A Domin Hydraulic Servo Valve US Supplier & Distributor

IC-Fluid Power, Inc. is a supplier, representative, and distributor of Domin hydraulic servo valves. As the sole regional supplier and one of the few national suppliers in the US, we import in bulk from their manufacturing plant in the United Kingdom to pass the savings and quick lead times to you. Most of their models are kept in stock in our Ohio warehouse to cut down on transportation costs and keep shipping times short.

Domin’s Background

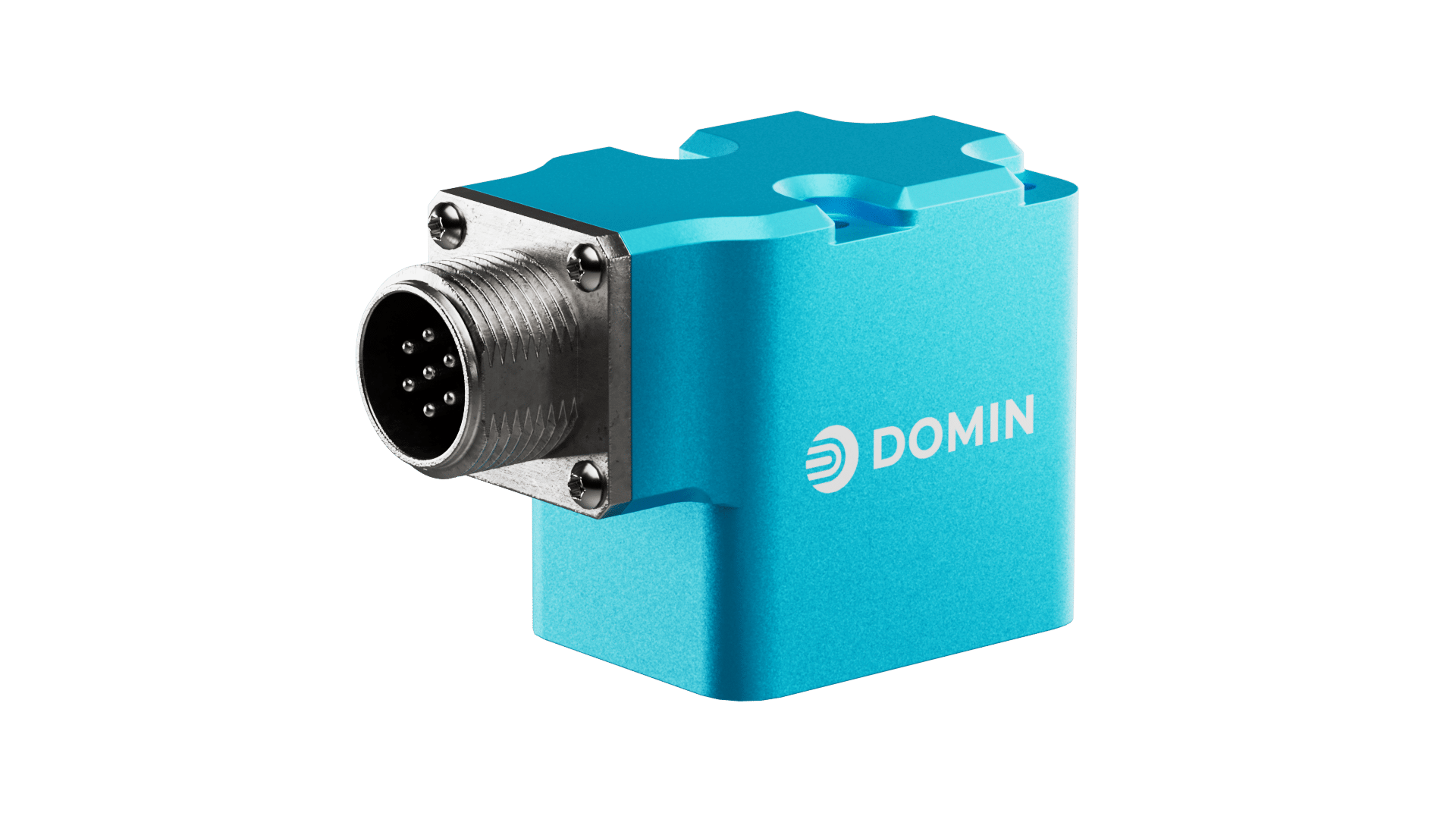

Headquartered in Bristol, England, Domin is setting a new standard in hydraulics with advanced servo valves that combine the best qualities of traditional two-stage valves and direct-drive valves. Domin is doing more than just making servo valves. They are redefining how the world uses energy, reinventing wasteful manufacturing processes by using technologies such as 3D printing and additive manufacturing.

Domin’s Revolutionary Valve Technology

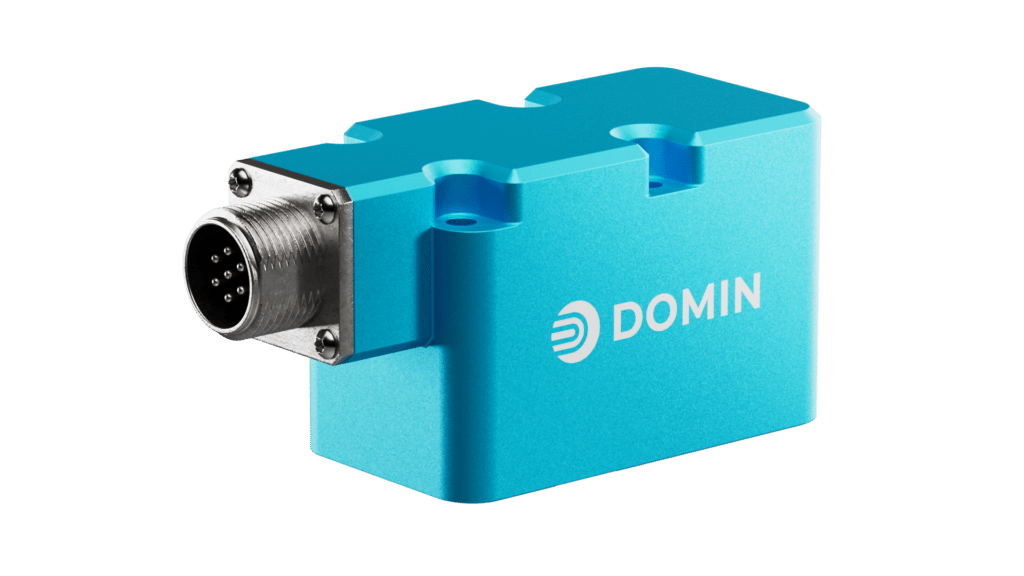

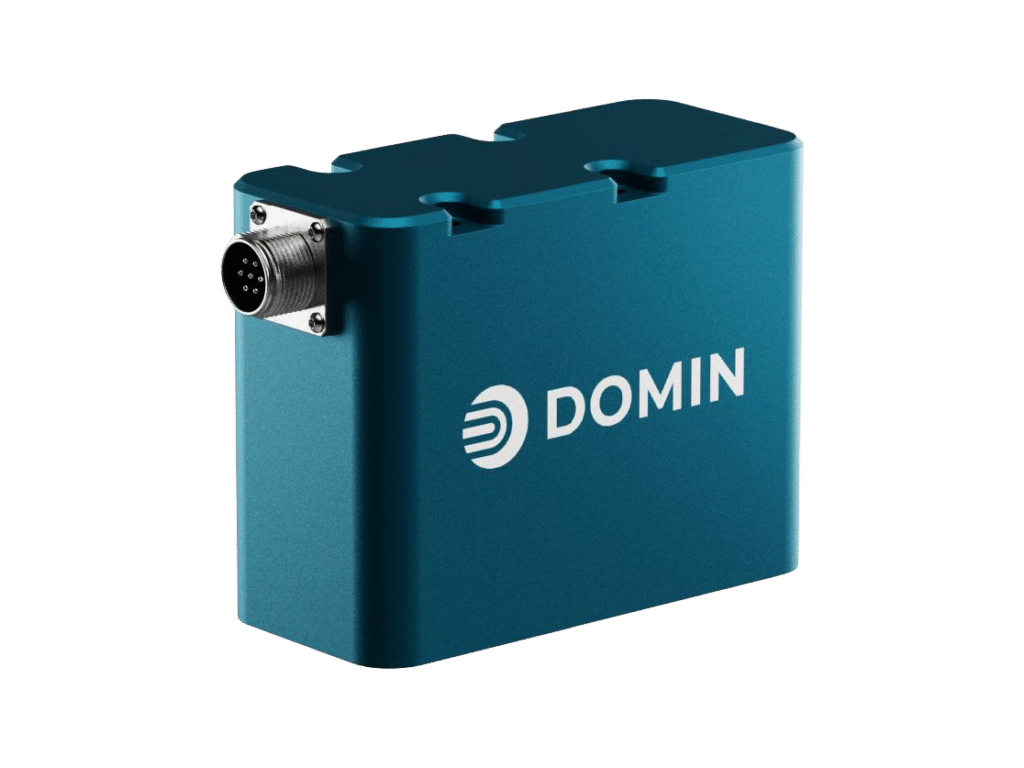

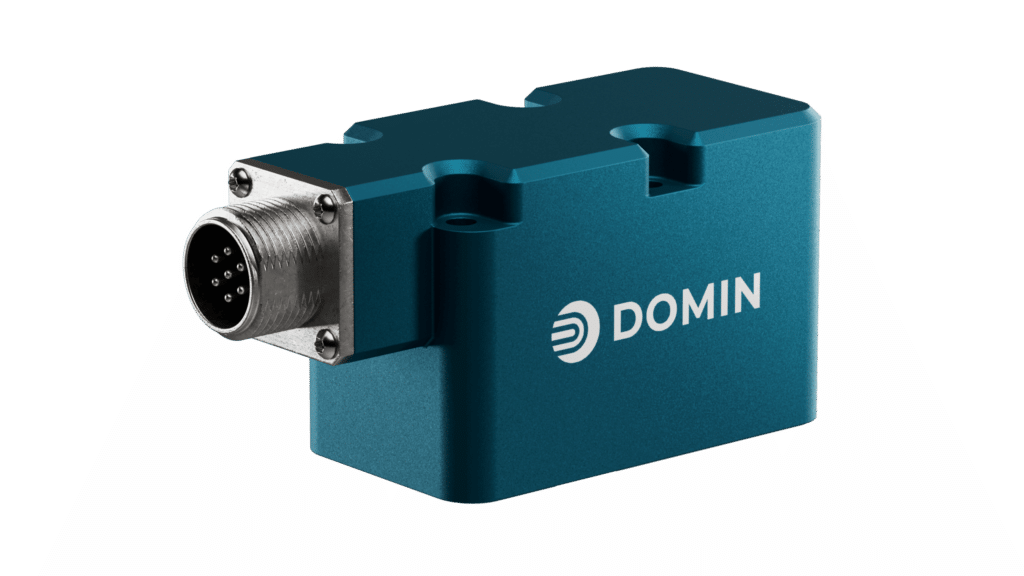

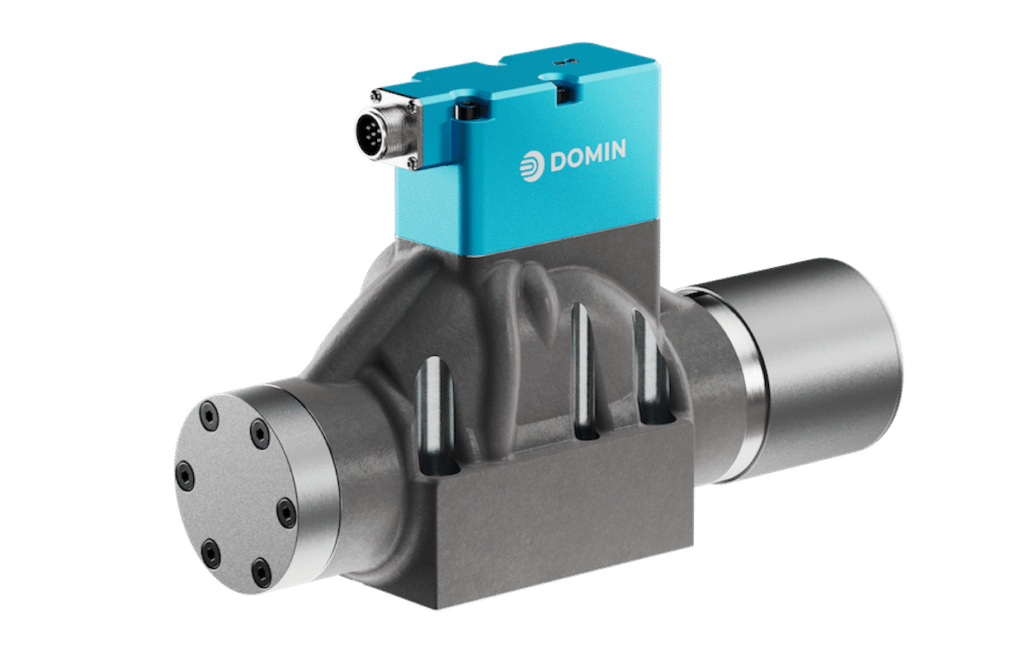

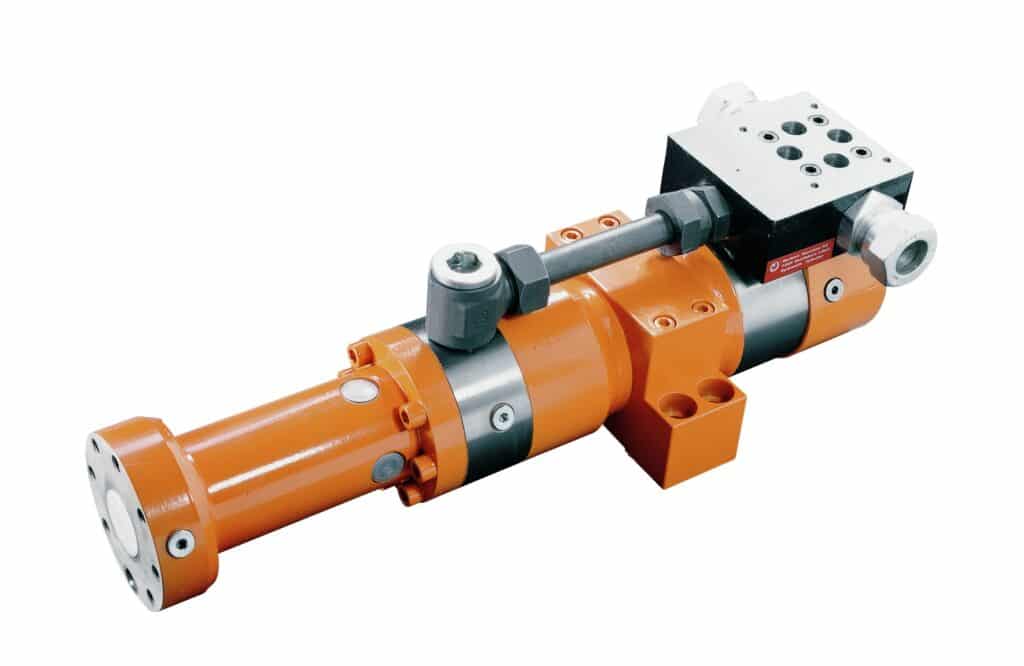

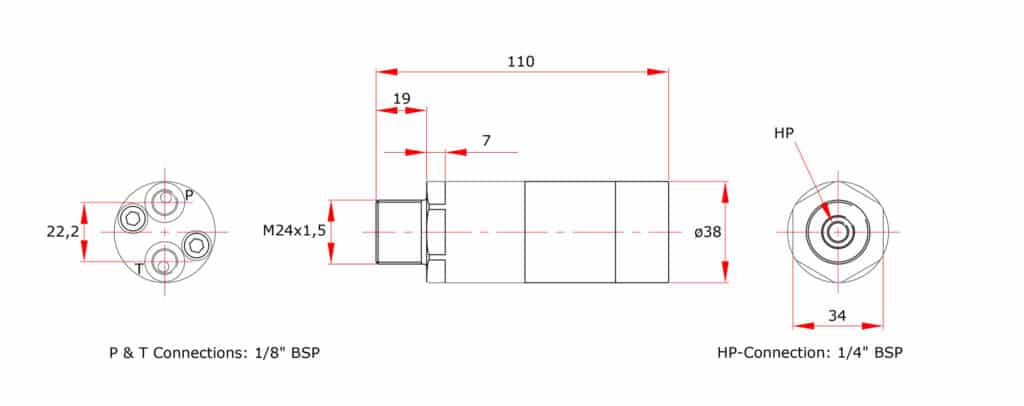

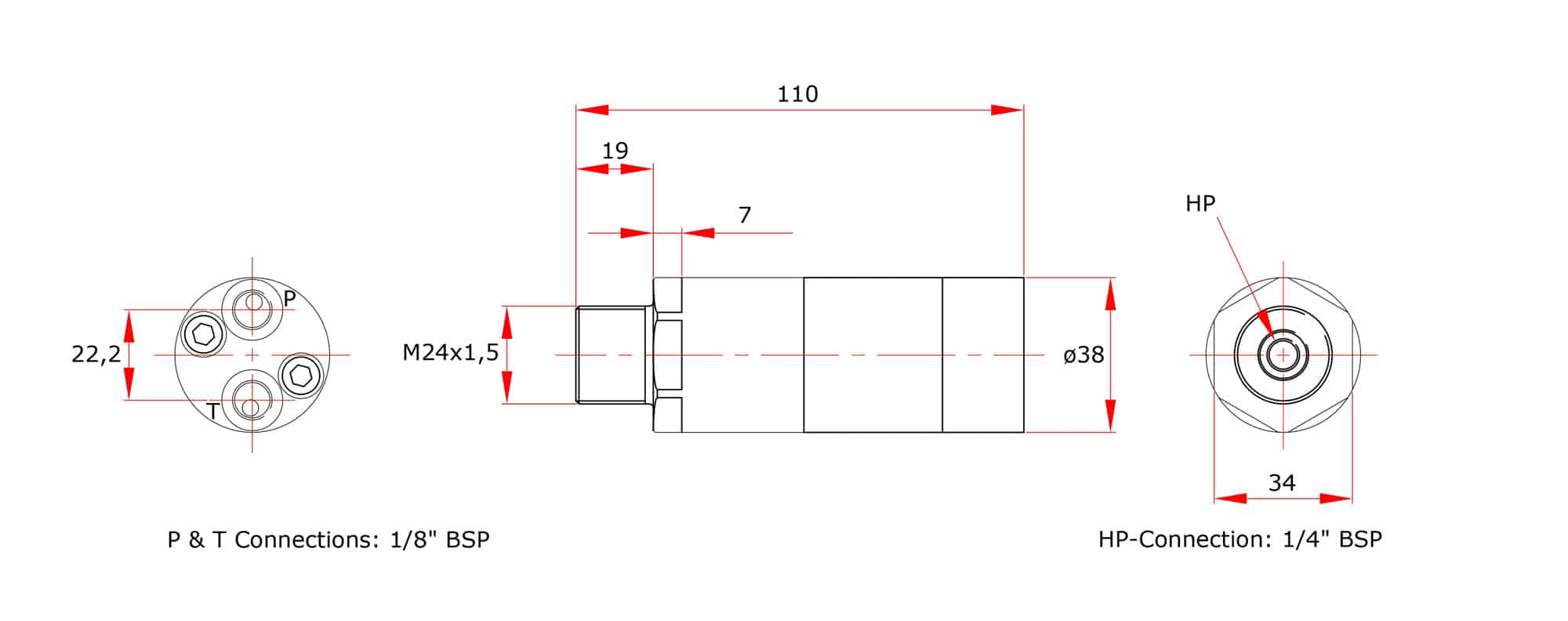

The Domin Hydraulic Servo Valve

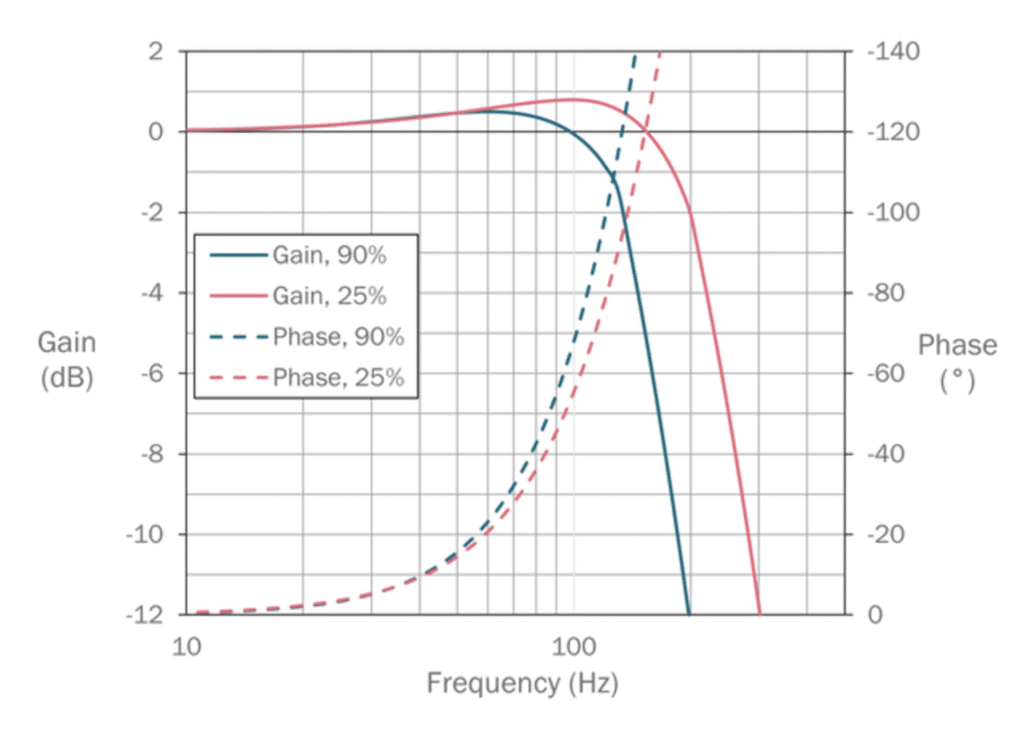

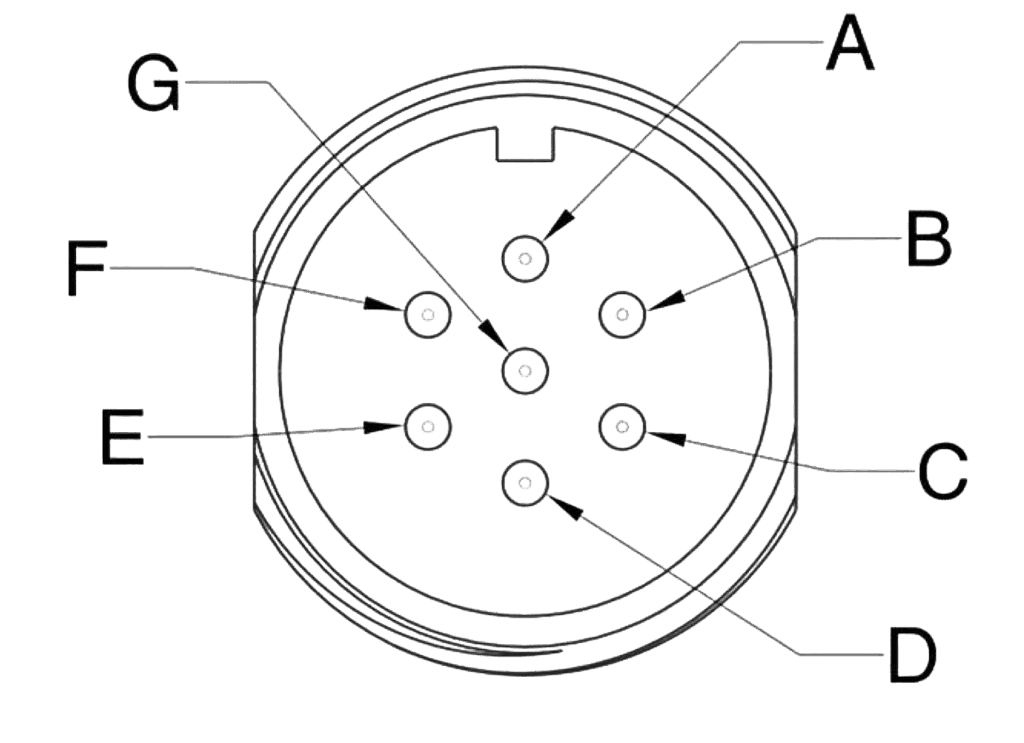

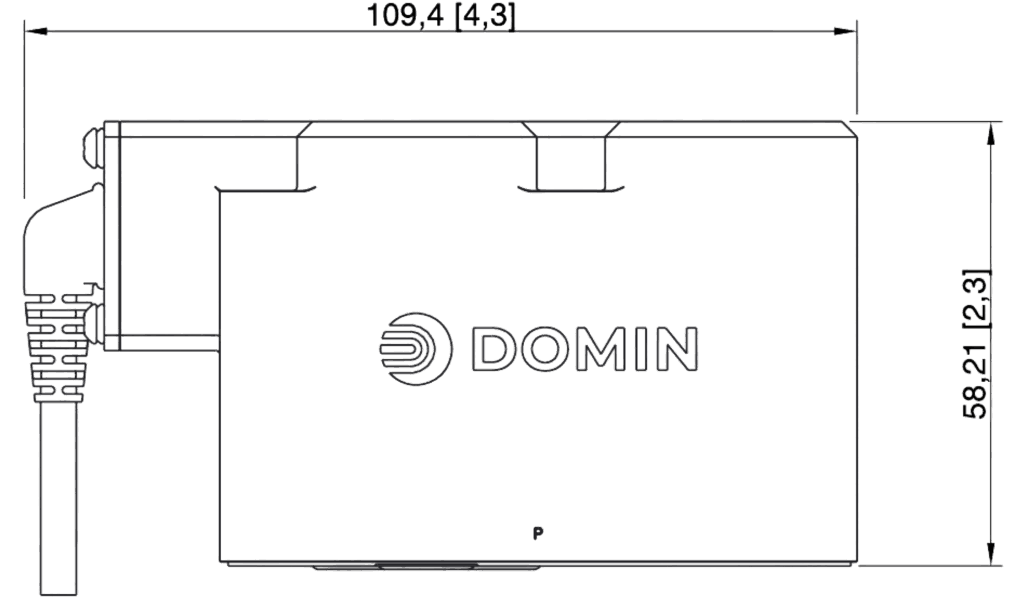

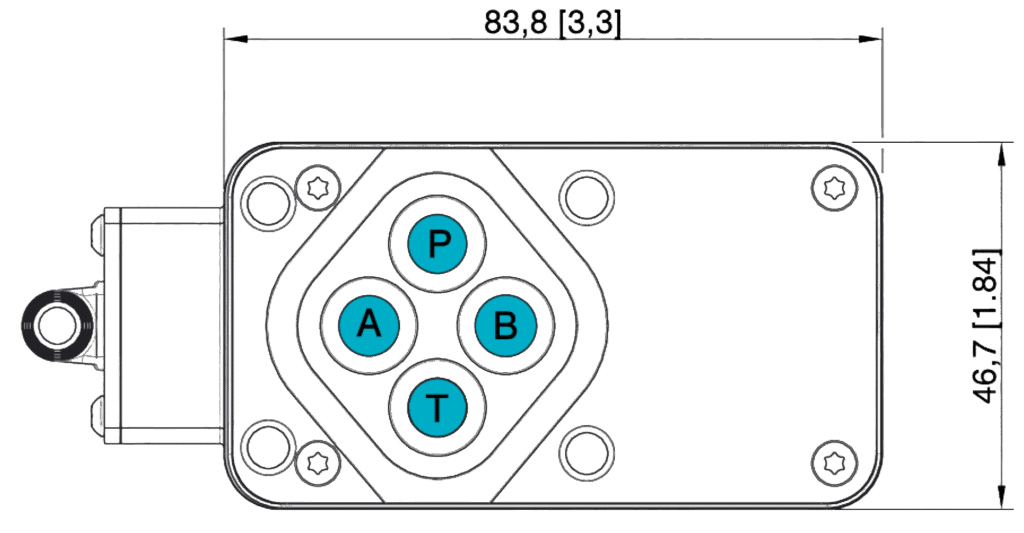

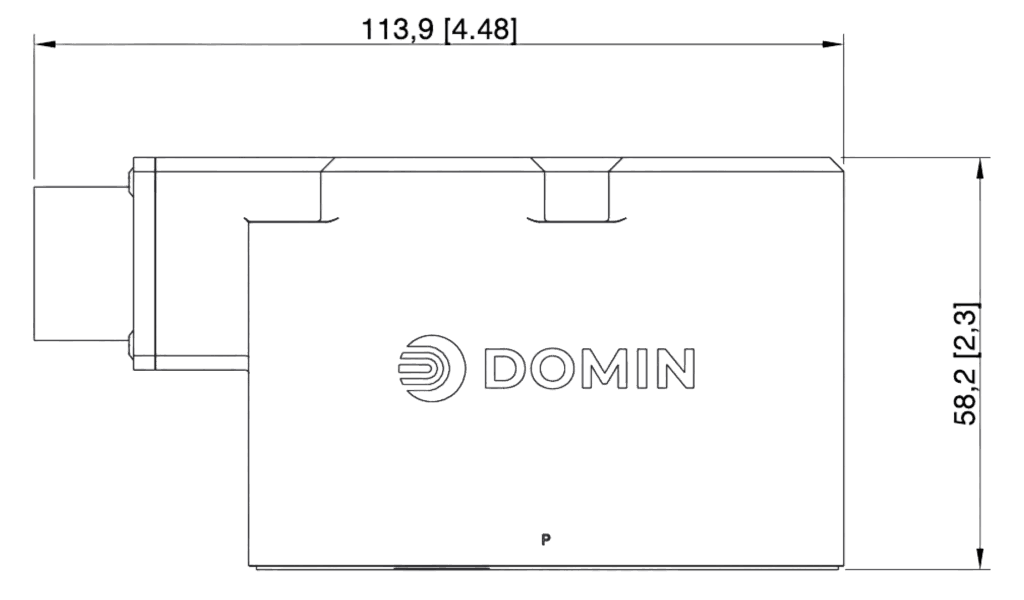

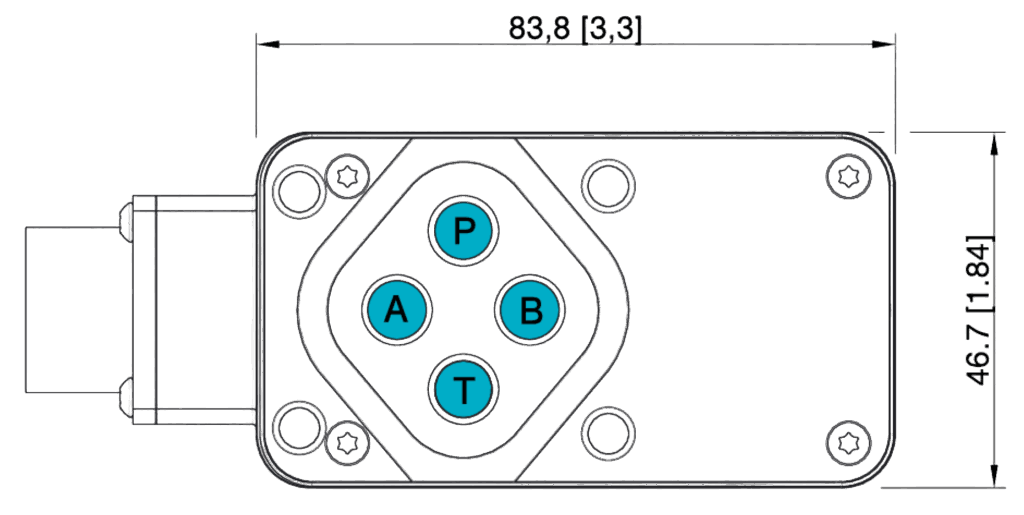

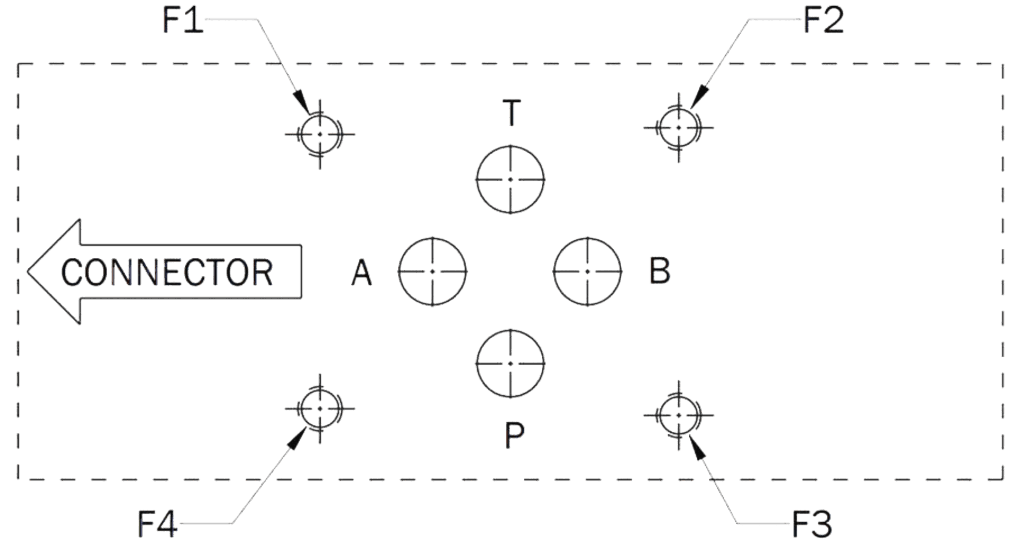

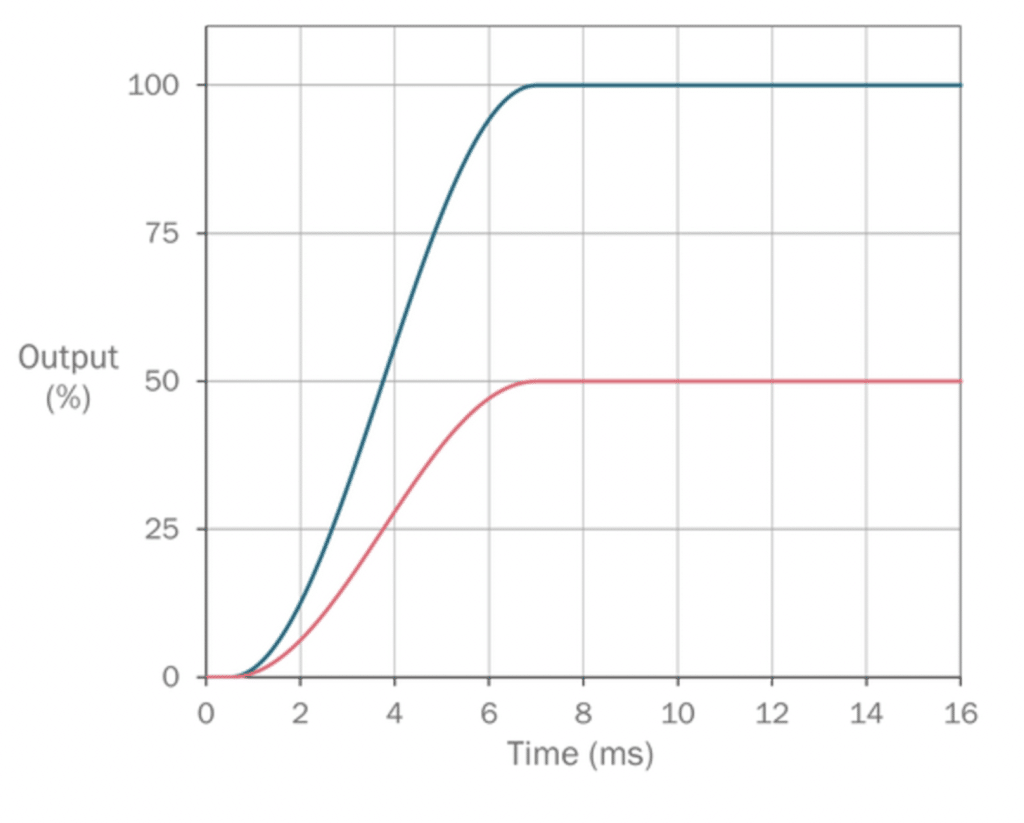

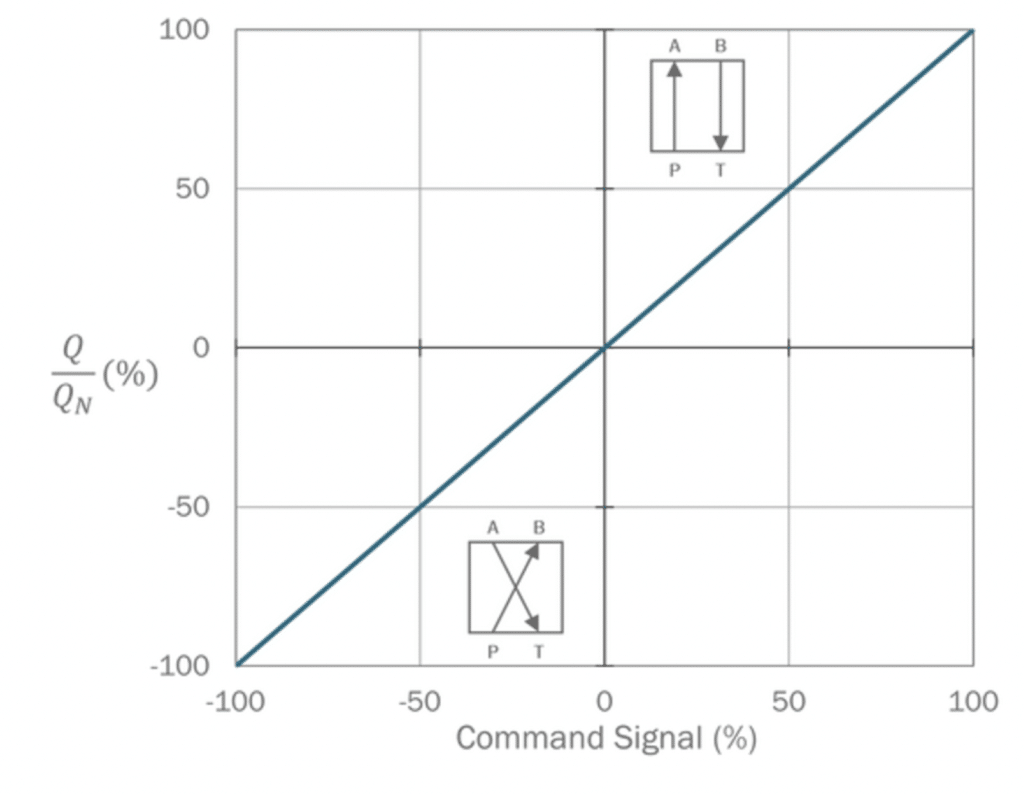

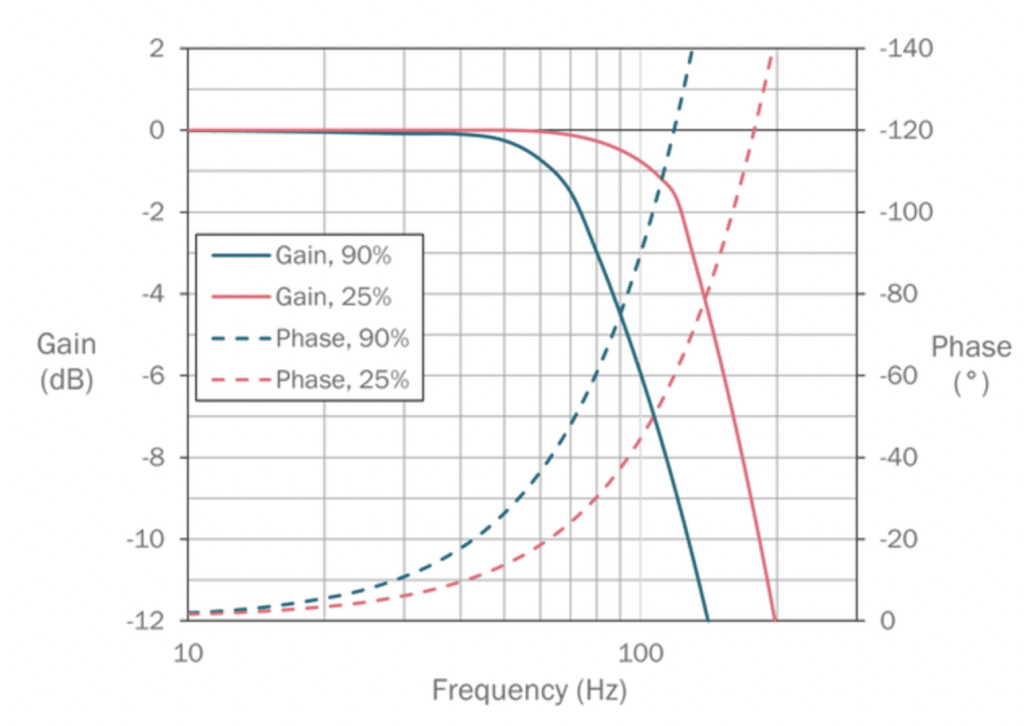

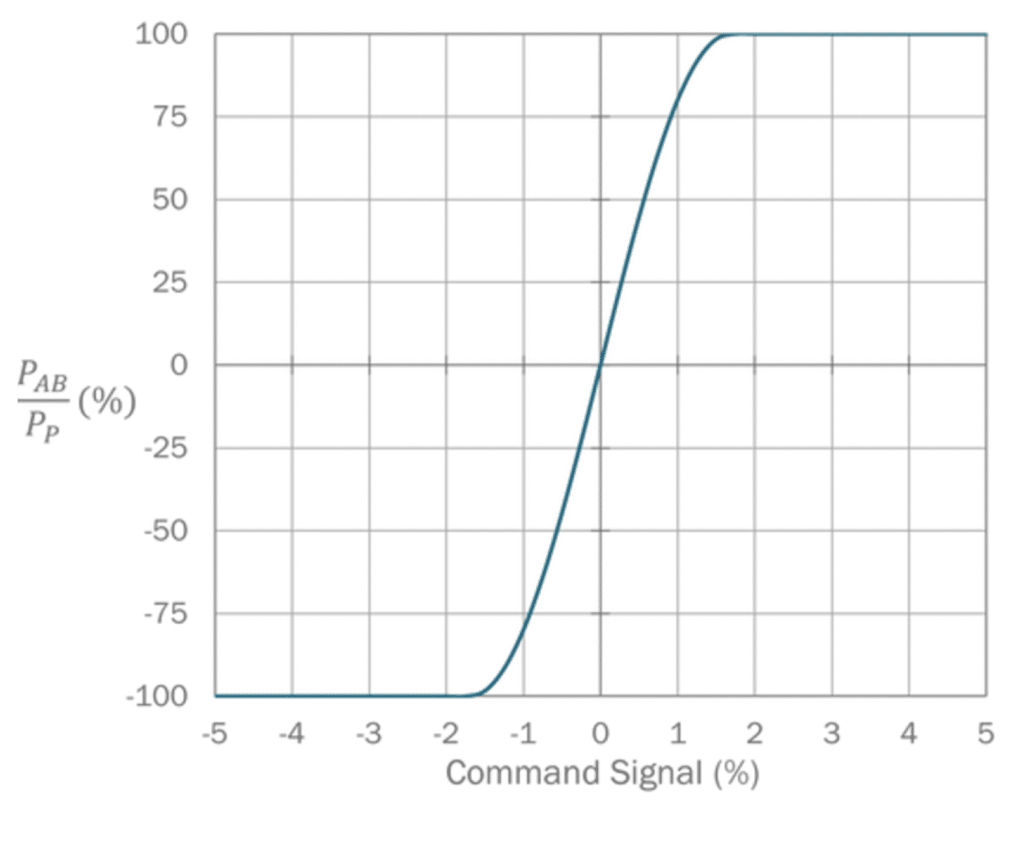

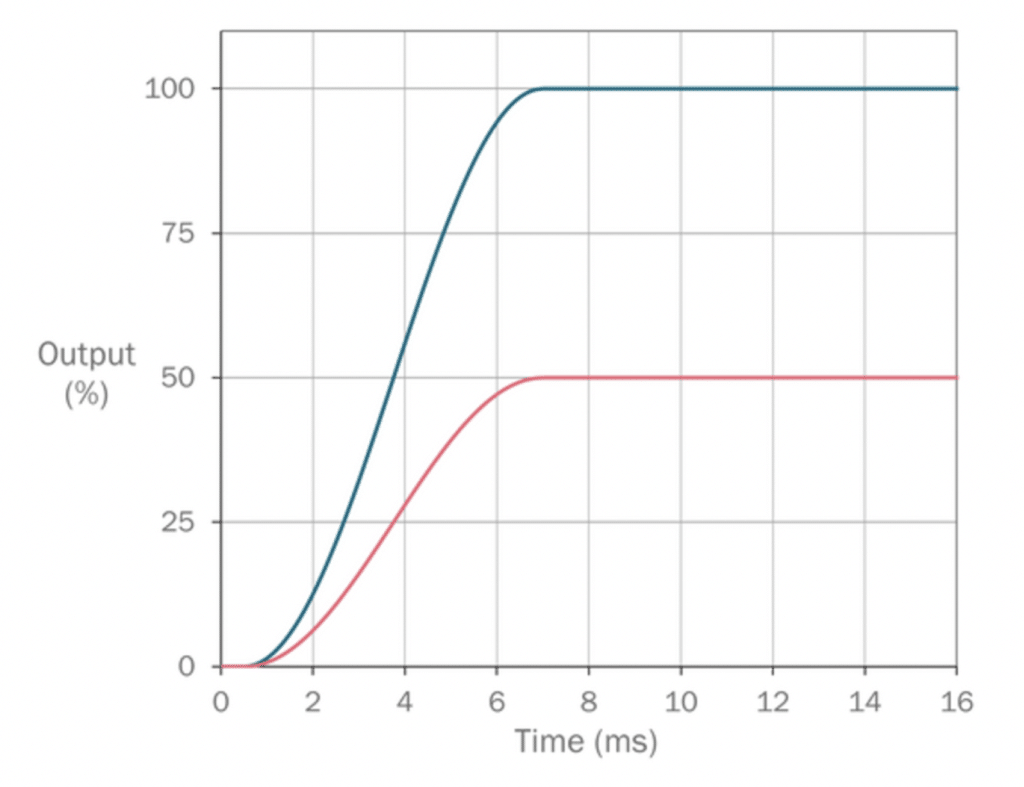

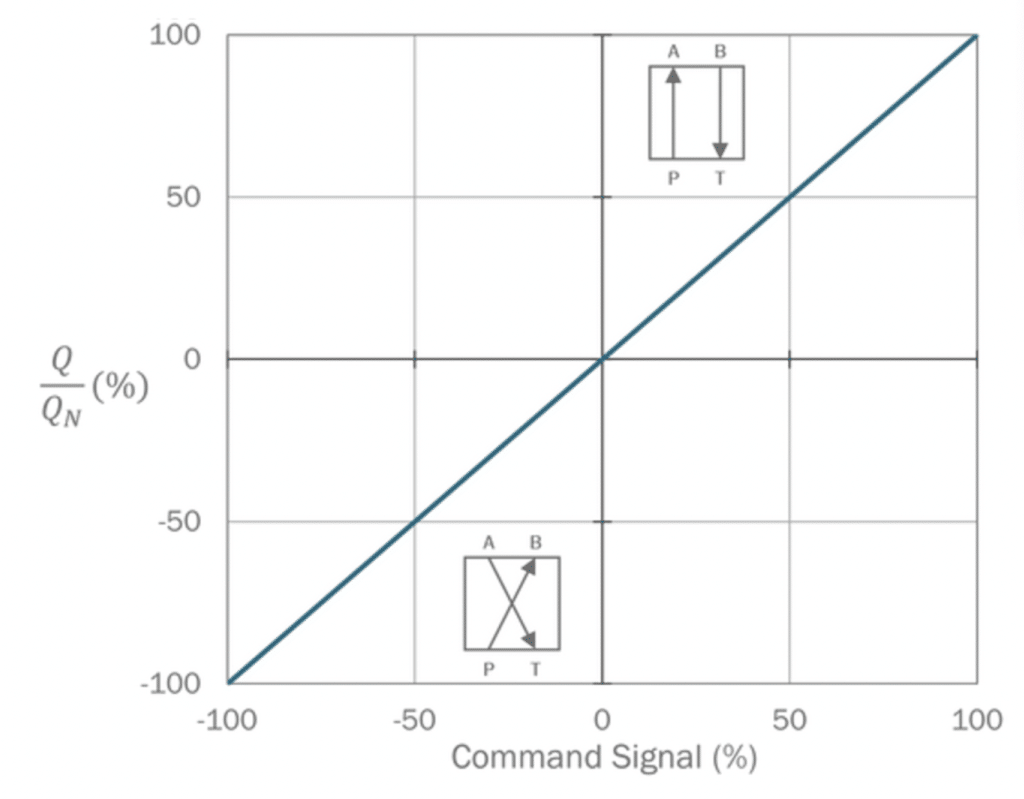

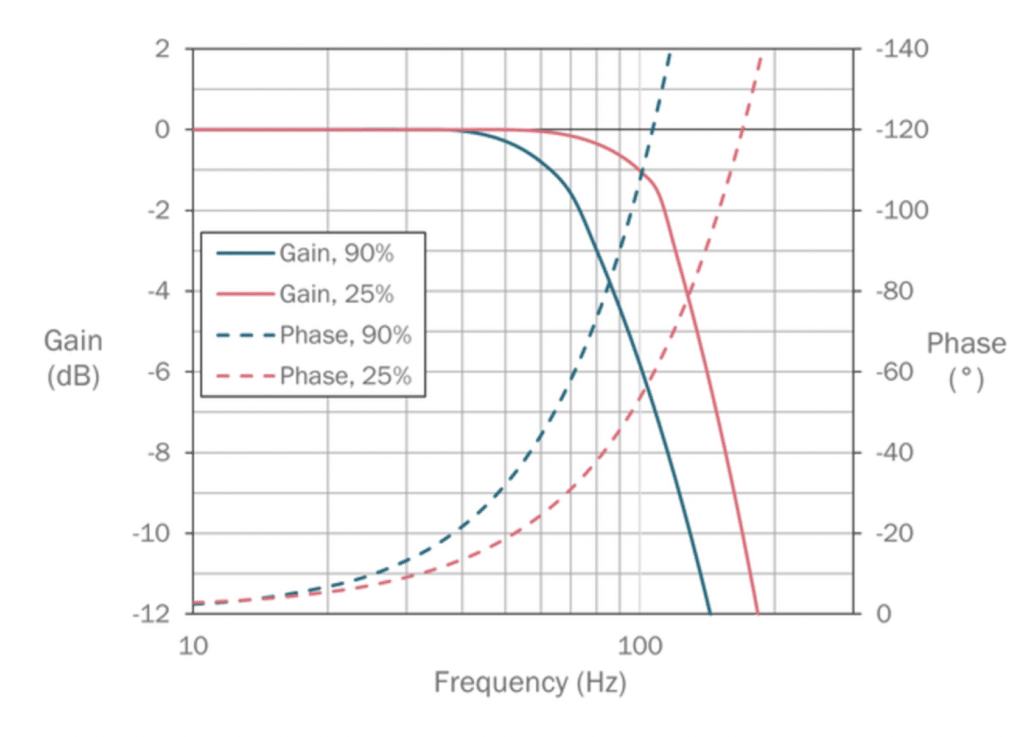

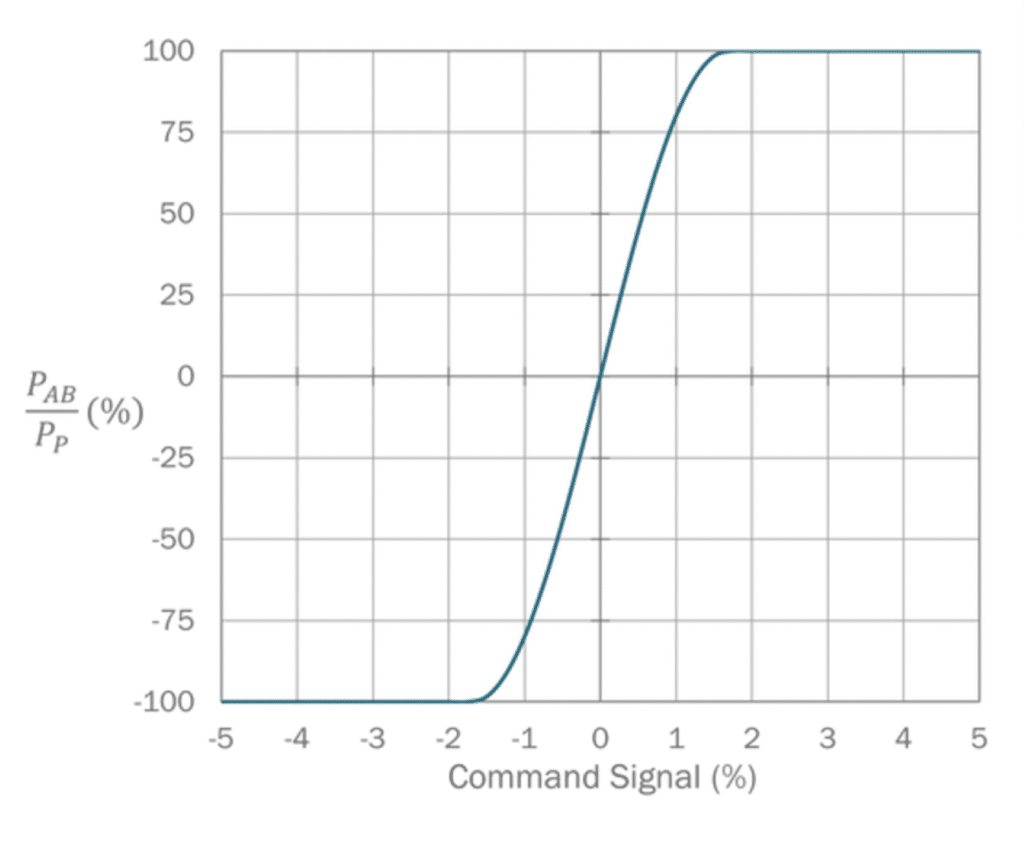

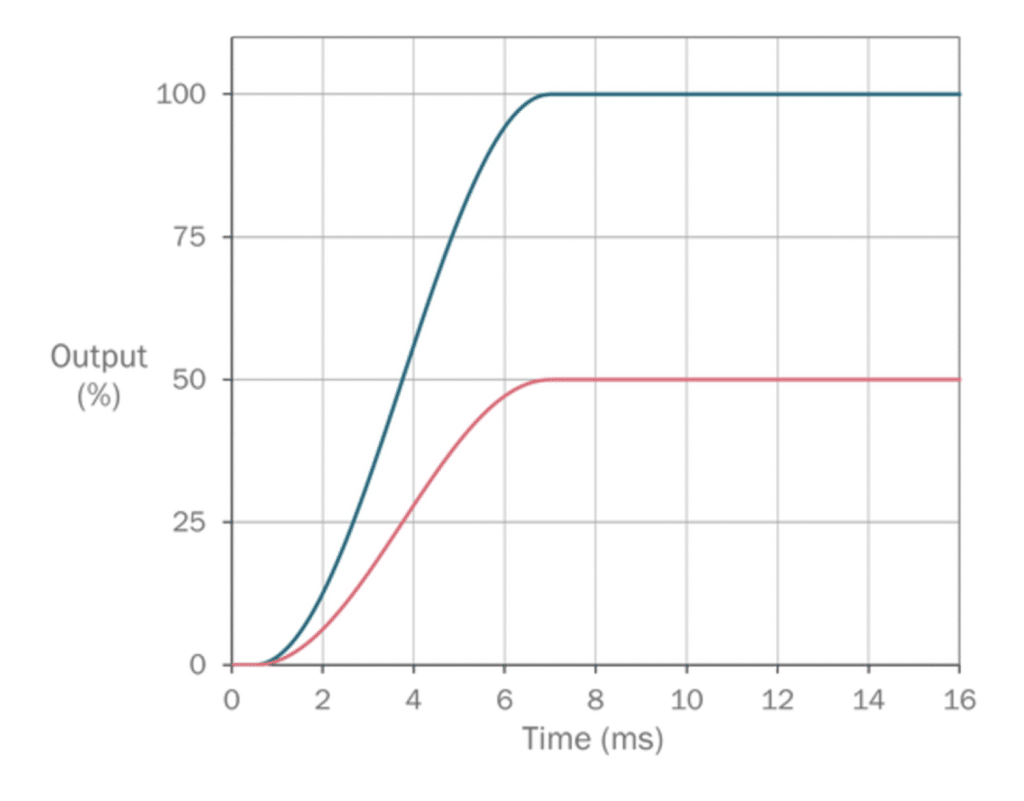

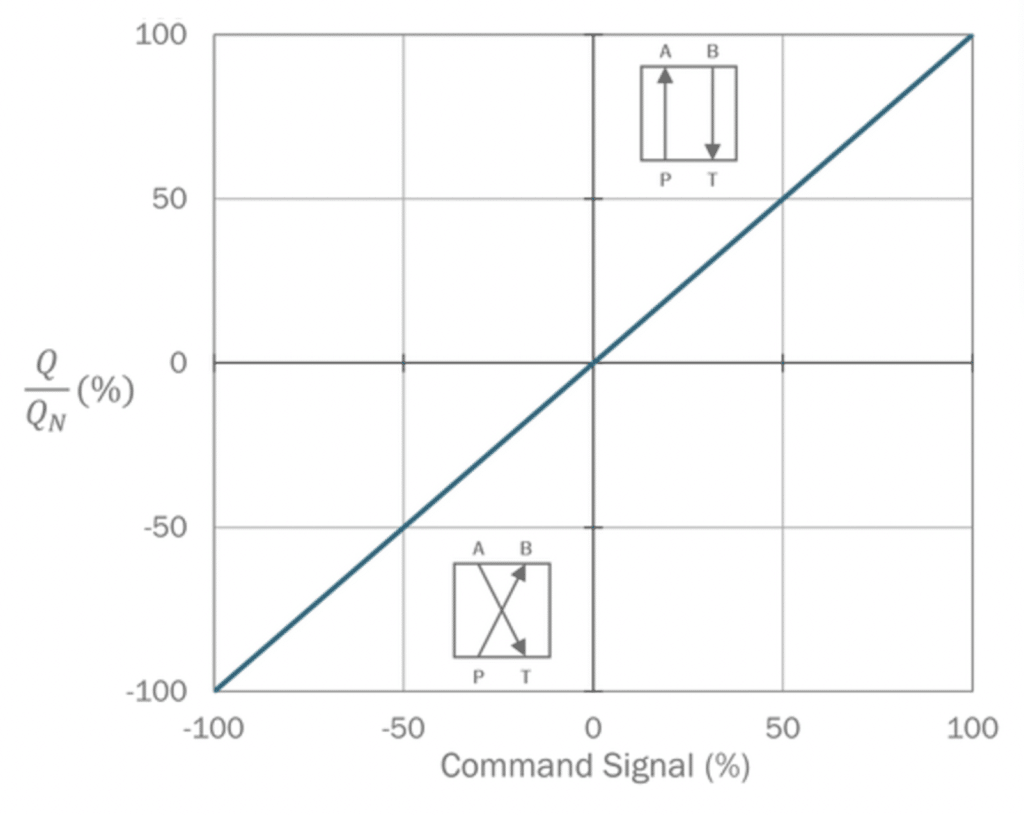

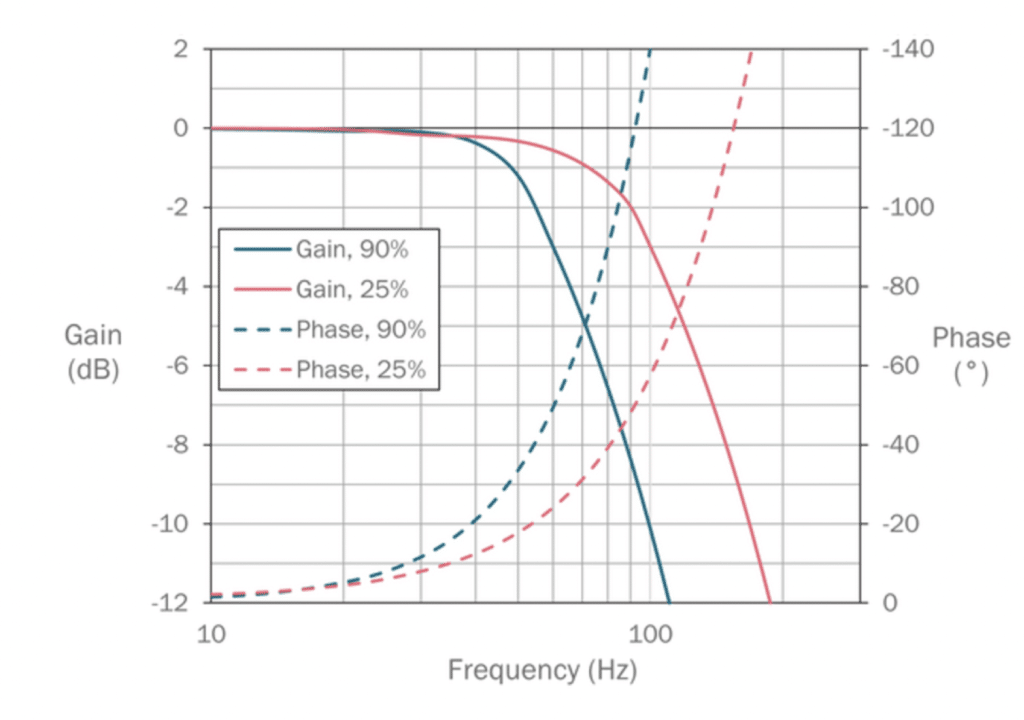

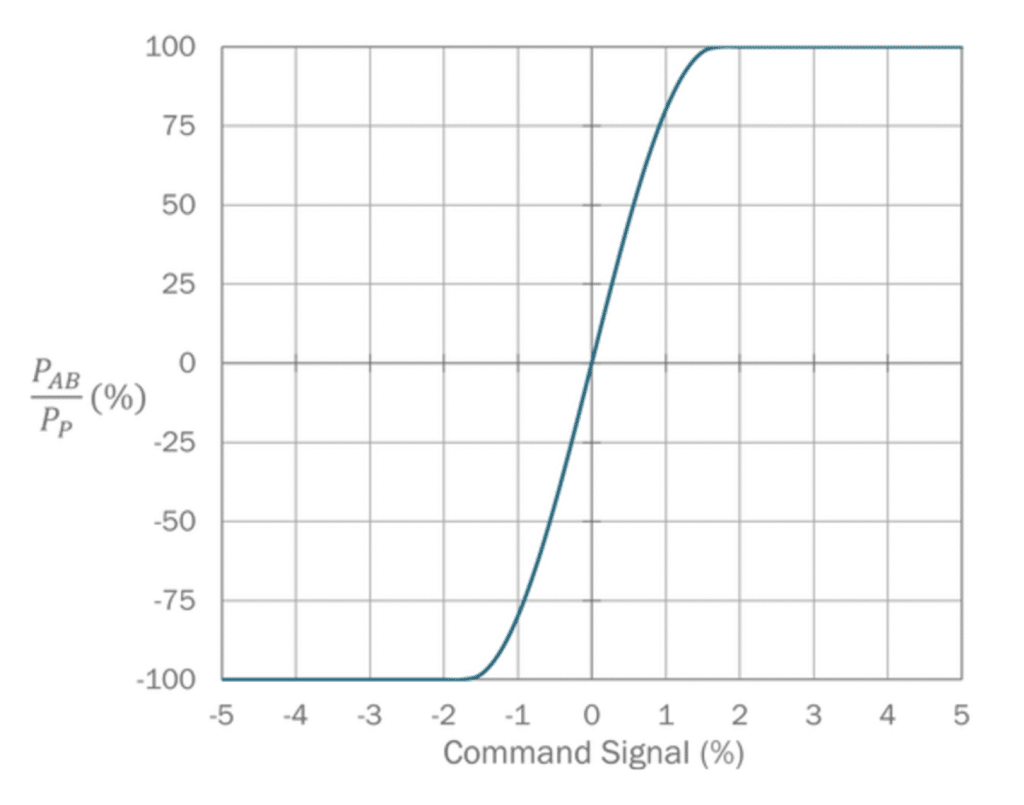

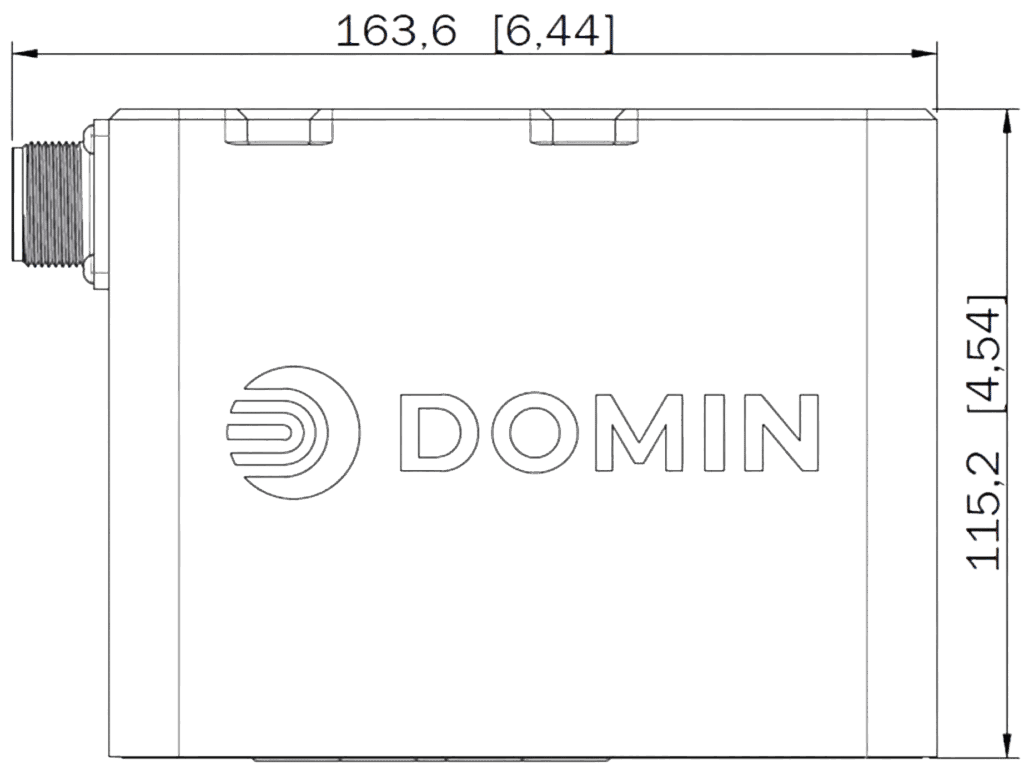

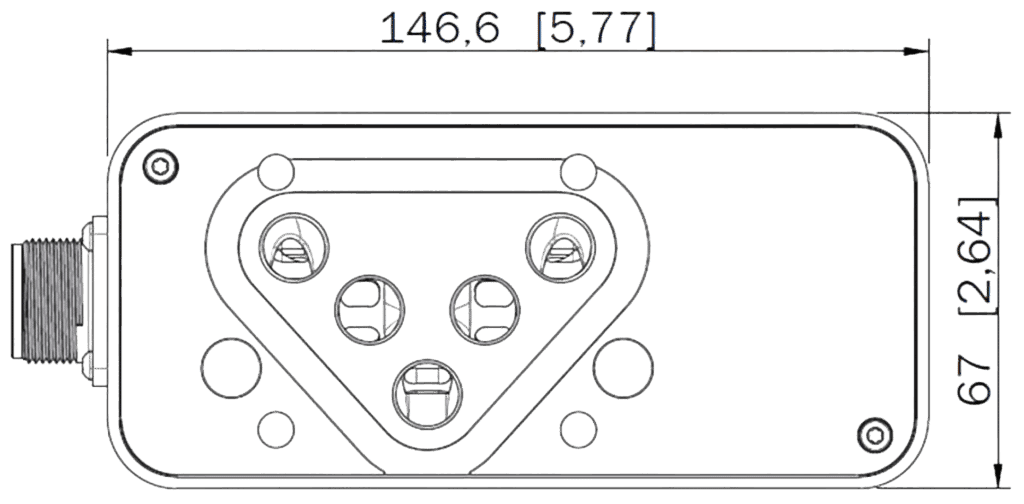

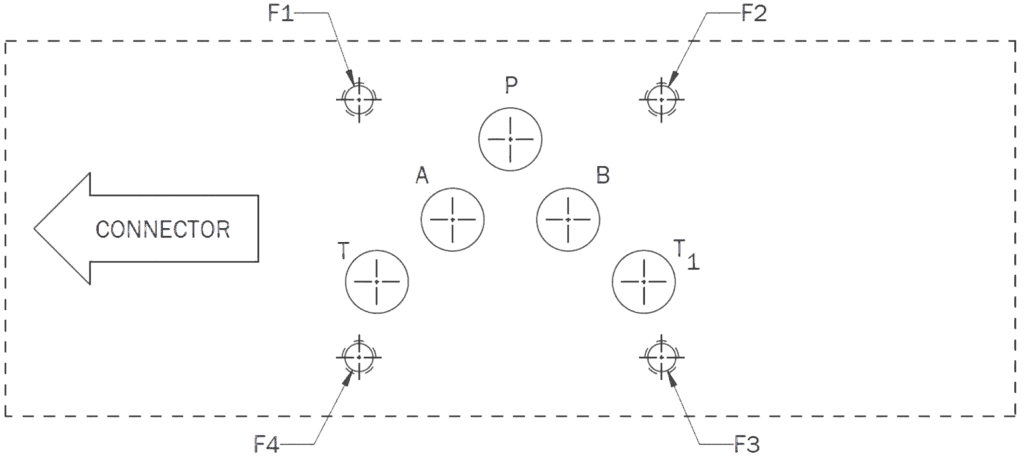

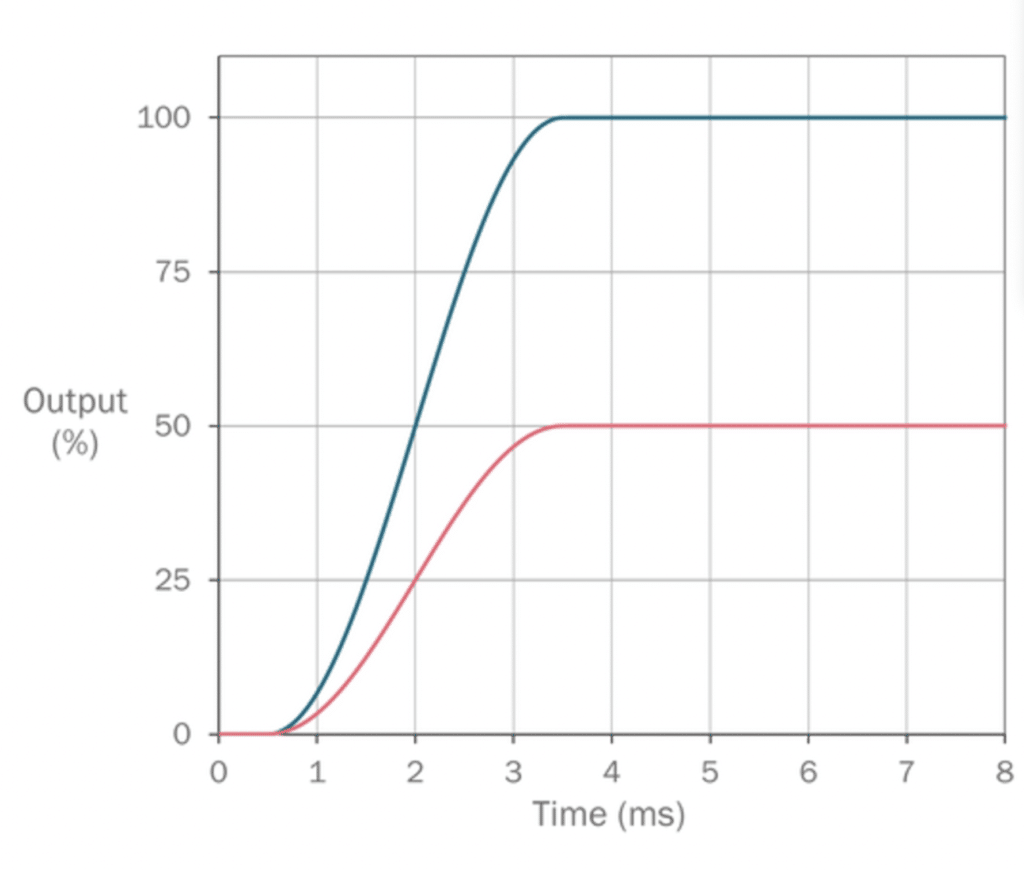

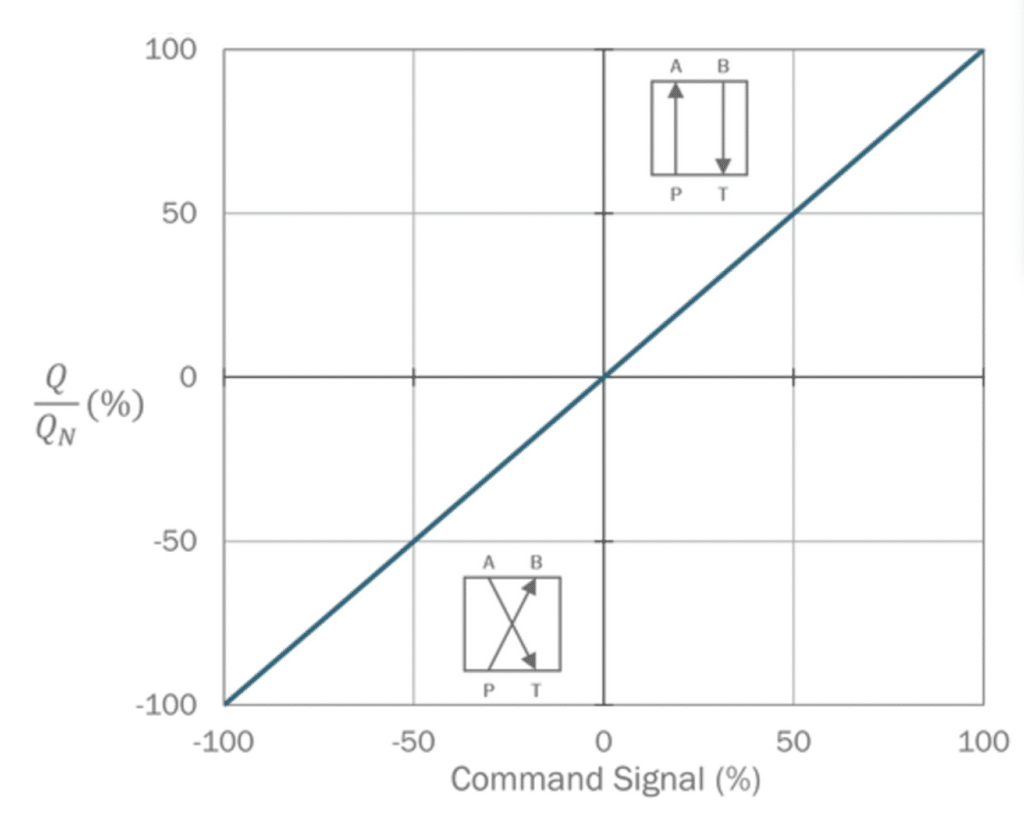

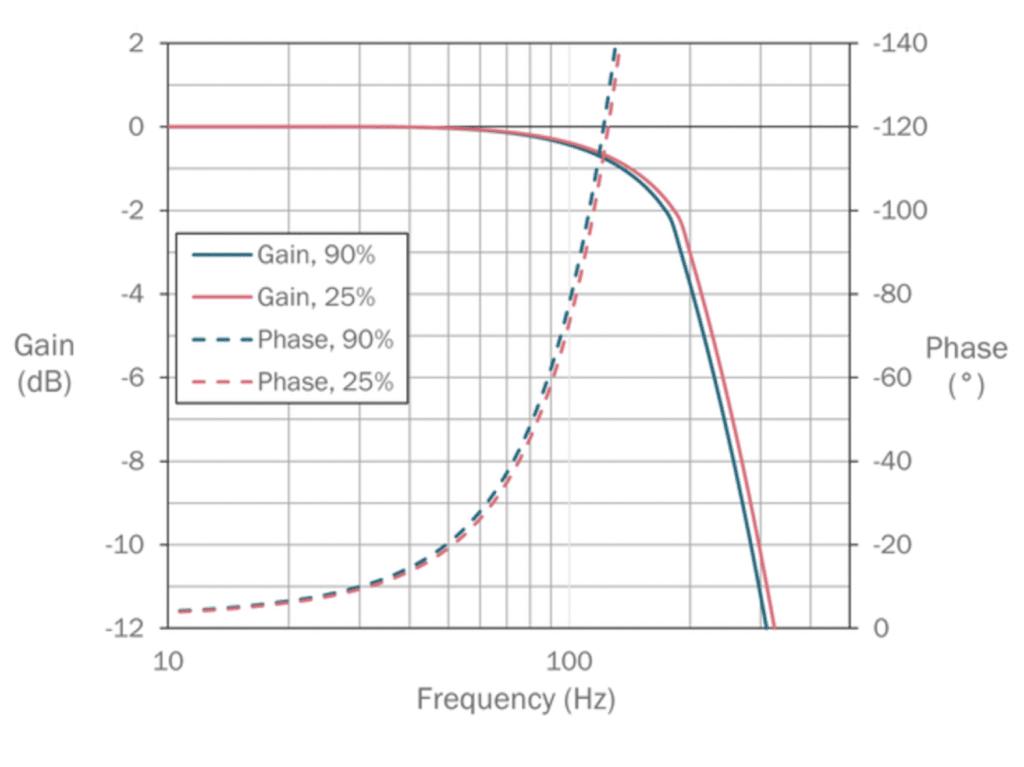

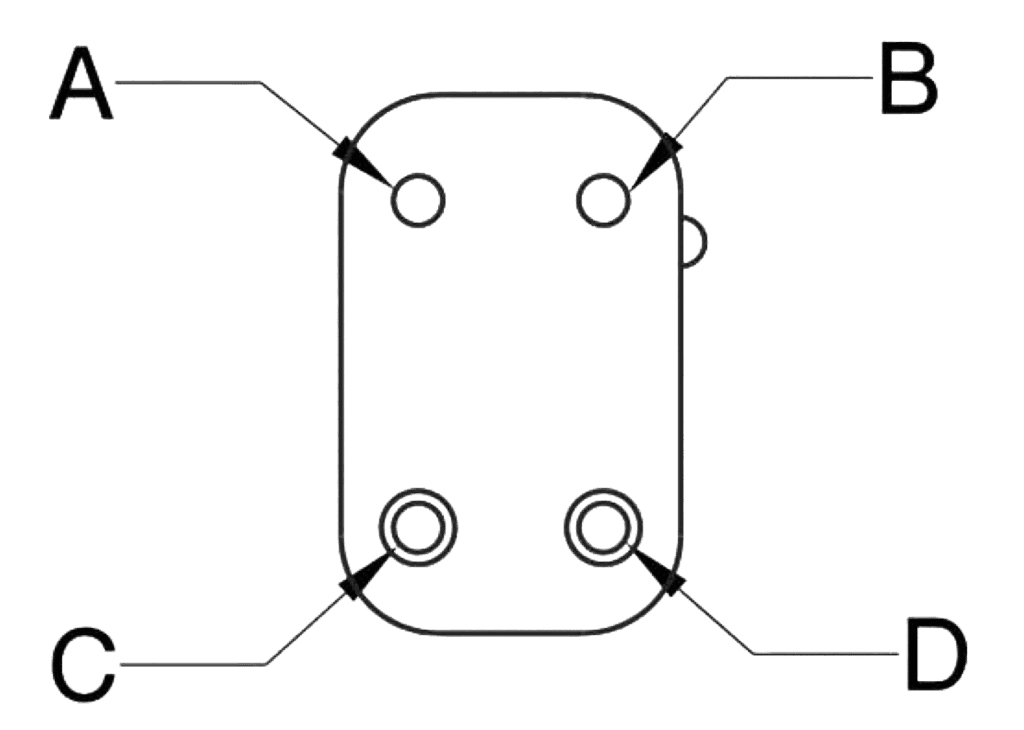

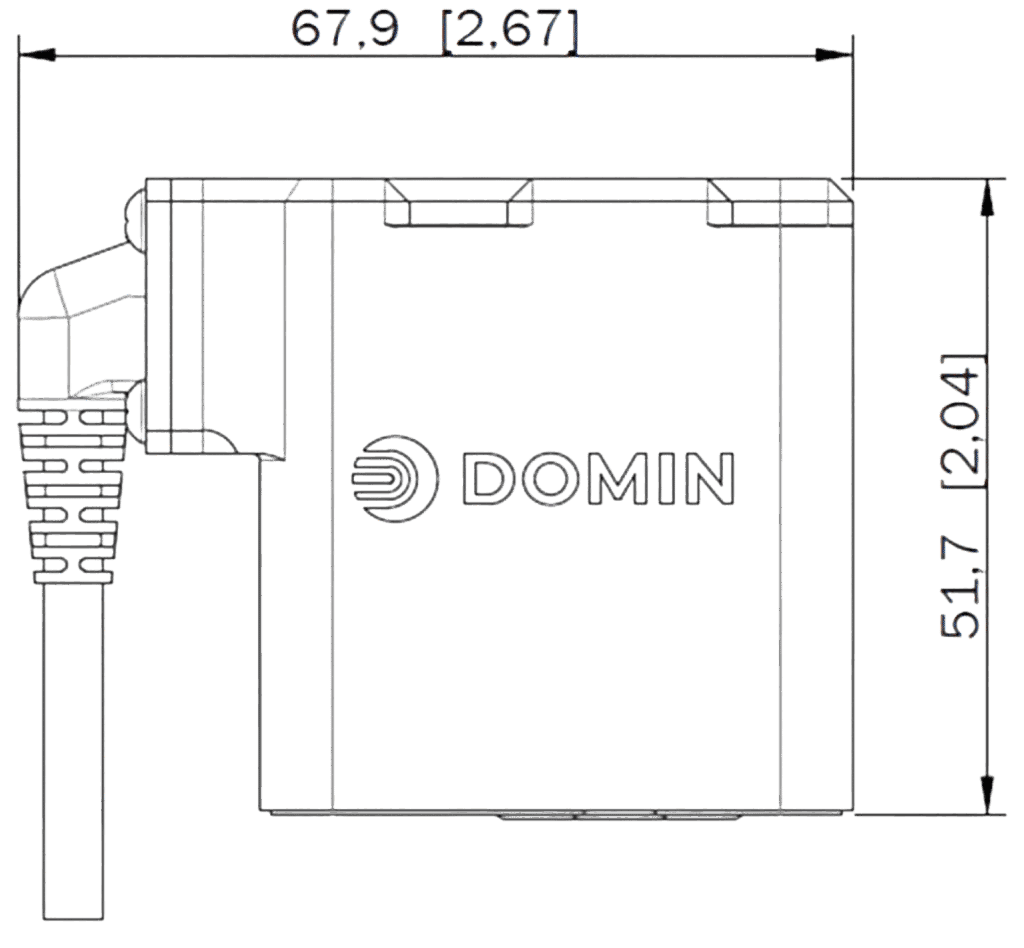

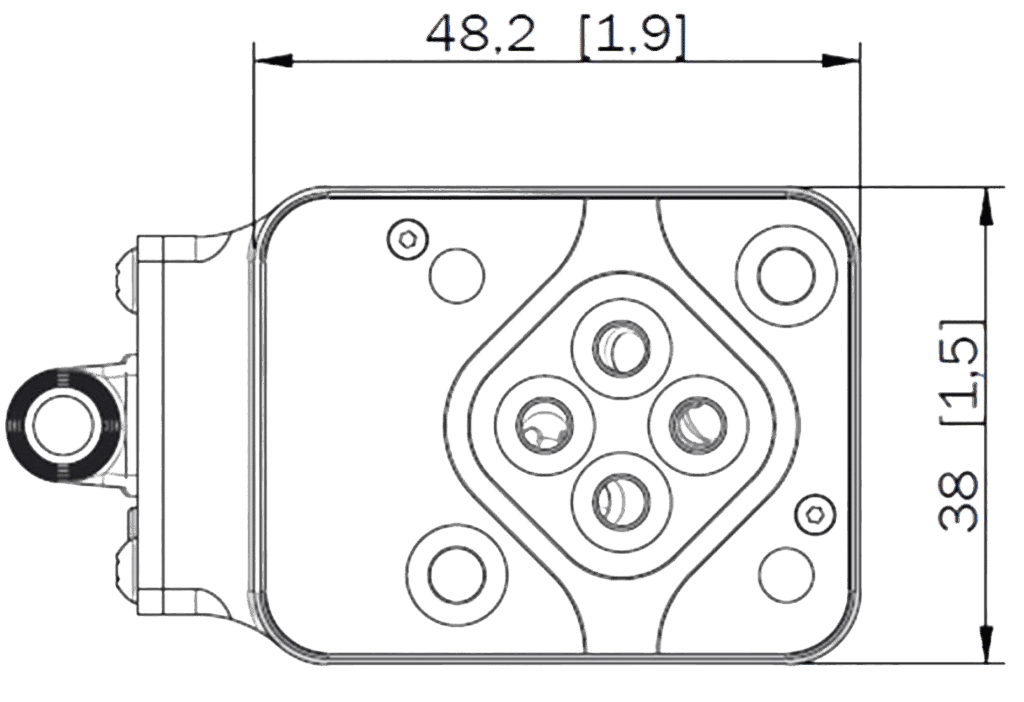

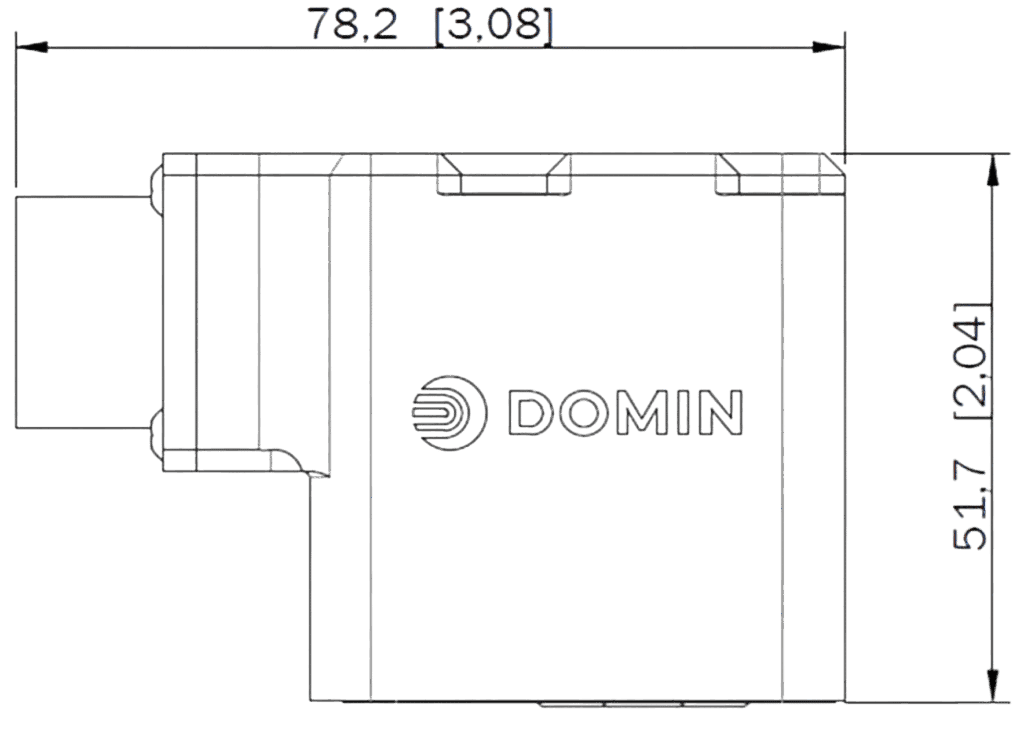

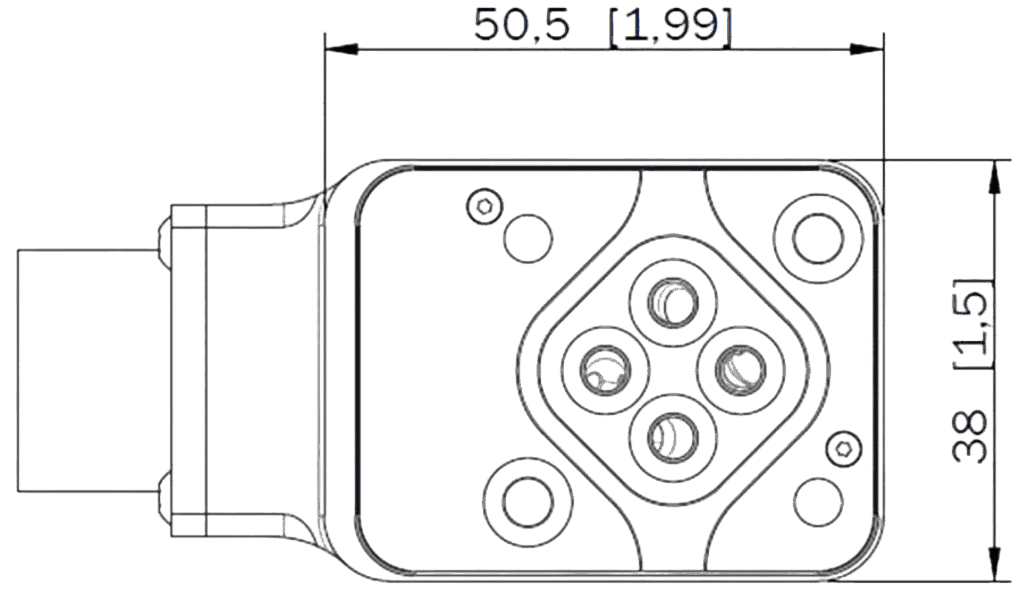

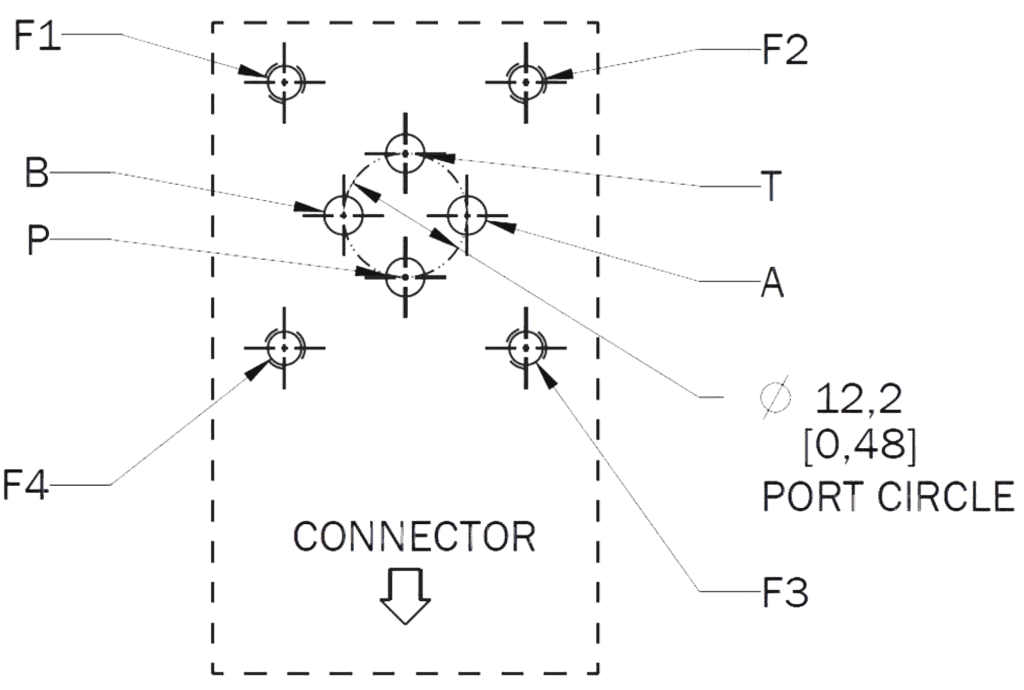

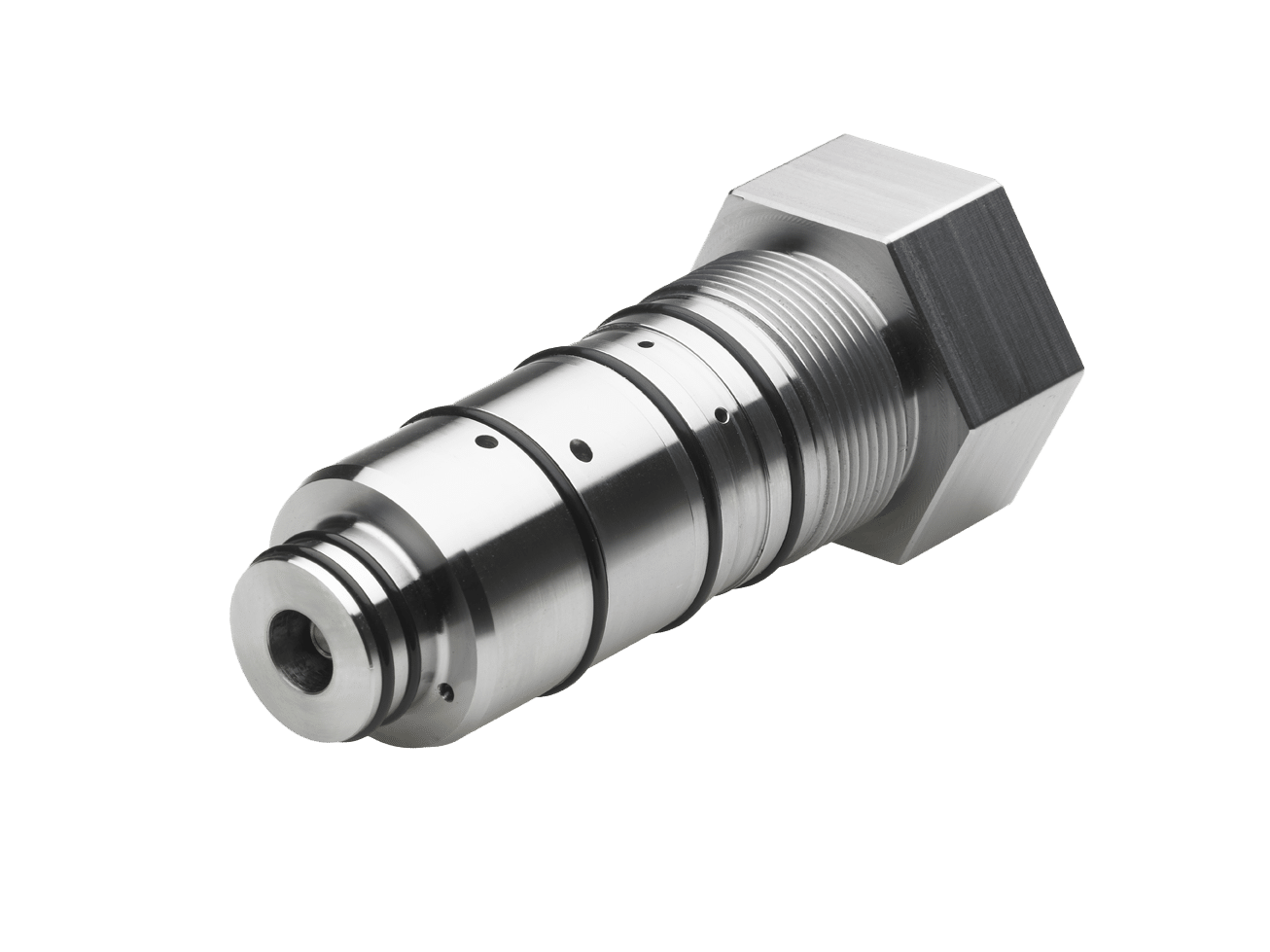

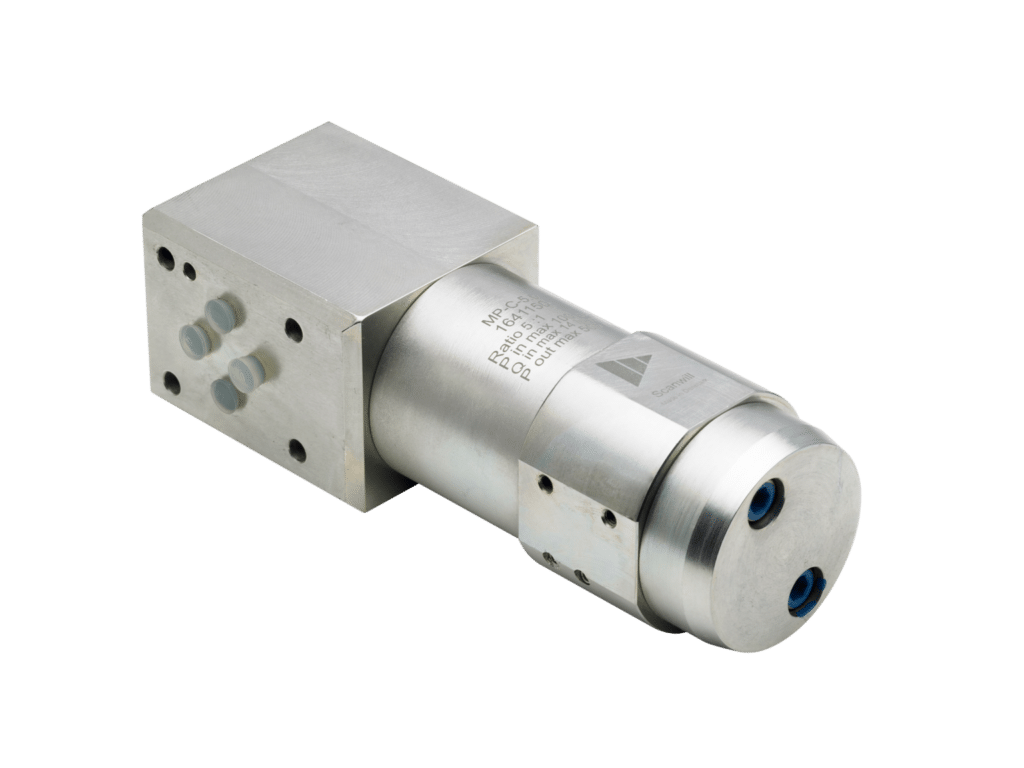

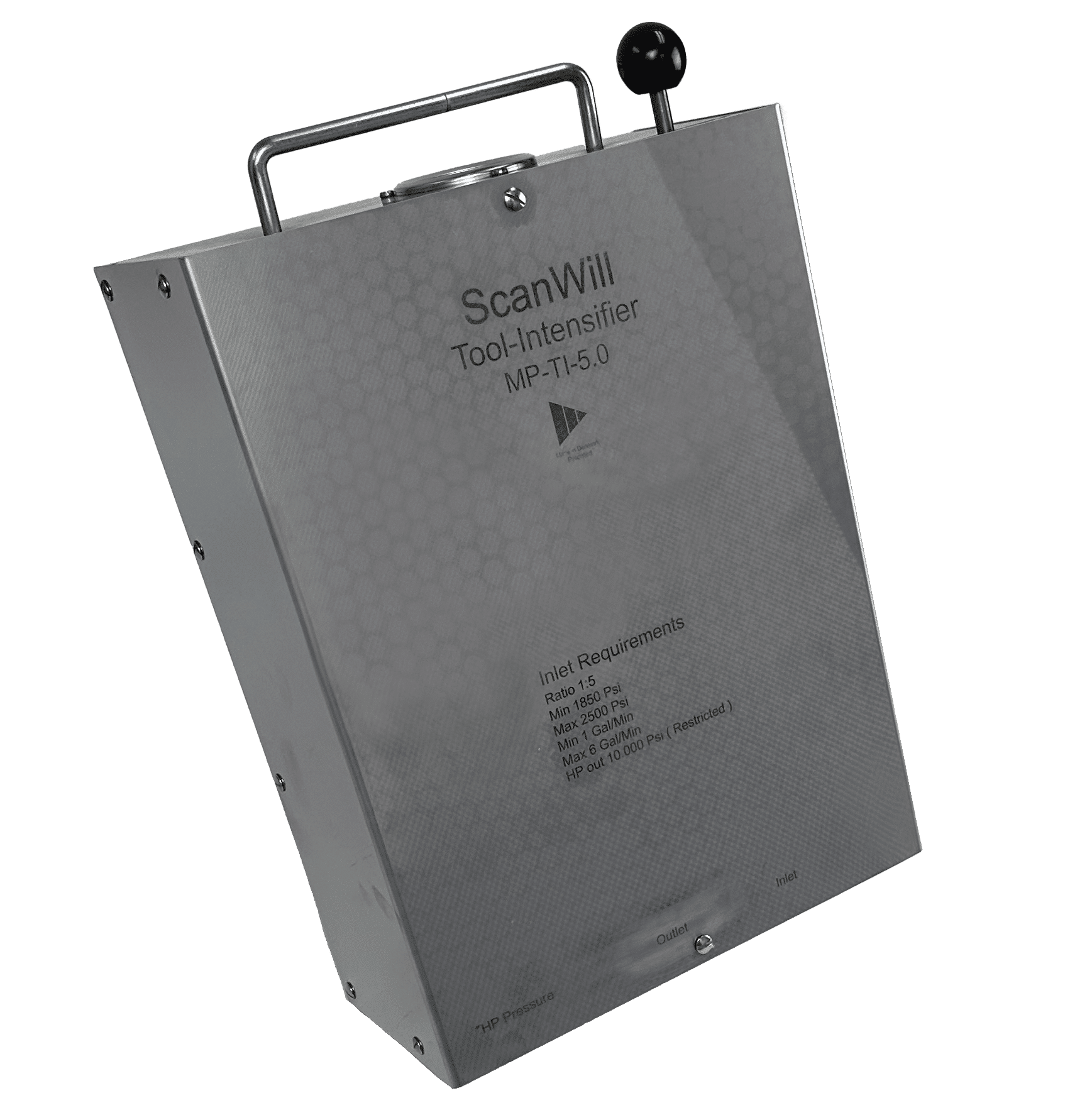

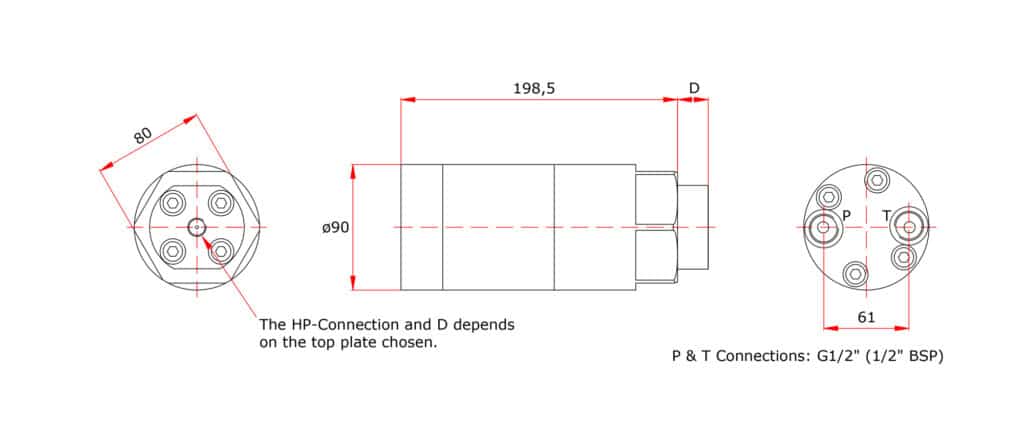

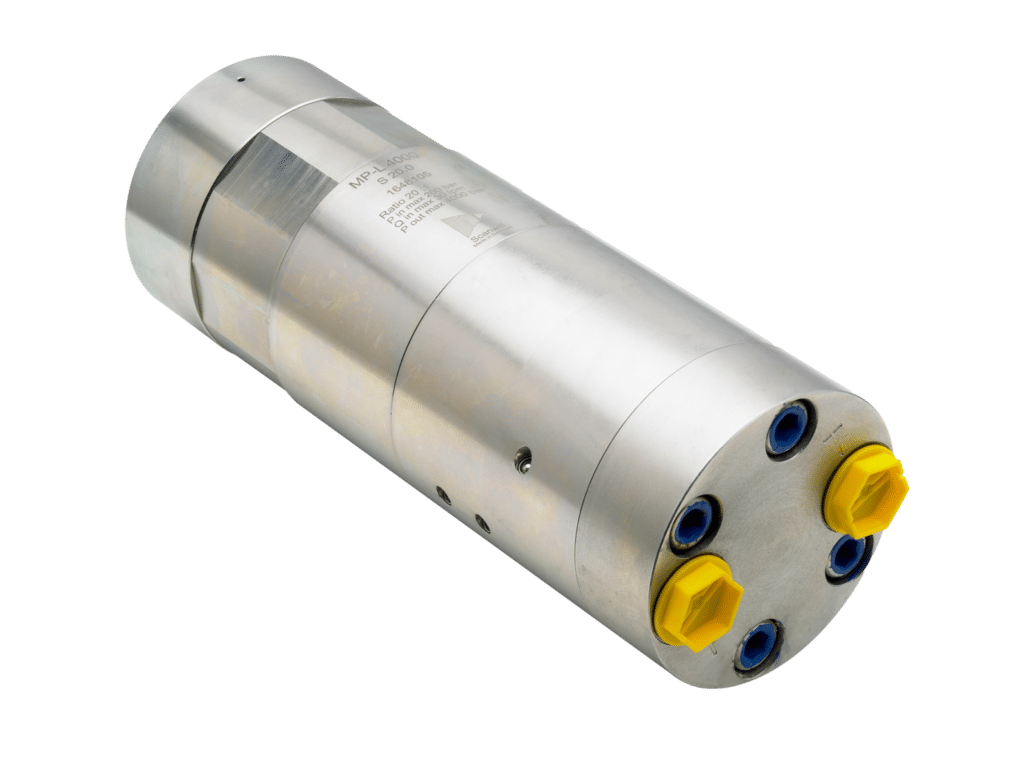

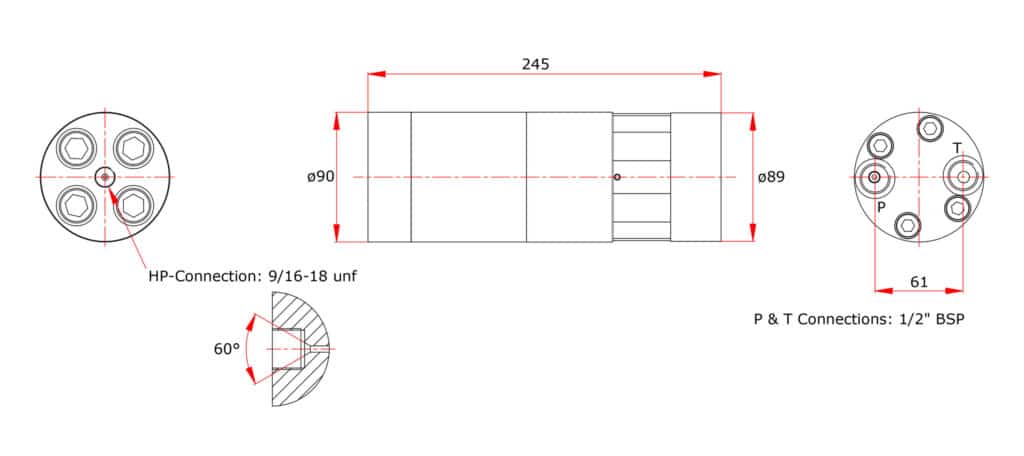

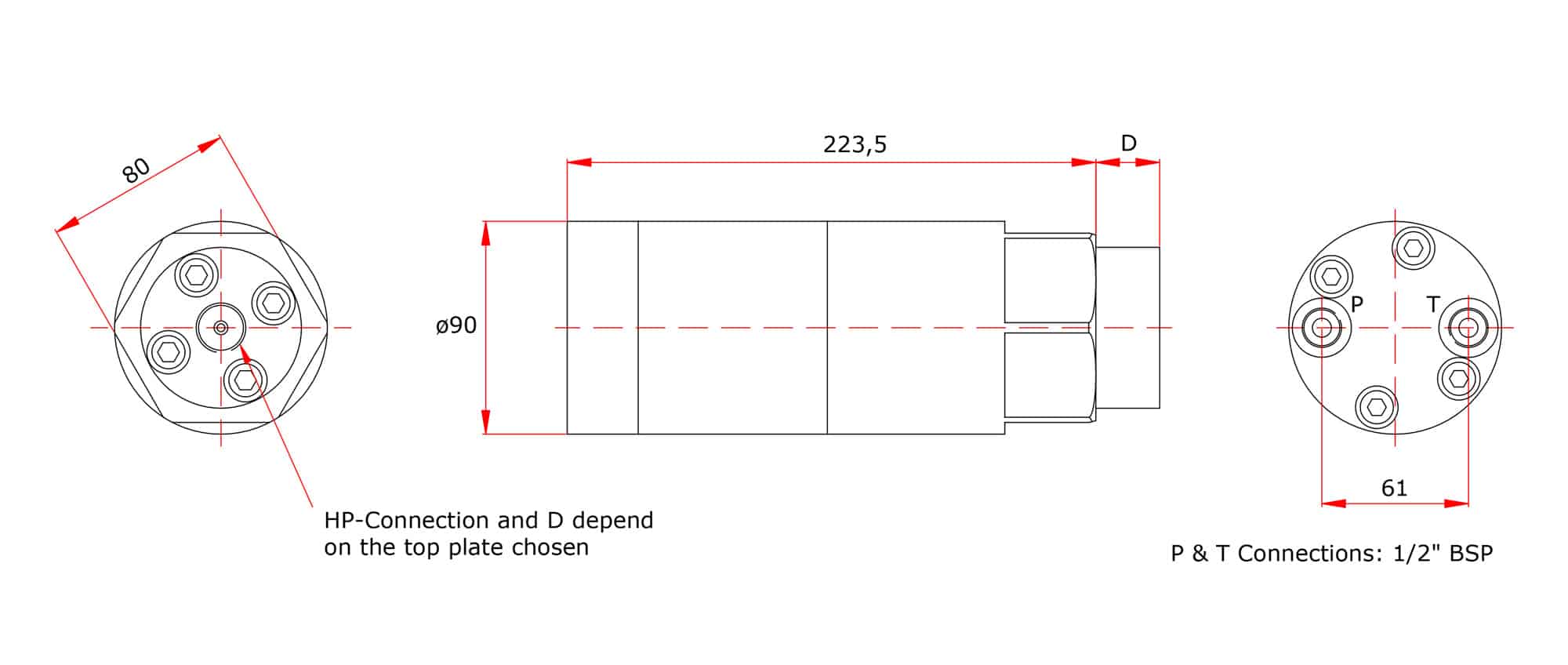

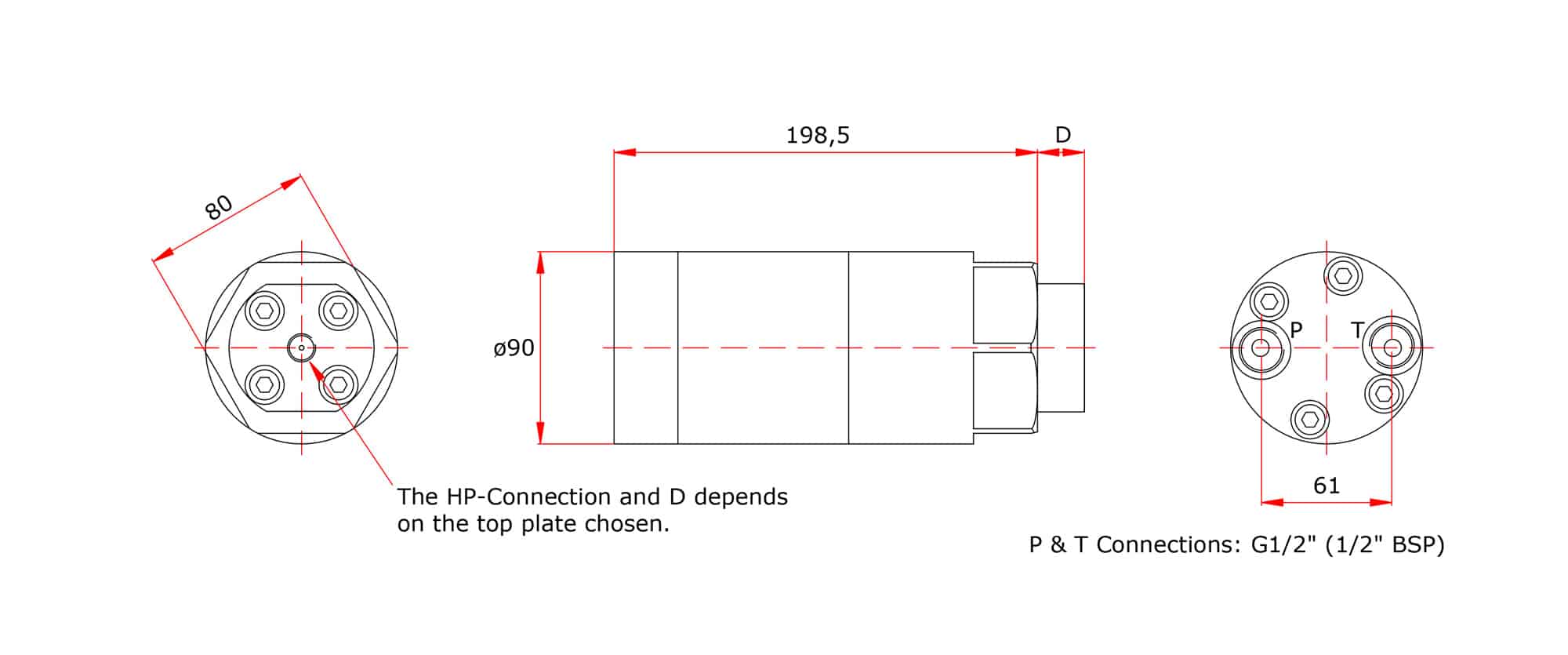

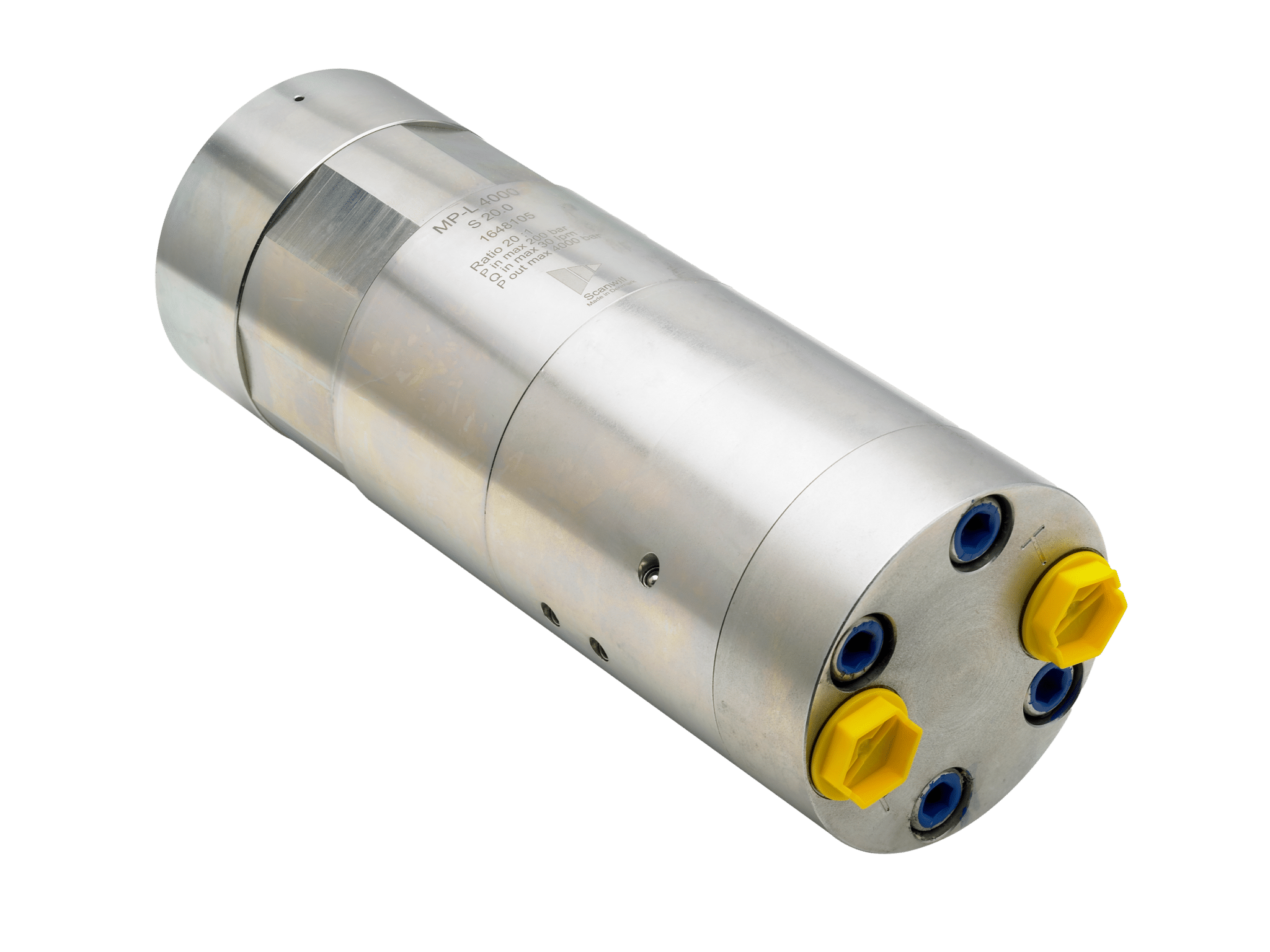

Domin Servo Valves (S Series) provide outstanding accuracy and reliability for high-precision applications and demanding industrial environments. They excel in automotive, aerospace, and testing and simulation sectors due to their a compact design that minimizes energy waste. Systems with Domin Servo Valves can achieve up to 90% greater efficiency, driving down operational costs and maximizing productivity. Upgrade easily from popular name brands (such as Moog, Parker, Bosch Rexroth, and Woodward) for a performance boost without a cost boost.

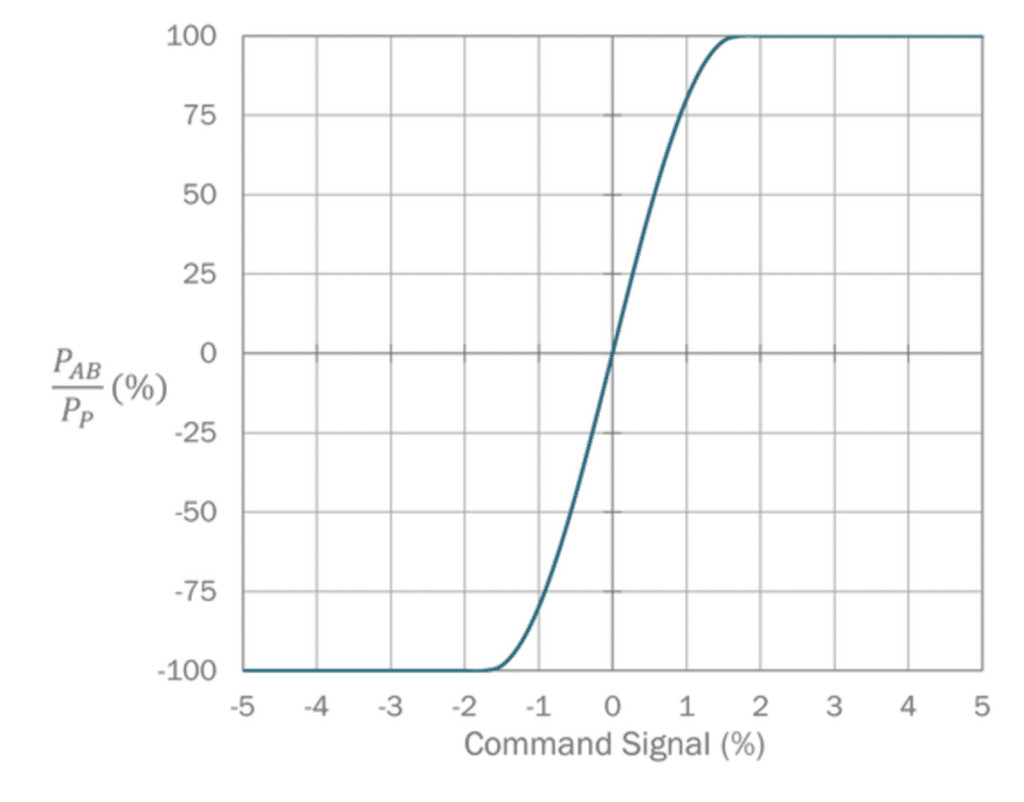

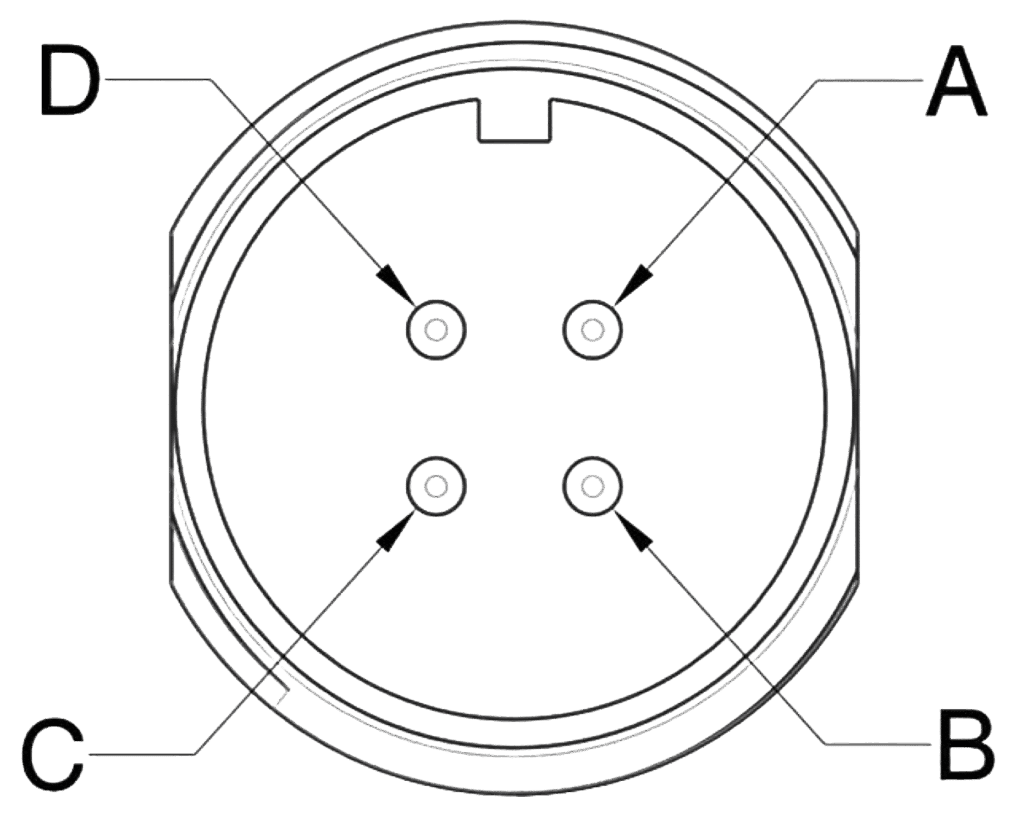

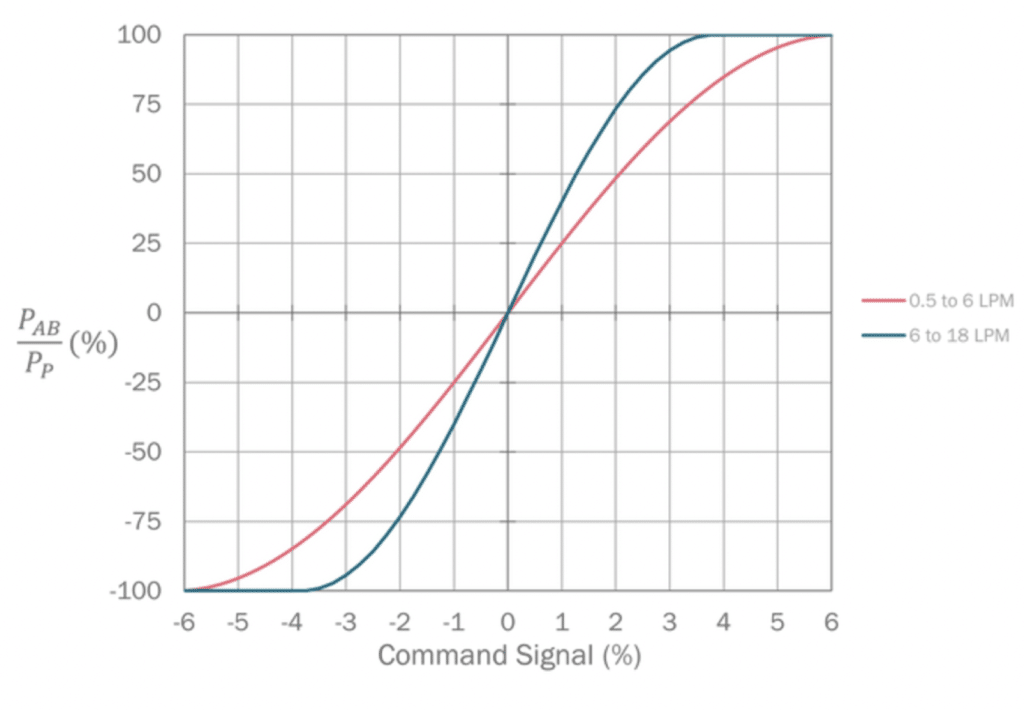

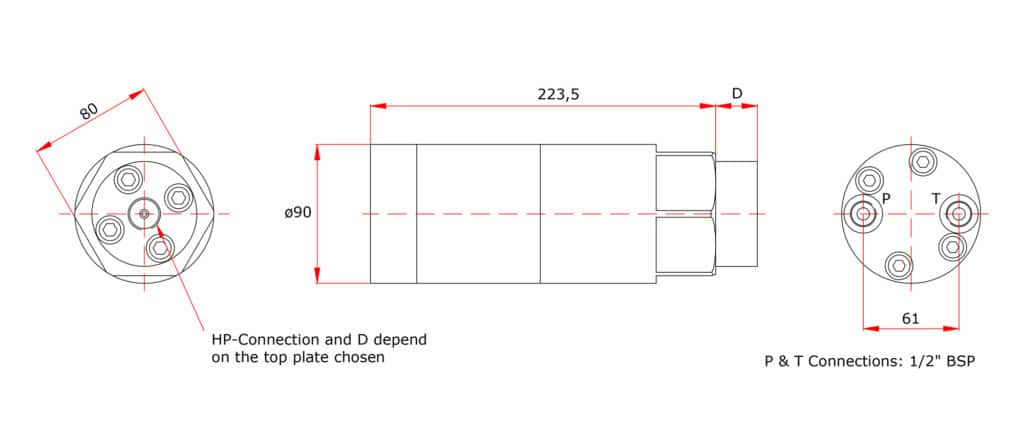

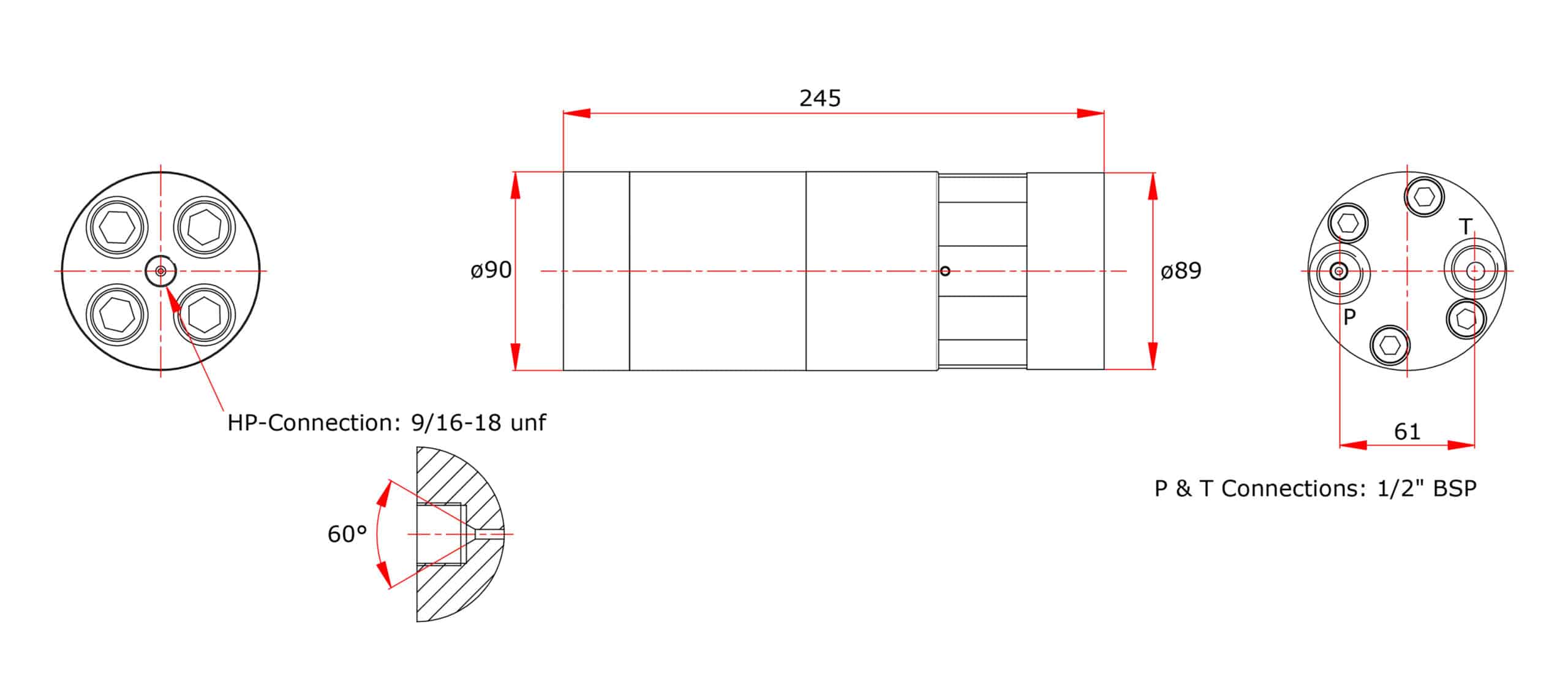

The Domin Hydraulic Proportional Valve

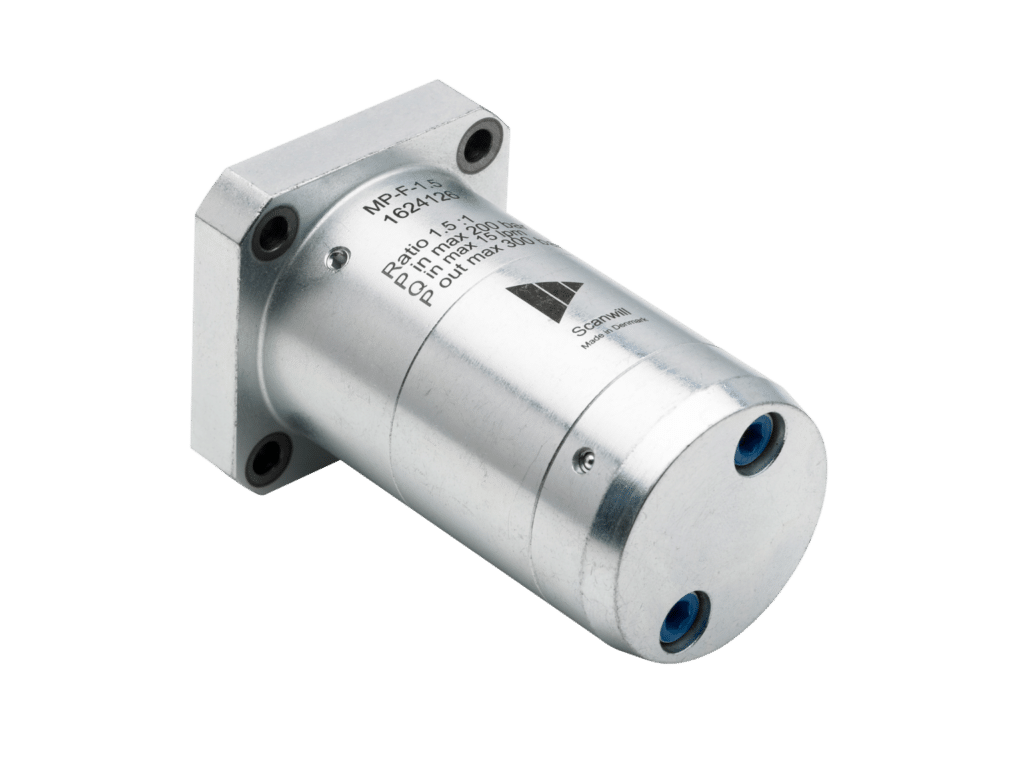

In 2026, Domin debuted their brand new proportional valves (P Series) to expand their valve offerings into the industrial and automation industries. These proportional valves were designed specifically with heavy-duty, robust applications in mind. Domin P Series Valves are ideal for applications that do not require as of a high response rate as the S Series offers. The P6 Pro and the P10 Pro offer accessible pricing for high-volume industrial applications in an easy-to-integrate, compact valve.

Why Buy From IC-Fluid Power?

Local Engineers As Your First Contact. Technical Help the Whole Way Through.

Finding the best servo valve is only the first step. The right support ensures that your servo valve doesn’t just arrive, it delivers. That’s why inquiries are handled directly by engineers, not sales reps. From the first conversation, customers receive informative replies and practical recommendations to keep projects moving quickly and to get customers the answers they need.

With decades of hydraulic experience among our team, selecting the right Domin valve, solving a system issue, or planning for a new application is easy. The goal is always to provide accurate, actionable support without unnecessary delays.

Beyond selection and setup, we pride ourselves on fast, complete service. Access to local expertise means issues are resolved faster, reducing downtime and keeping operations running smoothly. Rather than wading through customer support forms and fighting time zone differences, we answer phone calls (a real human!) within 2 rings and respond to emails within 1 business day.

The Lead Time Zero Initiative. Get Your Domin Servo Valve in Days, Not Months.

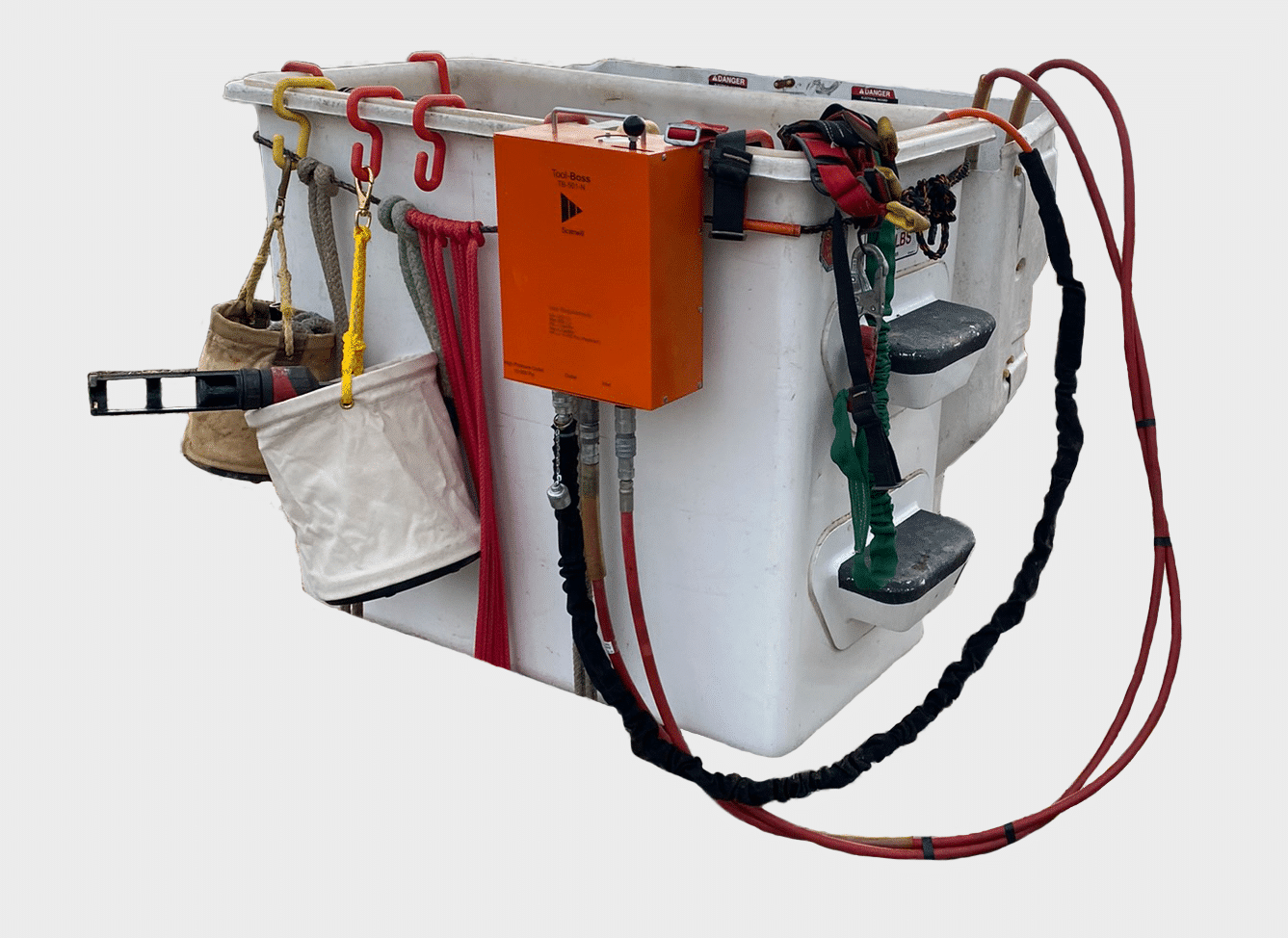

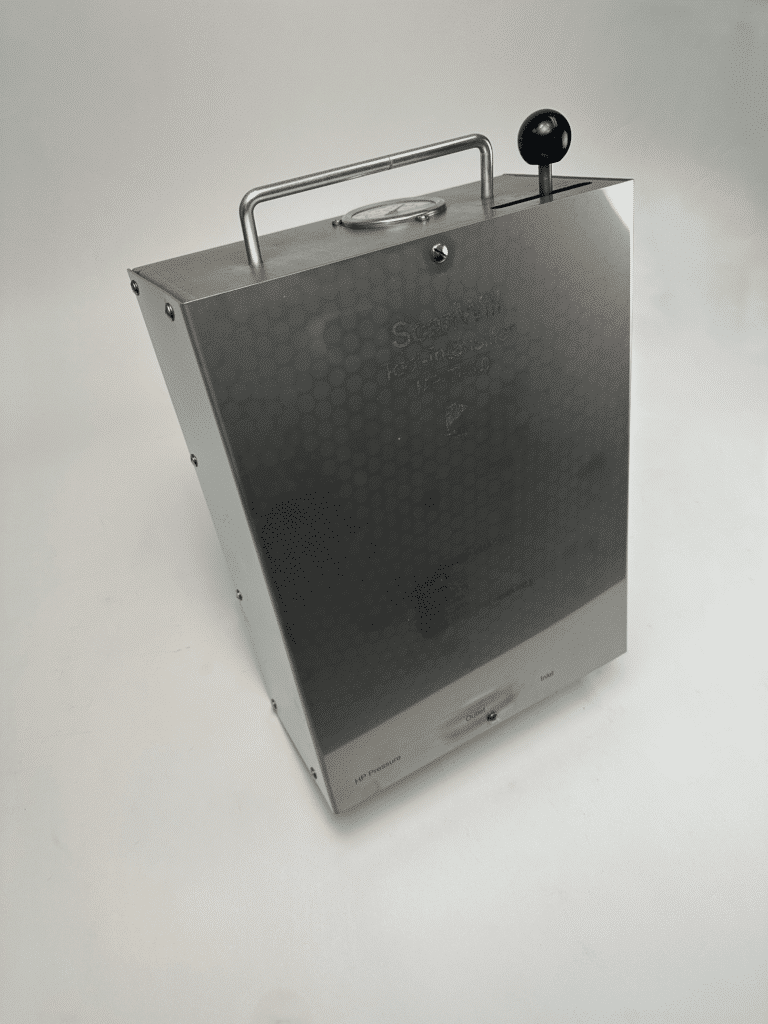

Long lead times have long been an industry norm, often stretching 12–16 weeks for critical components. Domin’s Lead Time Zero initiative changes that model. Through a global network of trusted partners, including IC-Fluid Power in the US, the most in-demand valves (S4 Pro, S6 Pro, S10 Pro) are in stock today, available directly from IC-Fluid’s Ohio warehouse.

Though we are situated in Ohio, we are close to major transportation hubs for optimal shipping. Even if you are not located in the Midwest, we offer fast shipping for minimal procurement risk and downtime.

For engineers and operations teams, this means immediate access to high-performance valves that can ship the same day or next. Reduced procurement risk and minimized downtime mean greater confidence in meeting project timelines and maintaining system performance.