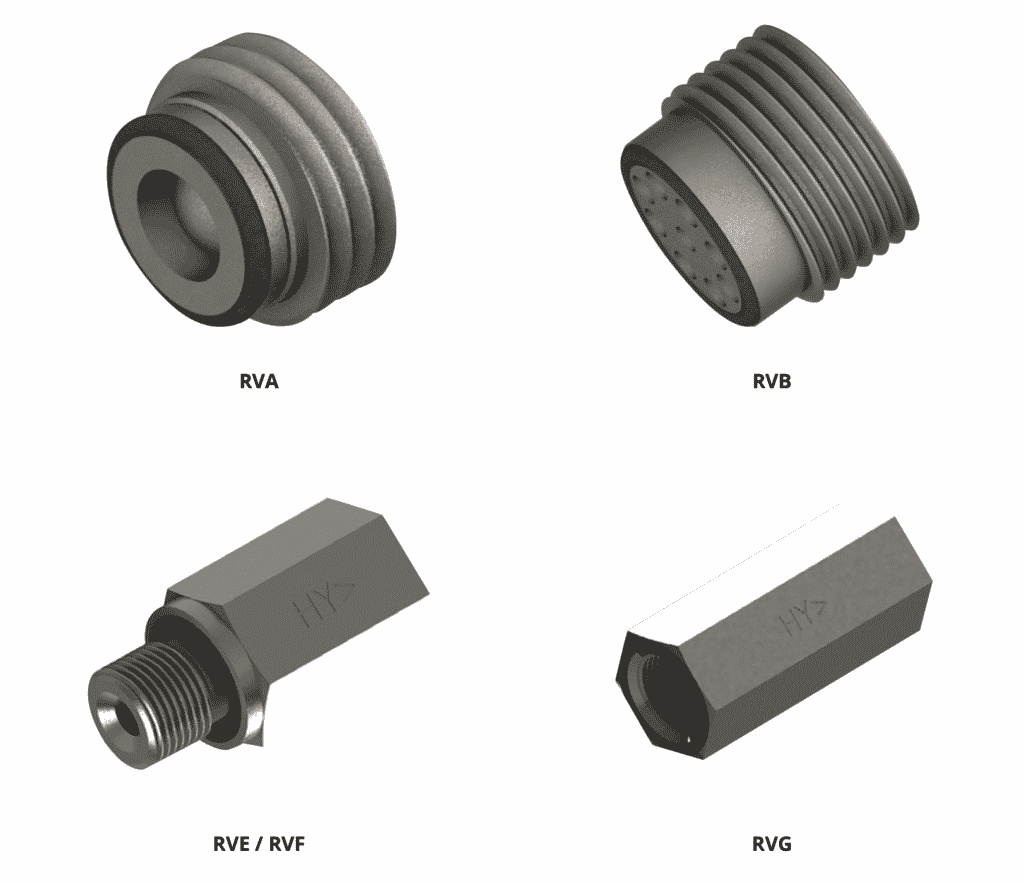

- Available as Screw-In or Caged Version

- Nominal Size 1/16-1/8-1/4-3/8-1/2-3/4

- Working Pressure 10,000 PSI

- BSP or Metric Thread

The HYTORC-check valves are available with a screw-in or caged design. Even so, both designs can be obtained in two flow directions: with the screw-in direction closed or with free-flow. The spherical cap remains reliably tight in every position, in case of multiple switching cycles and under severe stress.

The HYTORC check valve easily screws into a regular hole (Dimensions screw-in drill). The screw-in check valves are sealed through an edge sealing which is turned to the cage. The edge sealing, together with the drill draft, forms a gap-free chamber for the O-Ring. The gap-free chamber and the O-Ring are repeatable sealing.

The valve is made of a high-strength hardened steel. Moreover, the ball seat is specially treated and the patented spherical shell is manufactured with a high tensile hardened and polished ball bearing ball. Thus, the design of the check valves is compact and economical which saves space and offers simple installation.

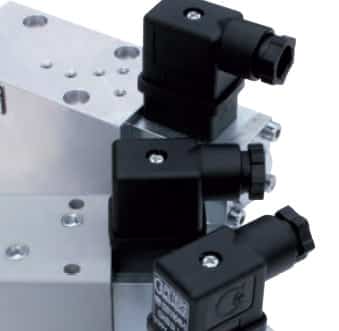

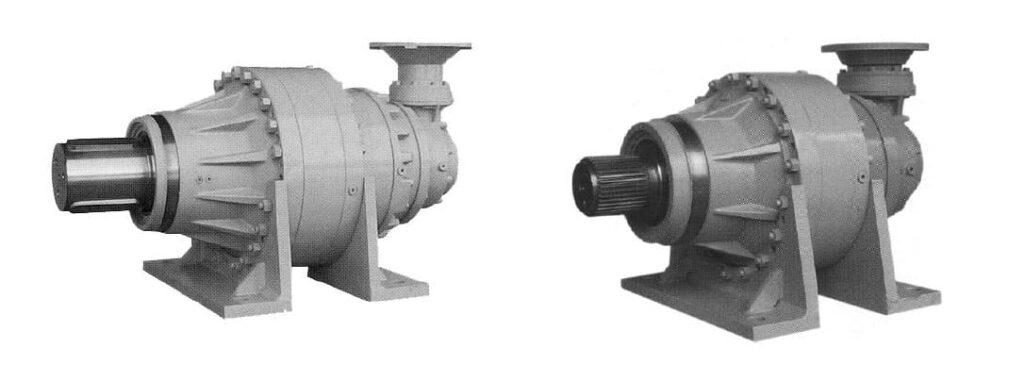

Hytorc-HydroWer is a supplier and power unit accessory and valve manufacturer for various applications including construction, mechanical, marine, and industrial.